Compound bacterial agent and its application

A technology of compound bacterial agent and preparation, applied in the direction of application, urea compound fertilizer, bacteria, etc., can solve the problems that need to be studied, and achieve the effect of increasing the weight loss rate of straw, reducing C/N content, and good composting effect of straw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Strain isolation and screening

[0030] (1) Isolation of cellulase-producing strains: collect rotten straw and livestock manure in the test field of Sinochem Agriculture Linyi R&D Center, weigh 1g into 100ml sterile water, shake at 150rpm, 30°C for 30min, and then carry out gradient diluted to 10 5 , select 3 gradients for coating, and each gradient has 3 parallels. After culturing in a 30°C incubator for 2 days, select strains with different colony forms to streak on LB medium, and observe the growth of colonies regularly. Then, the plate streak method was used to purify the strains, and they were numbered and stored separately.

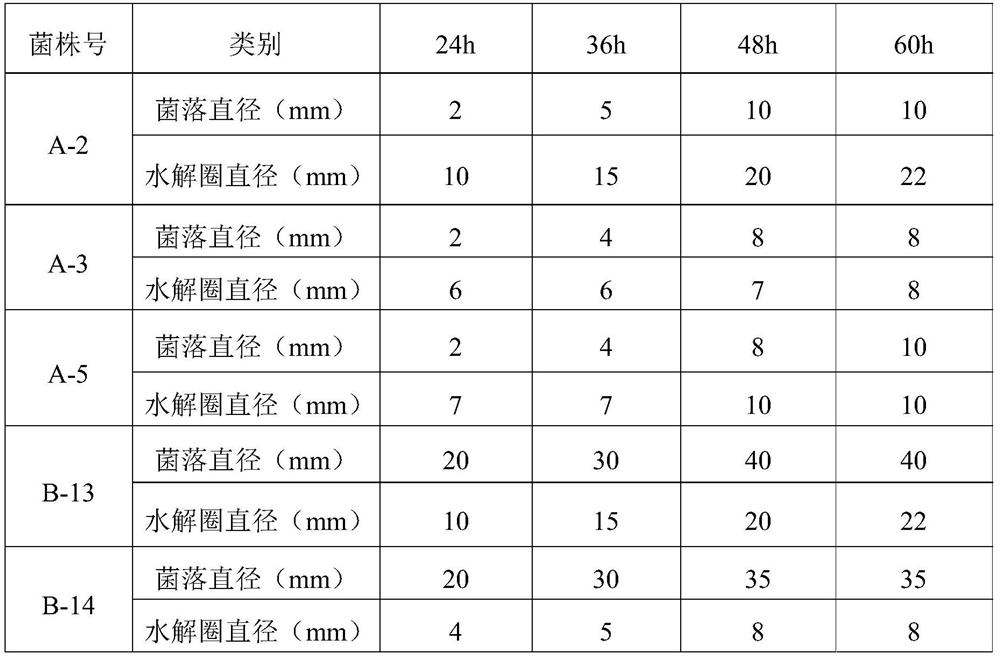

[0031] (2) Screening of cellulase-producing strains: Prepare LB medium (adding sodium carboxymethyl cellulose) by plate hydrolysis circle method, transplant the strains isolated and preserved in (1) into the center of the plate with a toothpick, and keep at 30°C After incubating at constant temperature for 48 hours, absorb 5ml of 2‰ Cong...

Embodiment 2

[0046] 1. Identification of strain A-2

[0047] (1) Microbiological characteristics: Cultured on LB medium at 37°C for 2 days to form colonies with a size of about 4 mm, neat edges, raised, white viscous and translucent. The optimum growth temperature is 37°C, the salt tolerance (NaCl) concentration is 14%, the growth pH is 4.0-9.0, and the optimum is 7.0.

