Device and method for increasing capacity and improving efficiency of coal mill based on lignite

A coal mill and lignite technology, which is applied in steam engine installations, dryers, mechanical equipment, etc., can solve the problems of low combustion efficiency of boilers and insufficient output of coal mills, so as to reduce operating costs, improve coal adaptability and The effect of coal mill output and temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

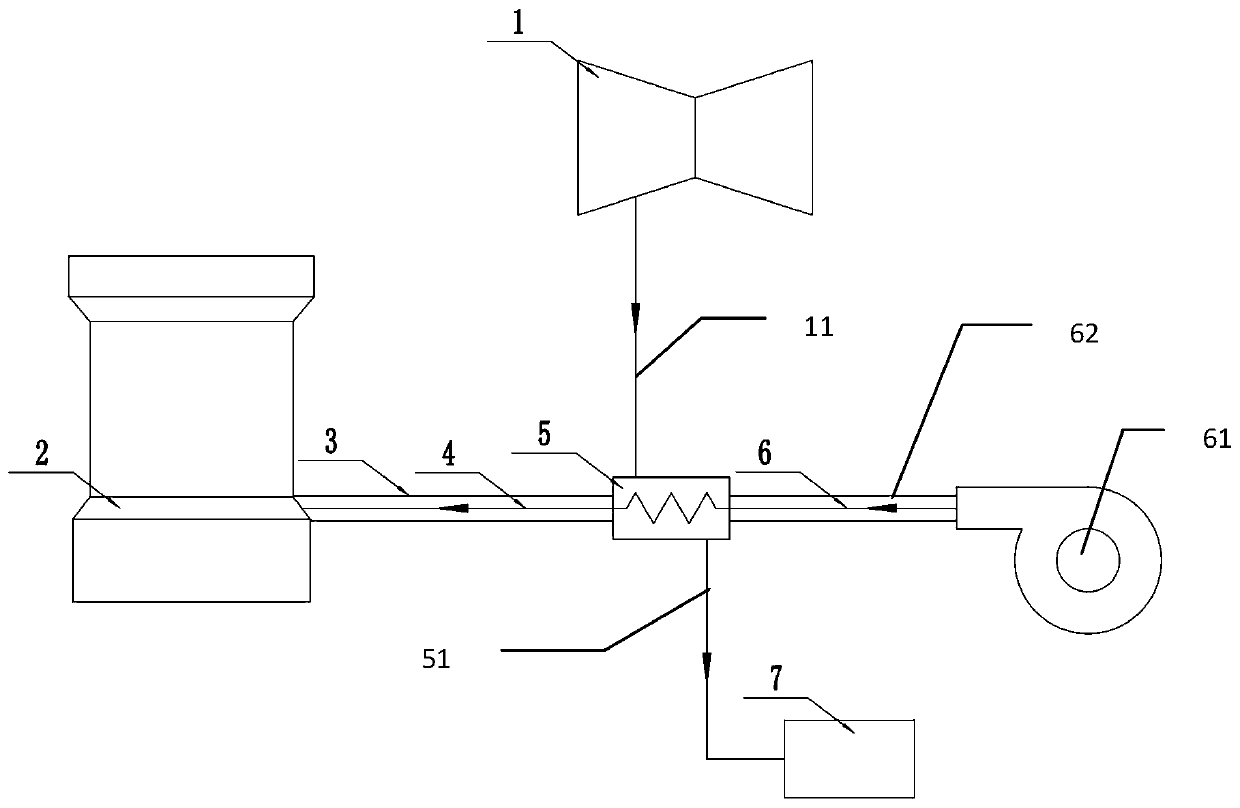

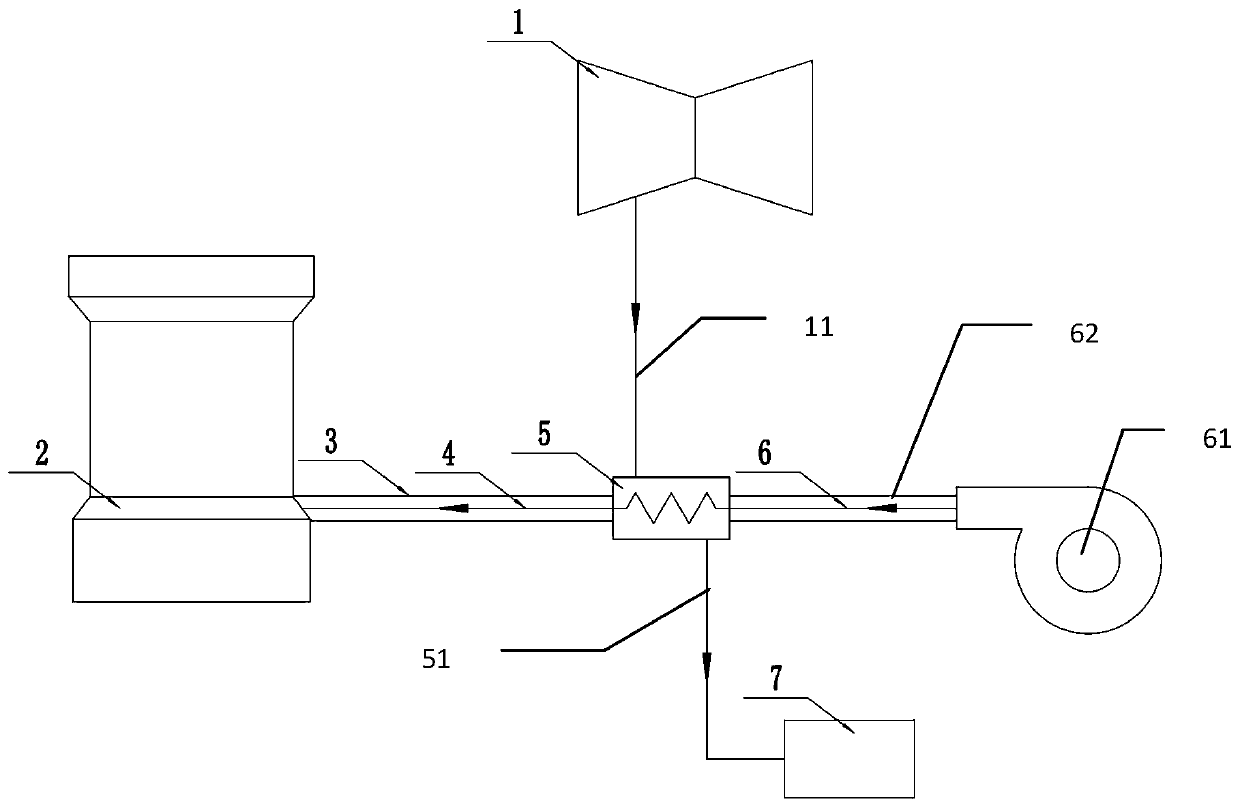

[0029] Such as figure 1 As shown, the capacity-increasing and efficiency-improving device for a coal mill of the present invention includes: a steam turbine 1; a coal mill primary air chamber 2; an inlet primary air duct 3; a reheating primary air 4; a steam heat exchanger 5; a hot primary air 6 ; Primary fan 61; No. 3 high-pressure heater 7. Among them, the high-temperature superheated steam pipe 11 drawn from the steam turbine 1 is connected to the steam heat exchanger 5; the steam heat exchanger 5 is connected to the coal mill primary air chamber 2 through the inlet primary air duct 3; the steam heat exchanger 5 is connected to the three The No. high pressure heater 7 is connected; the primary fan 61 is connected with the steam heat exchanger 5 through the hot primary air pipeline 62 .

[0030] Wherein, the steam heat exchanger 5 may be a casing heat exchanger.

[0031] The present invention is based on the method for increasing the capacity and efficiency of a coal pulve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com