Scraper device and photo-curing equipment with scraper device

A scraper device, scraper technology, applied in metal processing equipment, manufacturing tools, additive manufacturing, etc., can solve the problems of difficult to eliminate bubbles, prolonged process time, poor printing effect, etc., to achieve the improvement effect and reduce the generation of bubbles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

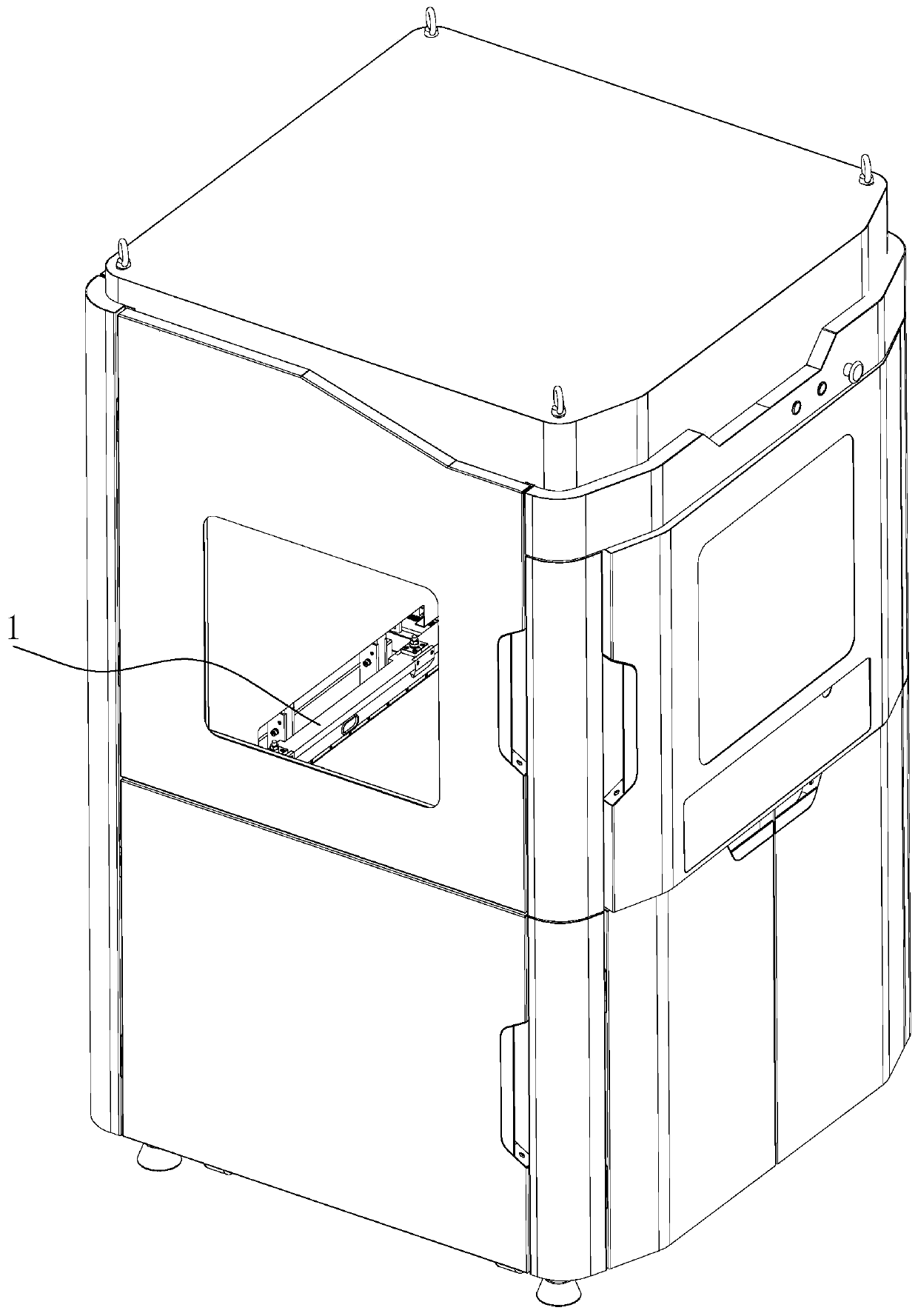

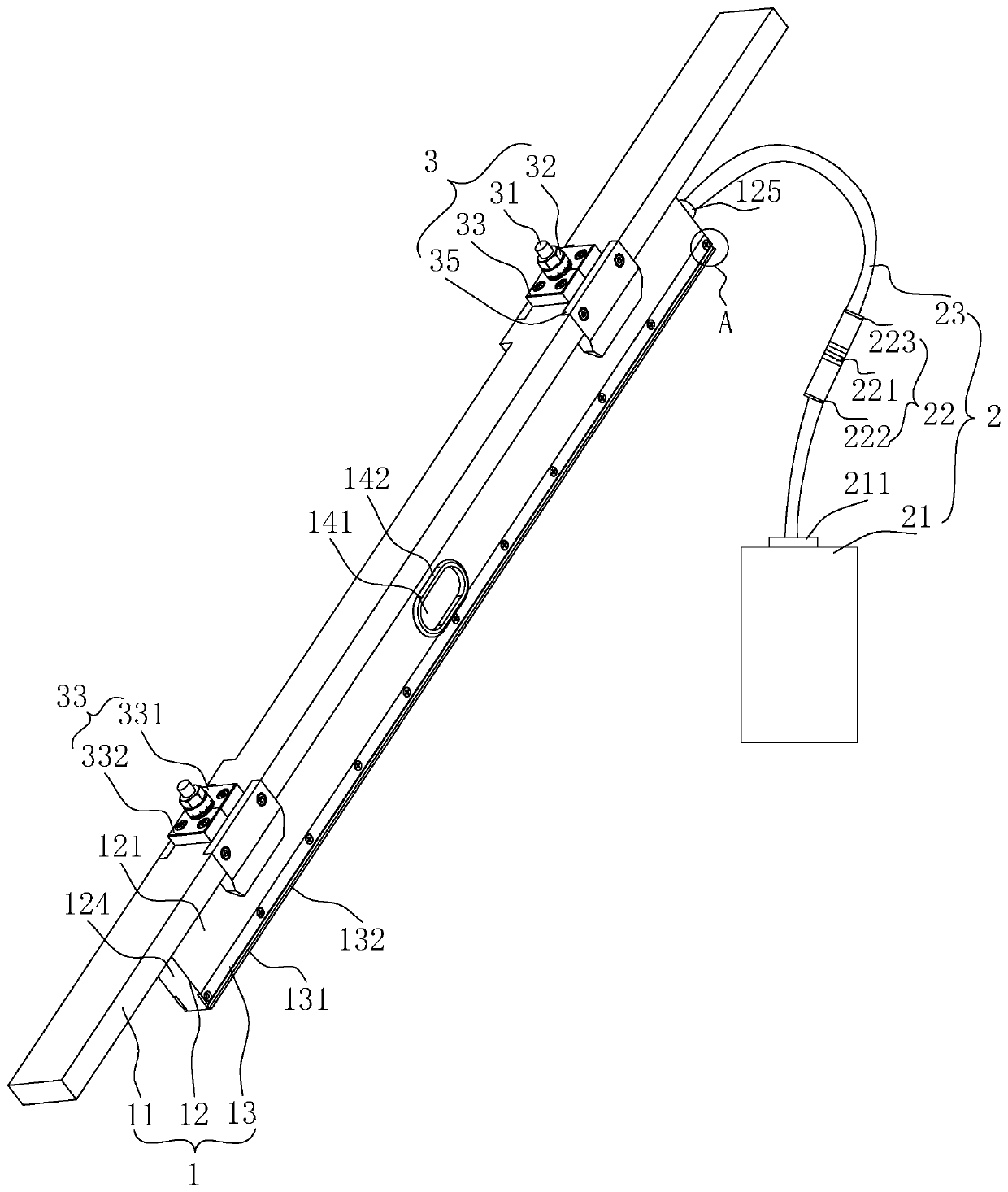

[0050] refer to figure 1 , figure 2 , a scraper device and photocuring equipment provided by the present invention include a scraper body 1 and an air extraction device 2 .

