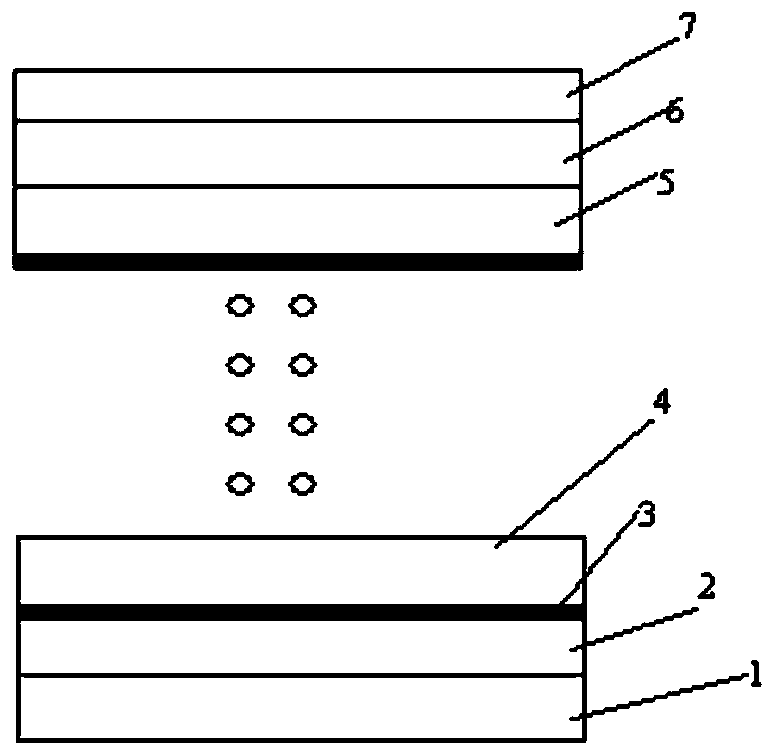

Shielding film with multilayer metal structure

A multi-layer metal and shielding film technology, applied in the direction of metal layered products, magnetic/electric field shielding, coating, etc., can solve the problem that copper foil and aluminum foil cannot meet the thickness and bending resistance, ordinary shielding film cannot meet the shielding performance requirements, no Use value etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

