Mask production process and device for implementing process

A production process and mask technology, which is applied in the field of masks, can solve the problems of low production efficiency, poor connection firmness of the hanging ears, and inconvenient production, and achieve the effects of high production efficiency, fast production process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will now be further described with reference to the drawings and specific embodiments.

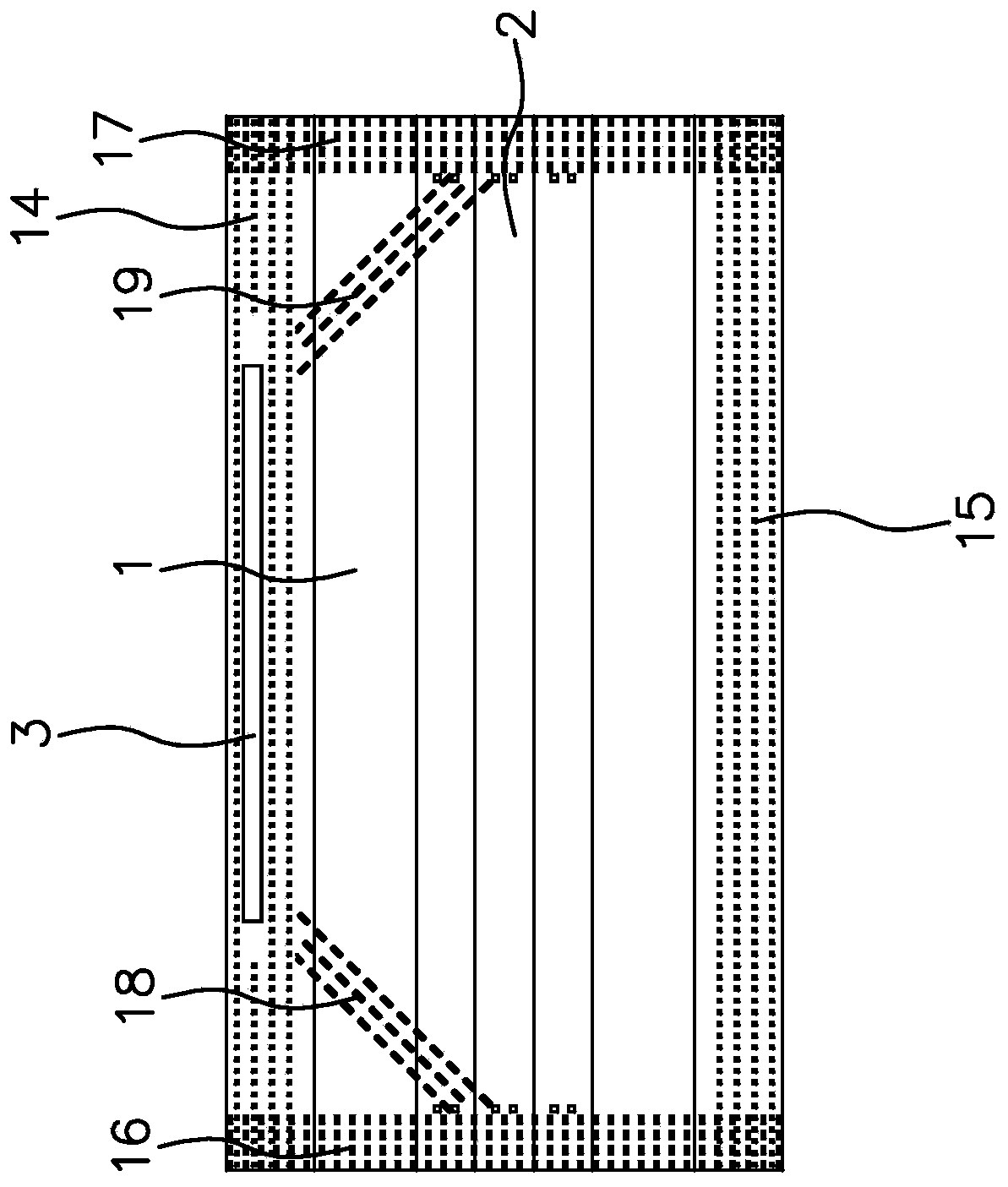

