Oxygen-enriched gas producing method for hybrid gas furnace

A technology for mixing gas and producing furnace, which is applied in the directions of manufacturing combustible gas, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of low gas calorific value, etc., and achieves improved gas calorific value, reduced efficiency, and good economic benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

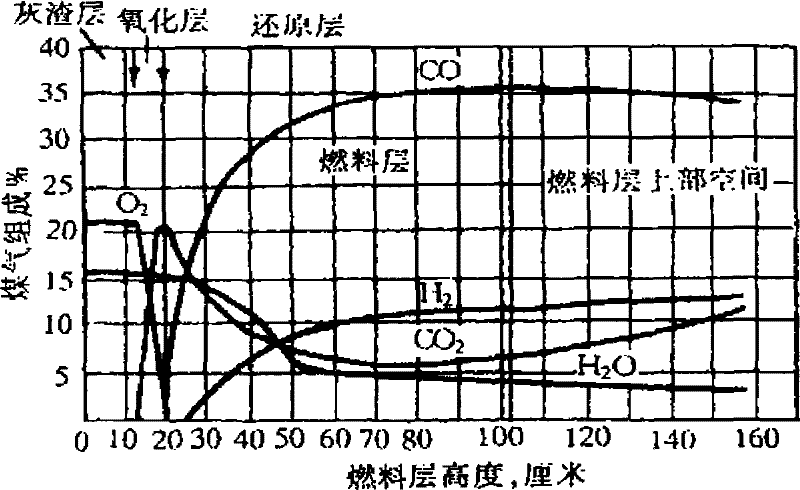

Method used

Image

Examples

Embodiment 1

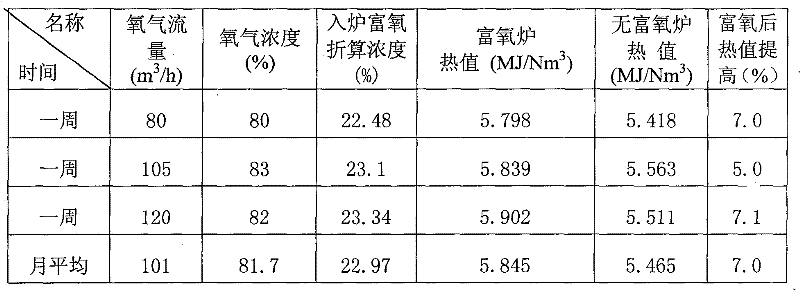

[0048] July 2007, press 80m on selected furnace 3 / h, 100m 3 / h, 120m 3 The flow rate of oxygen per hour is passed into the air pipe, and the preliminary exploration of oxygen-enriched gas production has been carried out. Since the device is in the initial stage of load operation, the device starts and stops frequently due to equipment reasons, and the total gas production is about 350m 3 / h, the concentration is greater than 80%, with 15 # The furnace is used as the main test furnace, and the excess oxygen is fed into 13 # The furnace may be emptied, during which the oxide layer elongation and slagging occurred to varying degrees in the furnace. During the oxygen-enriched oxidation period, the furnace condition was relatively stable, and the indicators improved to a certain extent. When the oxygen enrichment is put into or withdrawn, the furnace condition is not easy to grasp, and the gas quality fluctuates greatly, and the furnace was forced to be withdrawn for maintenan...

Embodiment 2

[0055] In August 2007, the oxygen generation system shut down 5 times in total, 2 of which were program-controlled valve failures, which took a long time, 2 shut downs due to poor connection of CPU backplane wiring, and 1 shut down due to planned repair of the oxygen station. The production started on the 15th. Due to the experience of last month, the furnace condition control is relatively stable, and 7 of the 66 calorific value analysis data exceed 6.0MJ / Nm 3 above.

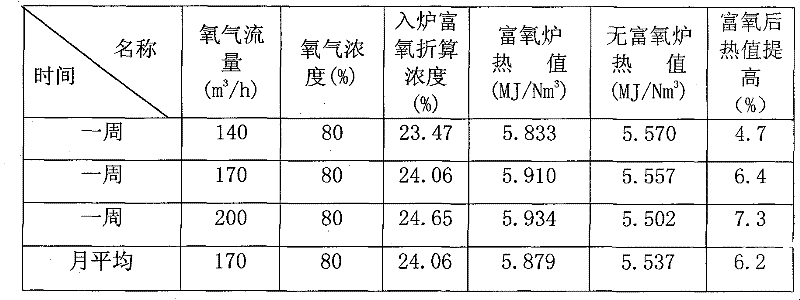

[0056] Table 2 Oxygen flow rate 140m 3 / h~200m 3 / h effect comparison

[0057]

[0058] It can be seen from Table 2 that the calorific value of the oxygen-enriched furnace has risen steadily, the quality of the medium lump coal is also relatively stable, and the carbon content of the ash is higher than that of the previous month (see Table 6).

Embodiment 3

[0060] In September 2007, the oxygen-enriched content continued to be increased as planned. Whenever the oxygen flow rate was increased or decreased, the furnace condition was difficult to control; in addition, the supply of anthracite from outside was tight in September, and the bottom coal and the anthracite poured into the open storage yard accounted for a large part For a large proportion, the coal powder content rate is as high as 25%, and the water content is more than 5.5%, which will cause the material layer in the furnace to be easily blown over, and the material layer will partially form a wind tunnel and catch fire, which will cause the furnace temperature to rise too fast, which will easily lead to Furnace condition deteriorates, affecting gas quality and output.

[0061] Table 3 Oxygen flow rate 200m 3 / h~230m 3 / h effect comparison

[0062]

[0063] It can be seen from Table 3 that the monthly average carbon content of oxygen-enriched furnace ash is 29.20% (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com