Reusable bacteria-haze-virus prevention mask and preparation method thereof

An anti-virus and mask technology, applied in the field of masks, can solve the problems of waste of resources, single means and high cost, and achieve the effects of preventing external droplets and liquid splashing, skin-friendly and comfortable tightness, and reducing the cost of combined use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

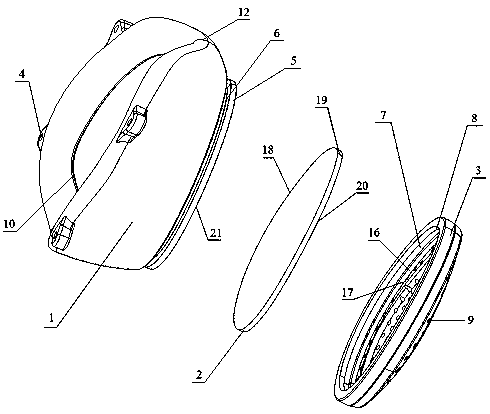

[0049] The outer layer and inner layer of the barrier filter are made of polypropylene spunbonded non-woven fabric, which is pre-paved, baked, loaded with composite catalytic catalyst material and made of water-repellent finishing;

[0050] The middle layer uses a layer of melt-blown polypropylene non-woven fabric treated with electrostatic electret, a layer of activated carbon felt and a layer of hygroscopic spunlace non-woven fabric. Catalytic catalyst material.

[0051] The outer layer of polypropylene spunbond non-woven fabric, melt-blown polypropylene non-woven fabric, carbon felt, spunlace non-woven fabric and inner layer of polypropylene spunbond non-woven fabric are stacked together in sequence, and the ultrasonic non-woven fabric is used for spot welding Machine spot welded into one piece, or glued or sewn into one piece. According to the inner size and shape of the inner surface 16 of the groove ring in the middle of the cover, the matching barrier filter is cut.

...

Embodiment 2

[0054] The outer layer and inner layer of the barrier filter are made of polypropylene spunbonded non-woven fabric, which is pre-padded, baked, loaded with commercially available antibacterial agents, and water-repellent finishing; the middle layer is made of 3 layers of melt blown with electrostatic electret treatment Polypropylene nonwoven.

[0055] The outer layer of polypropylene spunbond non-woven fabric, three layers of melt-blown polypropylene non-woven fabric and the inner layer of polypropylene spunbonded non-woven fabric are stacked together in sequence, and are welded together by ultrasonic non-woven fabric spot welding machine, or use Glued or sewn into one piece. According to the inner size and shape of the inner surface 16 of the groove ring in the middle of the cover, the matching barrier filter is cut.

[0056] Put the barrier filter flat in the groove ring in the middle of the face cover, the outer layer 20 of the barrier filter is in close contact with the i...

Embodiment 3

[0058] The outer layer and inner layer of the barrier filter are made of polypropylene spunbonded non-woven fabrics, which are pre-padded, baked, loaded with composite catalytic catalyst materials and treated for water repellency; the middle layer is made of 1 layer of polytetrafluoroethylene PTFE nano-film.

[0059] The outer layer of polypropylene spun-bonded non-woven fabric, one layer of polytetrafluoroethylene PTFE nano-film, and the inner layer of polypropylene spun-bonded non-woven fabric are stacked together in sequence, and are welded together by ultrasonic non-woven spot welding machine, or use Glued into one. According to the size and shape of the outer diameter and shape of the reinforcing rib convex snap ring 5 equal to or slightly larger than the front opening of the cover body, a matching barrier filter is cut.

[0060] Put the inner layer 18 of the barrier filter in close contact with the outer plane 21 of the rib convex ring of the front opening of the cover b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com