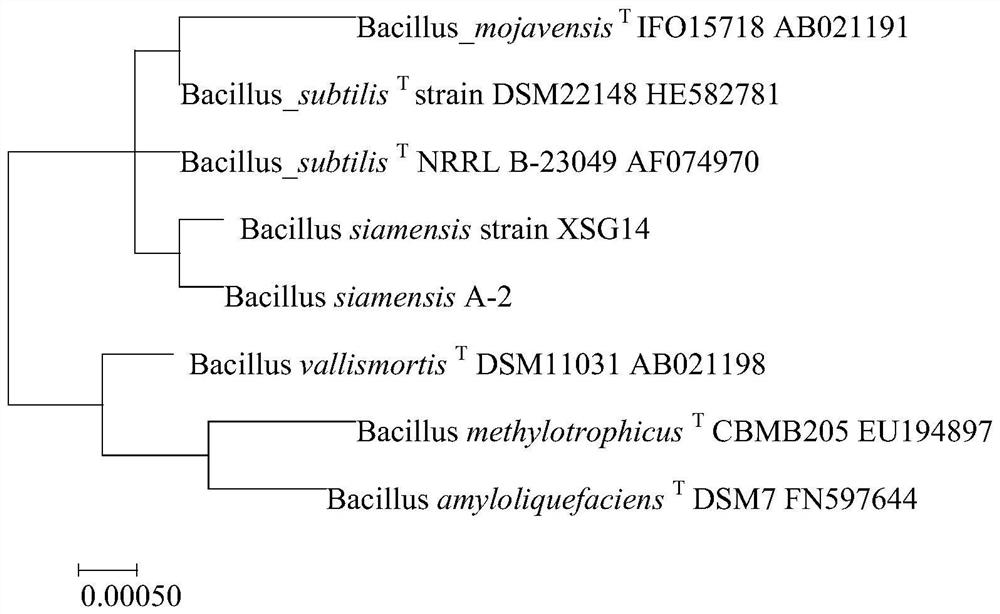

[0048] (2) Molecular biological characteristics: The phylogenetic tree of the strain formed by the 16SrDNA sequence of molecular biology showed that the strain had the closest homology to Bacillus siamensis strain XSG14. The strain was Bacillus siamensis.

[0049] The 16SrDNA sequence of the strain is as follows, and the phylogenetic tree can be found in figure 1 .

[0050] TCTCGTGGTGTGACGGGCGGTGTGTACAAGGCCCGGGAACGTATTCACCGCGGCATG CTGATCCGCGATTACTAGCGATTCCAGCTTCACGCAGTCGAGTTGCAGACTGCGATCC GAACTGAGAACAGATTTGTGGGATTGGCTTAACCTCGCGGTTTCGCTGCCCTTTGTTC TGTCCATTGTAGCACGTGTGTAGCCCAGGTCATAAGGGGCATGATGATTTGACGTCATC CCCACCTTCCTCCG...

Embodiment 3

[0056] The preparation of embodiment 3 microbial bacterial agents

[0057] 1. Preparation of Bacillus siamese preparation

[0058] Step 1: Inoculate the Bacillus siamese strain A-2 preserved in the plate into an Erlenmeyer flask containing 250ml of LB culture solution with an inoculation loop, and culture it in a constant temperature incubator at 30°C and 170rpm for 36h.

[0059] Step 2: Inoculate the above-mentioned fermented bacteria liquid into a pilot test fermenter (10L-50L-500L), cultivate at 37°C, spray dry after the fermentation is completed, and subpackage. The number of viable bacteria is 10-15 billion / g. Mix it with calcium carbonate to form a bacterial powder with a viable count of 10 billion / g, which is to prepare the Bacillus siamese A-2 bacterial agent for composting. The formula of pilot test medium is: corn starch 3%, sucrose 1%, soybean meal 4.5%, yeast powder 0.2%, peptone 0.2%, dipotassium hydrogen phosphate, potassium dihydrogen phosphate 0.3%, calcium ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com