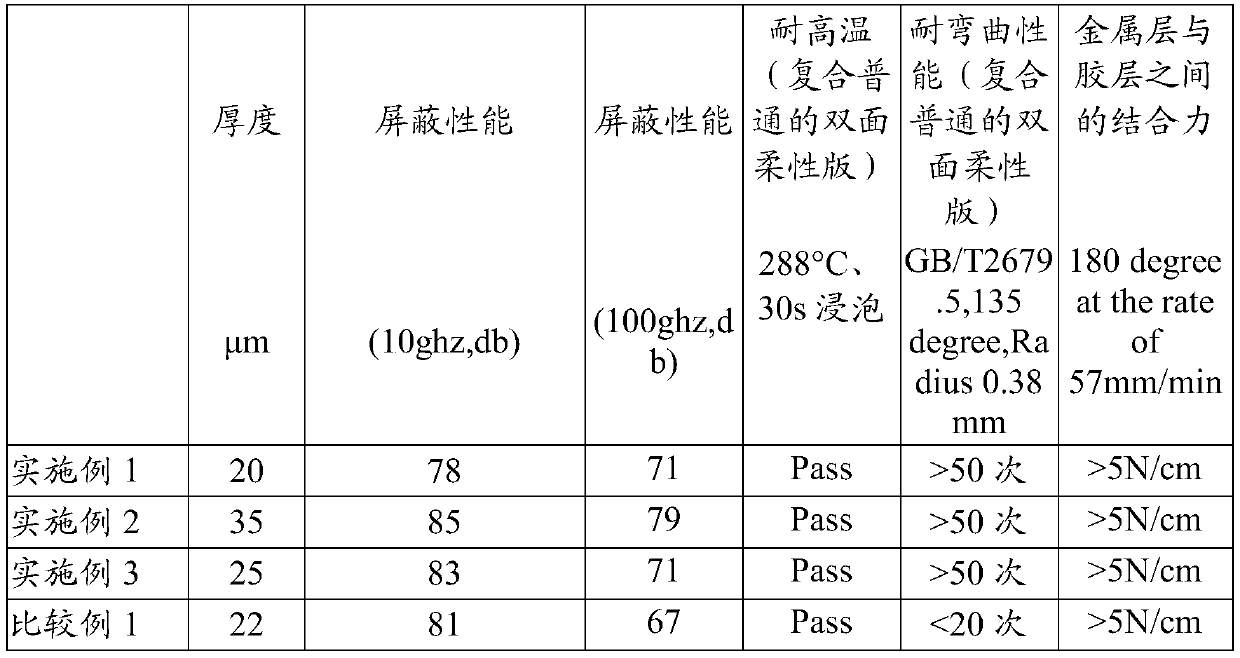

Embodiment 1

[0047] 1) Polyurethane insulating layer formula (according to 100 parts by weight):

[0048] Ren Chi 891 (Guangdong Pusaida Sealing Adhesive Co., Ltd.): 70

[0049] Titanium dioxide: 20

[0050] Auxiliary (Ren Chi 891 curing agent): 5

[0051] Color paste: black: 5

[0052] Ren Chi 891. Titanium dioxide, additives, and black color paste are mixed to obtain black ink;

[0053] 2) Coating black glue on the raw material film: Unwind the prepared release film on the coating line and pass through the coating head, and evenly coat a layer of black glue with a thickness of 3 μm. Solvent touch dry, good volume.

[0054] 3) Vacuum plating of 0.3μm silver layer;

[0055] 4) Apply a conductive adhesive layer with a thickness of 3 μm; the conductive adhesive layer includes epoxy glue, nickel powder, polyurethane curing agent and auxiliary agent with a mass ratio of 70:10:10:10, and is dried and cured;

[0056] 5) Plating a layer of 0.3 μm second metal nickel on the rubber surf...

Embodiment 2

[0060] 1) Formula of epoxy insulating layer (according to 100 parts by weight):

[0061] ZY-3600R (Zhongshan Zhuyi Electronic Materials Co., Ltd.): 70;

[0062] Tysun Universal Oily Black Paste (Dongguan Tysun Pigment Co., Ltd.): 10;

[0063] Titanium dioxide: 10;

[0064] ZY-3600R curing agent: 10;

[0065] Mix ZY-3600R, Tysun universal oily black paste, titanium dioxide and curing agent to get black glue;

[0066] Unwind the prepared release film on the coating line and pass through the coating head, evenly coat a layer of black glue with a thickness of 5 μm, dry the solvent surface in an oven at 100°C to 200°C, and wind up;

[0067] 3) Vacuum coating with 0.5μm copper;

[0068] 4) Apply a conductive adhesive layer with a thickness of 5 μm; the conductive adhesive layer includes epoxy glue, nickel powder, polyurethane curing agent and auxiliary agent with a mass ratio of 70:10:10:10, and is dried and cured;

[0069] 5) Plating a layer of 0.2 μm second metal silver on th...

Embodiment 3

[0074] 1) Formula adjustment of acrylic ink insulating layer (according to 100 parts by weight):

[0075] Petpur adhesive (Chongqing Luchuan): 70

[0076] Titanium dioxide: 10

[0077] petpur curing agent: 10;

[0078] Tysun Universal Oily Black Paste (Dongguan Tysun Pigment Co., Ltd.): 10;

[0079] Mix petpur adhesive, titanium dioxide, petpur glue curing agent and black color paste to obtain black glue;

[0080] 2) Coating black glue on the raw material film: Unwind the prepared release film on the coating line and pass through the coating head, and evenly coat a layer of black glue with a thickness of 7 μm. dry, roll;

[0081] 3) Vacuum plating of 1 μm copper layer;

[0082] 4) Apply a conductive adhesive layer with a thickness of 8 μm; the conductive adhesive layer includes epoxy glue, nickel powder, polyurethane curing agent and auxiliary agent with a mass ratio of 70:10:10:10, and is dried and cured;

[0083] 5) Plating a layer of 0.5 μm second metal copper on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com