Sodium-modified chemical-looping hydrogen production synergistic CO2 trapping system

A chemical chain, CO2 technology, applied in the direction of inorganic chemistry, bulk chemical production, chemical instruments and methods, etc., can solve the problems of corrosion equipment, easy deactivation, etc., to avoid carbon deposition, fast reaction speed, save operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

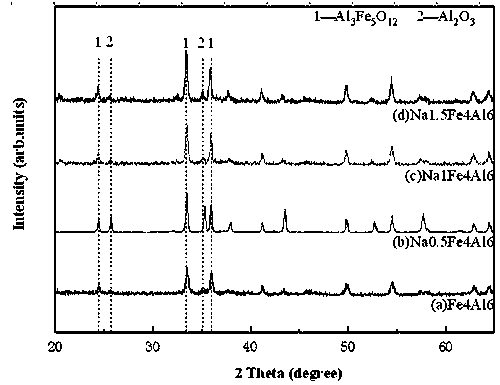

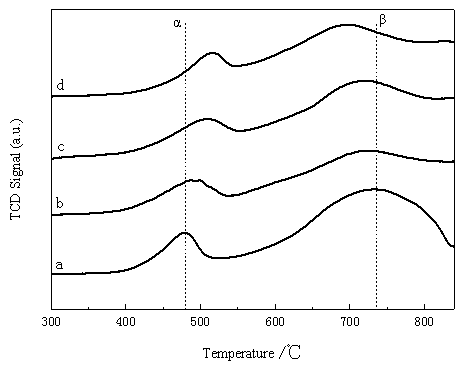

[0027] Press Fe 2 o 3 :Al 2 o 3 The mass ratio is 4:16, weigh Fe(NO 3 ) 3 •9H 2 O, γ-Al2O3, without adding NaAlO2, Fe(NO 3 ) 3 •9H 2 O was impregnated into γ-Al2O3, stirred on a magnetic stirrer at 90°C for 2h, dried in a drying oven at 120°C for 12h, and moved into a muffle furnace for calcination at 900°C for 3h. The product is recorded as Fe4Al6.

Embodiment 2

[0029] by NaAlO 2 :Fe 2 o 3 :Al 2 o 3 The mass ratio is 0.5:4:6, weigh Fe(NO3)3•9H 2 O, γ-Al 2 o 3 , NaAlO 2 , the NaAlO 2 and Fe(NO 3 ) 3 •9H 2 O impregnation into γ-Al 2 o 3 , stirred on a magnetic stirrer at 90°C for 2h, dried in a drying oven at 120°C for 12h, and moved into a muffle furnace for calcination at 900°C for 3h. The product is recorded as Na0.5Fe4Al6.

Embodiment 3

[0031] by NaAlO 2 :Fe 2 o 3 :Al 2 o 3 The mass ratio is 1:4:16, weigh Fe(NO3)3•9H 2 O, γ-Al 2 o 3 , NaAlO 2 , the NaAlO 2 and Fe(NO3)3•9H 2 O impregnation into γ-Al 2 o 3 , stirred on a magnetic stirrer at 90°C for 2h, dried in a drying oven at 120°C for 12h, and moved into a muffle furnace for calcination at 900°C for 3h. The product is recorded as Na1Fe4Al6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com