A method suitable for preparing cold-set pellets from iron-containing sludge using composite adhesives

A technology of composite adhesive and cold-set pellets, which is applied in the field of adhesives for metallurgical ironmaking, can solve the problems of lowering the iron grade of cold-set pellets, lowering the iron-containing grade of pellets, affecting smelting energy consumption and output, etc. The effect of energy consumption, improving iron content and reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

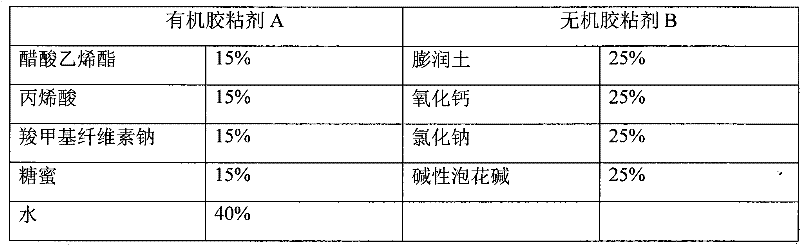

[0023] Composite adhesive formula is as follows: (calculated by weight fraction)

[0024]

[0025] Add vinyl acetate, acrylic acid, and sodium carboxymethyl cellulose into the four-neck bottle according to the proportion, then add water according to the proportion, stir at 90°C and 1500 rpm until the glue is evenly mixed, and then mix the glue Pour out the solution and cool it to room temperature, and finally mix the cooled glue solution with molasses evenly according to the proportion to obtain the organic adhesive A. Take bentonite, calcium oxide, high-temperature cement, and alkaline sodium hydroxide according to the proportion, and mix them evenly to obtain inorganic adhesive B.

[0026] According to the proportion, the organic adhesive A and the inorganic adhesive B are compounded and stirred evenly (the compounding ratio is 1: 1), and then added in the mixture of iron concentrate powder and iron-containing sludge according to the proportioning (the mixing ratio is: co...

Embodiment 2

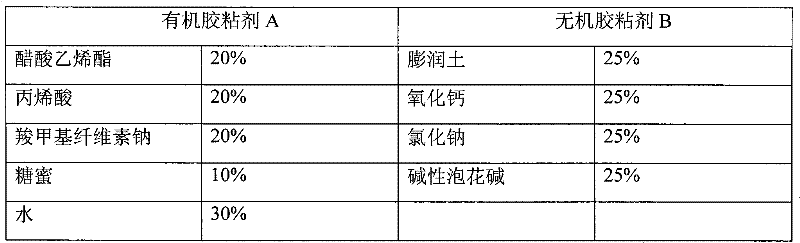

[0028] Composite adhesive formula is as follows: (calculated by weight fraction)

[0029]

[0030] Add vinyl acetate, acrylic acid, and sodium carboxymethyl cellulose into the four-neck bottle according to the proportion, then add water according to the proportion, stir at 90°C and 1500 rpm until the glue is evenly mixed, and then mix the glue Pour out the solution and cool it to room temperature, and finally mix the cooled glue solution with molasses evenly according to the proportion to obtain the organic adhesive A. Take bentonite, calcium oxide, high-temperature cement, and alkaline sodium hydroxide according to the proportion, and mix them evenly to obtain inorganic adhesive B.

[0031] According to the proportion, the organic adhesive A and the inorganic adhesive B are compounded and stirred evenly (the compounding ratio is 1: 1), and then added in the mixture of iron concentrate powder and iron-containing sludge according to the proportioning (the mixing ratio is: co...

Embodiment 3

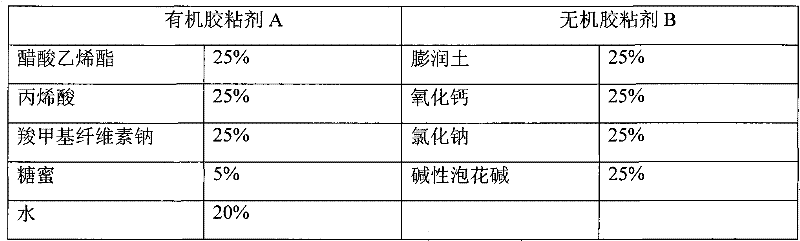

[0033] Composite adhesive formula is as follows: (calculated by weight fraction)

[0034]

[0035] Add vinyl acetate, acrylic acid, and sodium carboxymethyl cellulose into the four-neck bottle according to the proportion, then add water according to the proportion, stir at 90°C and 1500 rpm until the glue is evenly mixed, and then mix the glue Pour out the solution and cool it to room temperature, and finally mix the cooled glue solution with molasses evenly according to the proportion to obtain the organic adhesive A. Take bentonite, calcium oxide, high-temperature cement, and alkaline sodium hydroxide according to the proportion, and mix them evenly to obtain inorganic adhesive B.

[0036] According to the proportion, the organic adhesive A and the inorganic adhesive B are compounded and stirred evenly (the compounding ratio is 1: 1), and then added in the mixture of iron concentrate powder and iron-containing sludge according to the proportioning (the mixing ratio is: co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com