Low-smoke-intensity and high-sulfur fixation adhesion agent

A technology of binder and consolidating agent, applied in the field of chemical industry, can solve problems such as deficiencies, and achieve the effects of good mechanical properties, good waterproofness, and high cold and hot strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

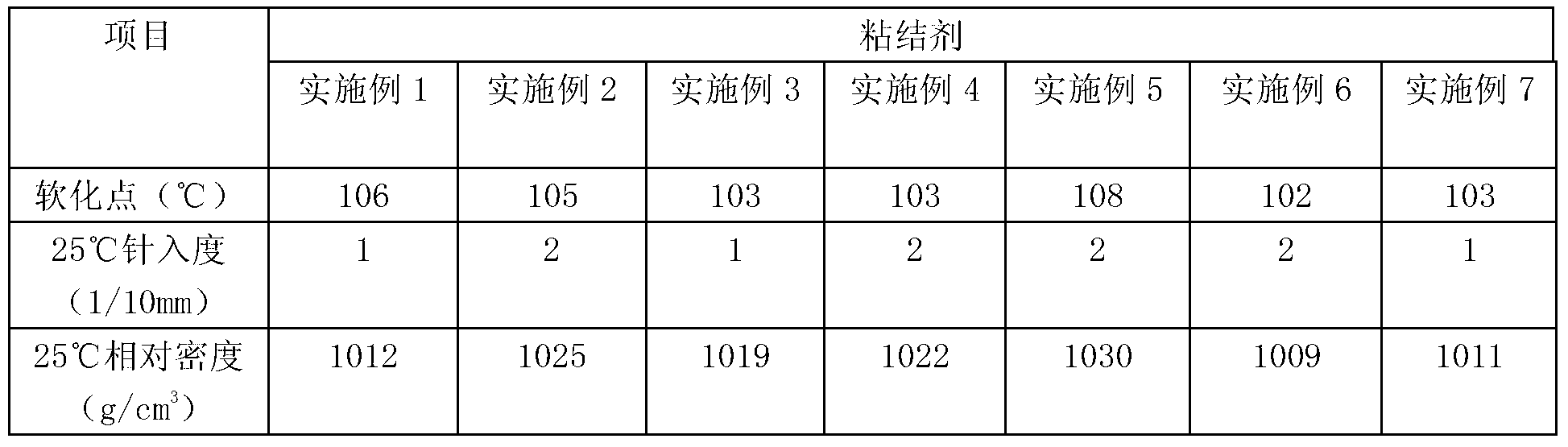

Examples

Embodiment 1

[0012] A binder with low smoke and high sulfur-fixing performance, which is composed of the following components in parts by weight: 40 parts of magnesium oxychloride cement, 10 parts of bentonite, 20 parts of waste furnace slag from steelmaking furnace, 5 parts of graphite tailings, phosphoric acid 2 parts of trisodium, 8 parts of sodium silicate, 3 parts of magnesite, 7 parts of magnesium chloride, and 5 parts of polyethylene glycol; each component was mixed by weight, stirred for 48 hours, and after being powdery, the It can be obtained by pressing and forming under pressure.

Embodiment 2

[0014] A binder with low smoke and high sulfur-fixing performance, which is composed of the following components in parts by weight: 30 parts of magnesium oxychloride cement, 20 parts of bentonite, 20 parts of waste furnace slag from steelmaking furnace, 5 parts of graphite tailings, phosphoric acid 2 parts of trisodium, 8 parts of sodium silicate, 3 parts of magnesite, 7 parts of magnesium chloride, and 5 parts of polyethylene glycol; each component was mixed by weight, stirred for 48 hours, and after being powdery, the It can be obtained by pressing and forming under pressure.

Embodiment 3

[0016] A binder with low smoke and high sulfur-fixing performance, which is composed of the following components in parts by weight: 35 parts of magnesium oxychloride cement, 15 parts of bentonite, 20 parts of waste furnace slag from steelmaking furnaces, 5 parts of graphite tailings, phosphoric acid 2 parts of trisodium, 8 parts of sodium silicate, 3 parts of magnesite, 7 parts of magnesium chloride, and 5 parts of polyethylene glycol; each component was mixed by weight, stirred for 48 hours, and after being powdery, the It can be obtained by pressing and forming under pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com