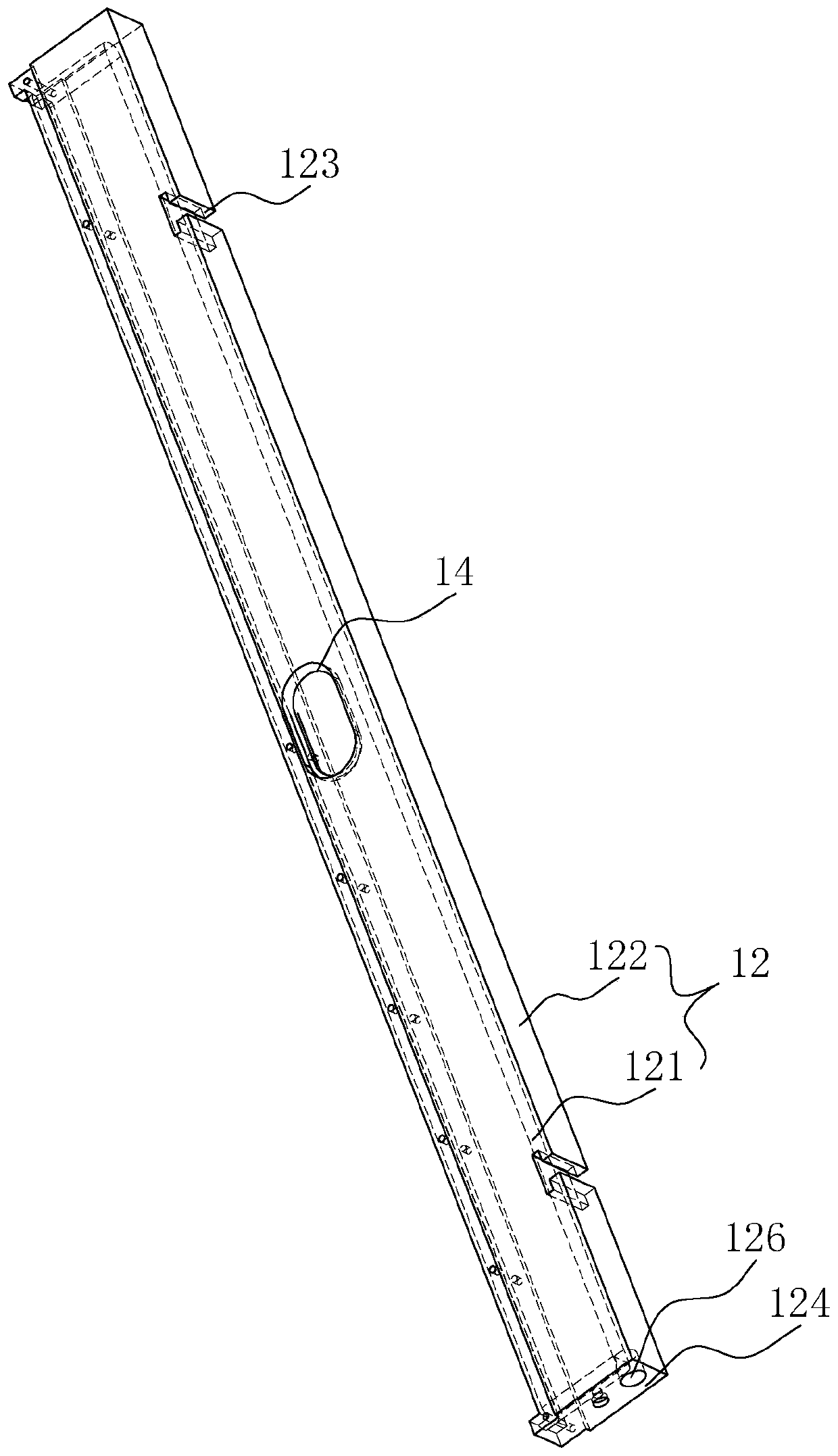

[0051] The above-mentioned scraper body 1 includes a knife holder 11 , a knife body 12 and a lower edge 13 of the scraper for leveling the liquid surface. Wherein the clip between the knife rest 11, the knife body 12 and the lower edge 13 of the scraper is detachable and assembled. Further, the knife holder 11, the knife body 12 and the lower edge 13 of the scraper can be made of aluminum alloy, stainless steel, plastic and other materials.

[0052] refer to figure 2 , image 3 , the blade body 12 includes a blade back 122 and a blade side 121, the blade side 121 is integrally connected with both sides of the blade back 122, and the two blade sides 121 are arranged parallel to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com