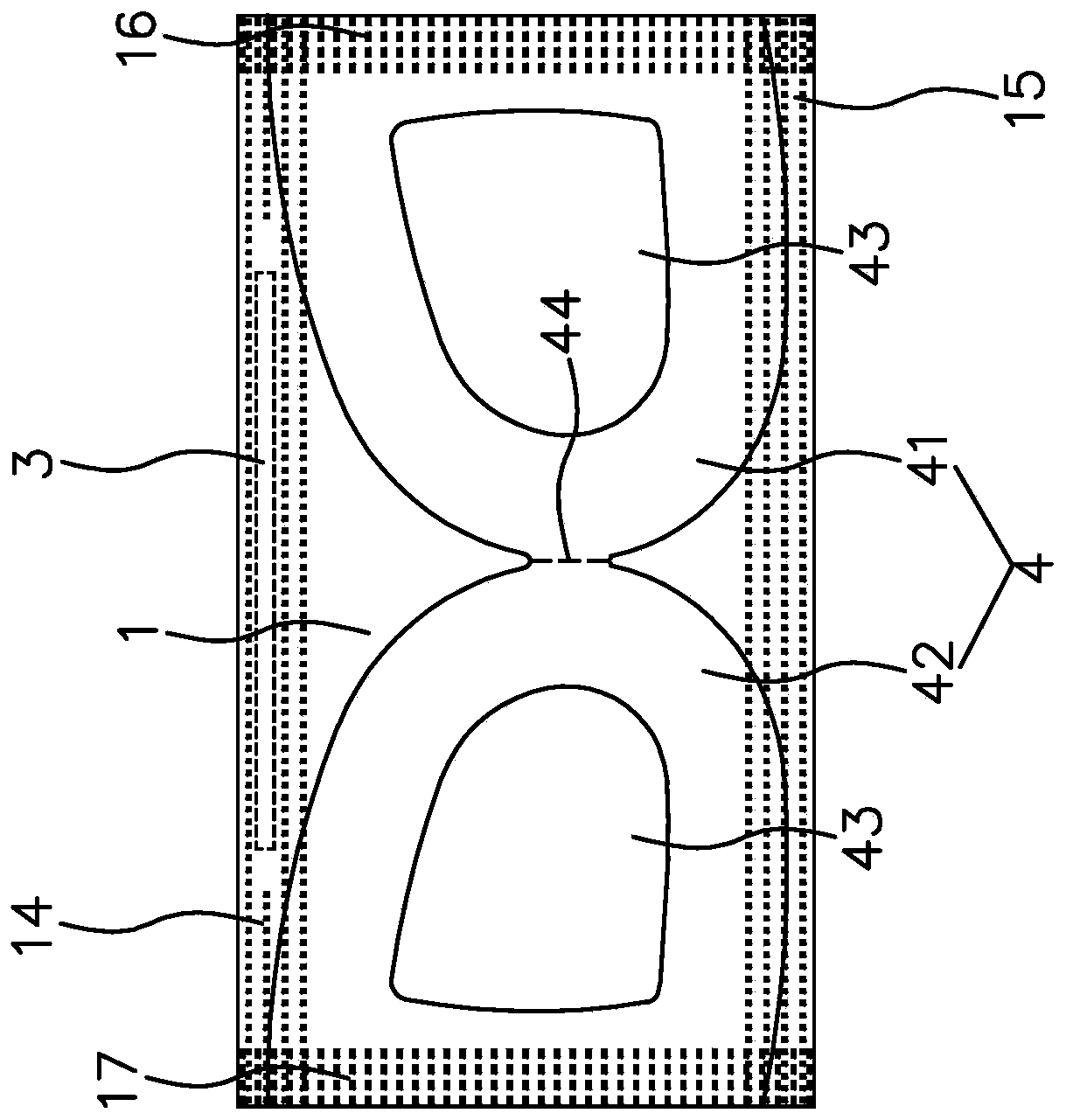

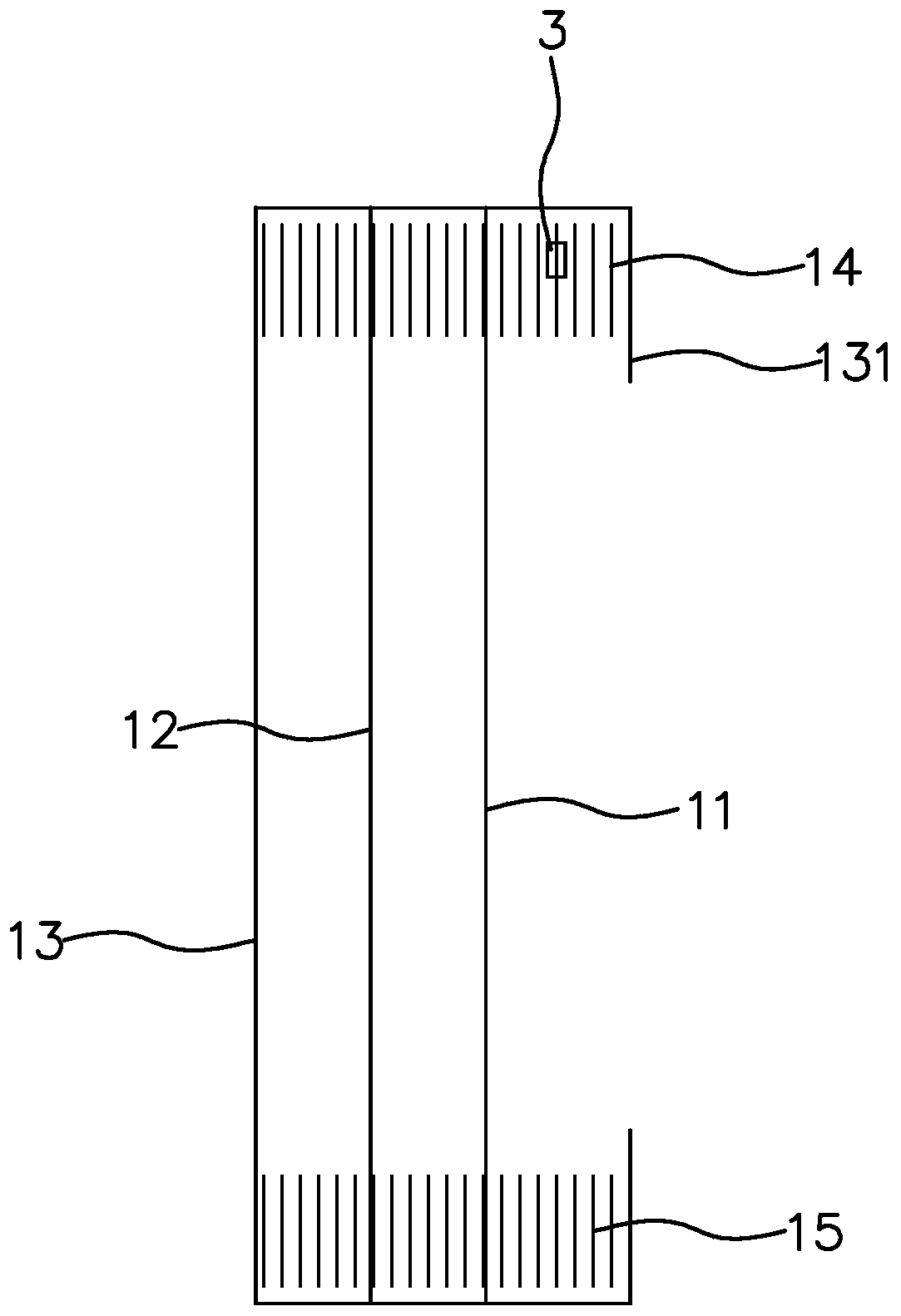

[0049] This embodiment provides a mask, reference Figure 1 to Figure 5 , Including a mask body 1, the mask body 1 is provided with a crimping portion 2 in the middle of the longitudinal direction, the crimping portion 2 is formed by stacking three crimping 21, the mask body 1 includes an outer filter layer 11, an intermediate filter Layer 12, inner filter layer 13, the middle filter layer 12 is ultra-fine polypropylene fiber non-woven fabric, the outer filter layer 11, the inner filter layer 13 are spunbonded non-woven fabric, the inner filter layer 13 along The length in the longitudinal direction is greater than the middle filter layer 12 and the outer filter layer 13. The upper and lower sides of the inner filter layer 13 are wrapped on the outer surface of the outer filter layer 11 to form a folded portion 131. The upper side, lower side, left side, and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com