Platinum-carbon catalyst and preparation method and application thereof

A technology of platinum-carbon catalyst and carbon powder, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of platinum falling off and not solving the problem of reverse pole, and achieve the problem of solving the problem of reverse pole, improving the carrier shedding rate, and consistent batches good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

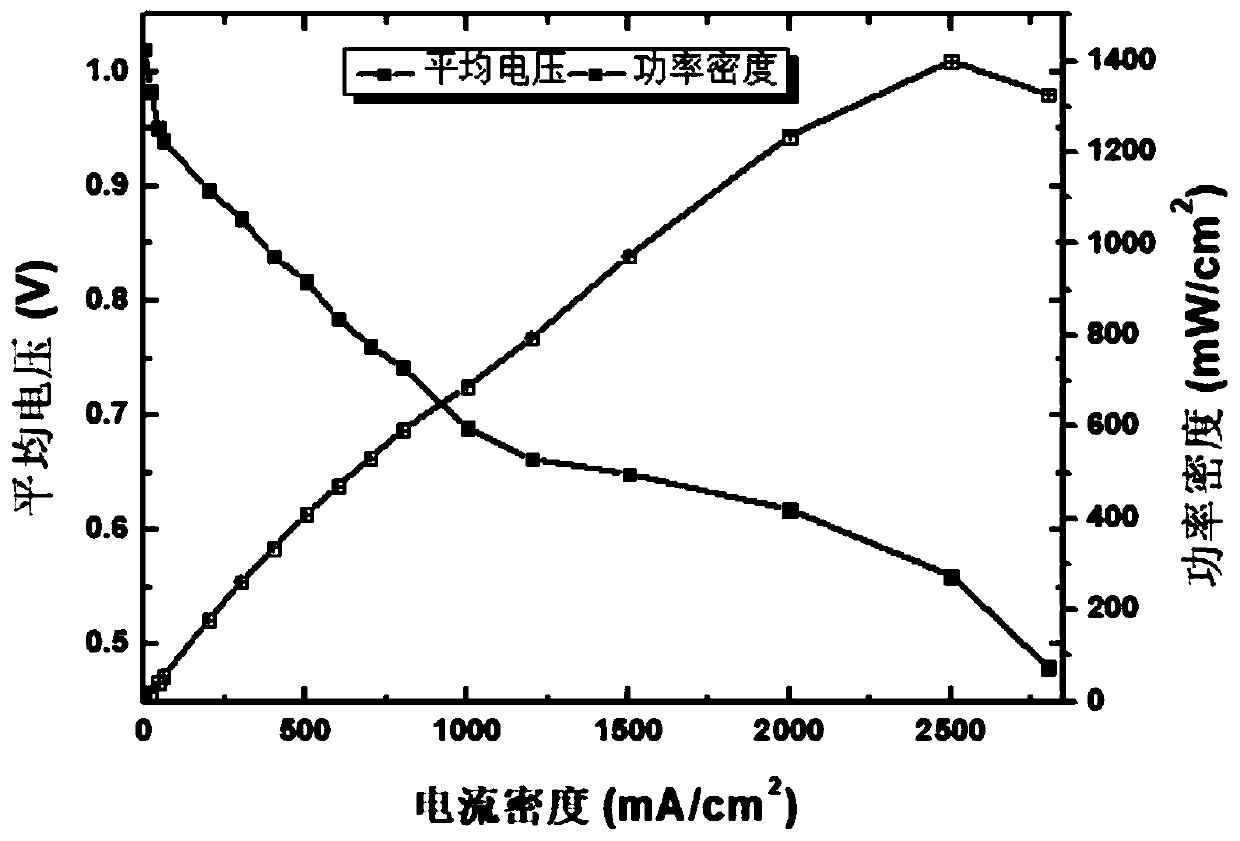

Image

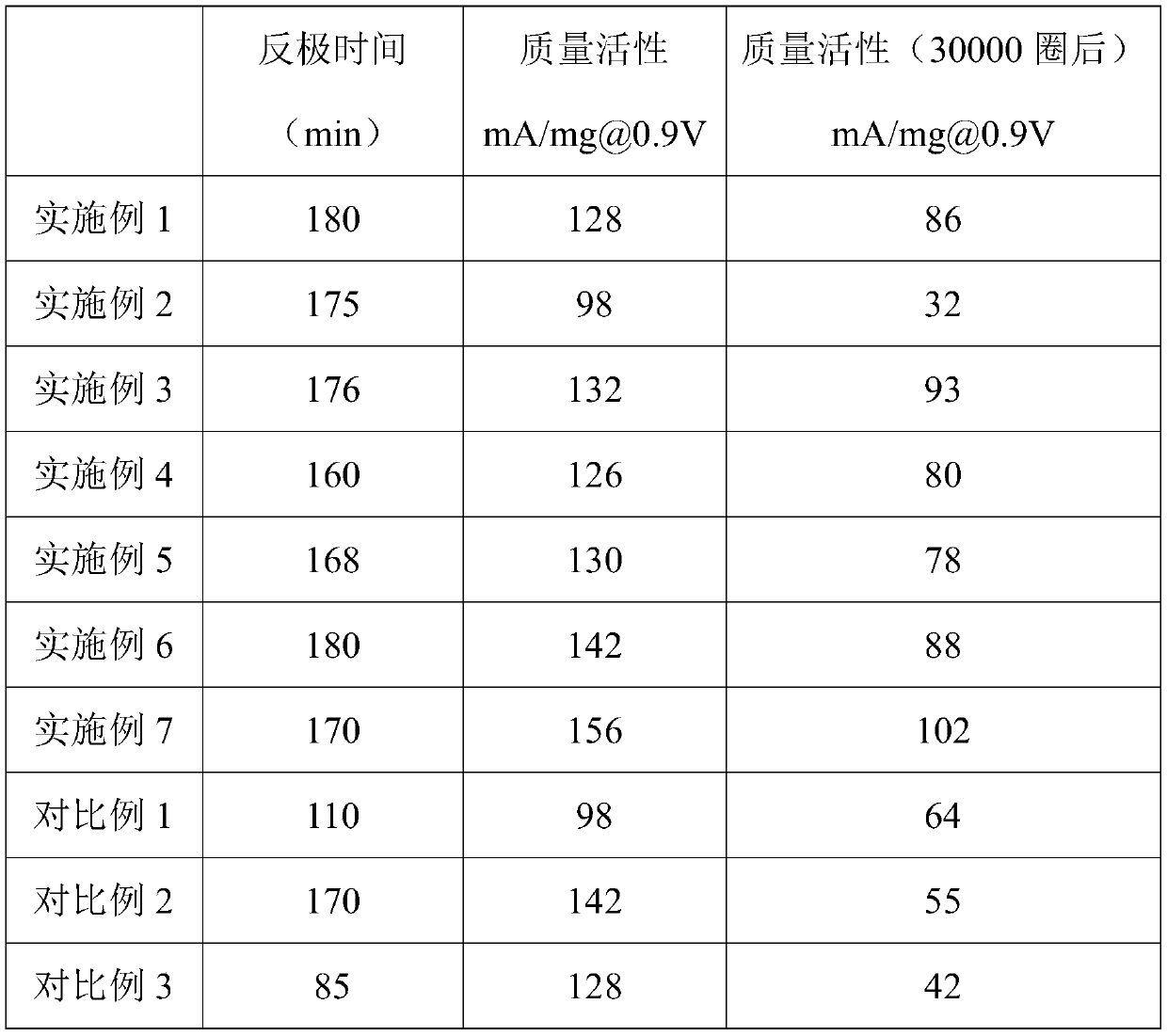

Examples

Embodiment 1

[0063] The present embodiment provides a kind of preparation method of platinum carbon catalyst, comprises the following steps:

[0064] (1) 5g of graphene is placed in 100mL of nitric acid solution with a mass fraction of 40%, reflux at 60°C, magnetically stirred for 4h, the sample is suction filtered, washed until the pH is 4, and vacuum-dried at 80°C to obtain toner;

[0065] (2) Put the carbon powder in 100ml of 30% hydrogen peroxide solution by mass fraction, stir for 2 hours, perform suction filtration, wash until neutral, and dry in vacuum at 100°C to obtain the carbon carrier;

[0066] (3) Take 0.2 g of the carbon carrier obtained in step (2) and place it in 50 mL of chloroplatinic acid solution containing platinum at a concentration of 0.006 g / mL. After ultrasonication for 5 min, add 8 g of isopropanol for emulsification and shearing for 5 min, and add 1.23 g 50ml of 0.1mg / ml sodium formate solution of ascorbic acid, 20g of 0.05wt% graphene dispersion of 0.1wt% ammon...

Embodiment 2

[0074] The present embodiment provides a kind of preparation method of platinum carbon catalyst, comprises the following steps:

[0075] (1) Place 5 g of carbon nanospheres in 100 mL of nitric acid solution with a mass fraction of 56%, reflux at 80 ° C, and magnetically stir for 6 h, filter the sample, wash it to pH 6, and dry it at 60 ° C to obtain toner;

[0076] (2) Put the carbon powder in 134ml of 30% hydrogen peroxide solution and stir for 4h, perform suction filtration, wash to neutrality, and dry at 100°C to obtain the carbon carrier;

[0077](3) Take 0.2 g of the carbon carrier obtained in step (2) and place it in 25 mL of chloroplatinic acid solution containing platinum at a concentration of 0.006 g / mL. After ultrasonication for 10 min, add 14.8 g of n-butanol for emulsification and shearing for 10 min. Add 0.38 20ml of 0.1mg / ml sodium formate solution of g ascorbic acid, 20g of 0.01wt% graphene dispersion of 0.3%wt ammonium carbamate, under the protection of helium...

Embodiment 3

[0079] The present embodiment provides a kind of preparation method of platinum carbon catalyst, comprises the following steps:

[0080] (1) Put 5g of Vulcan XC-72 in 80mL of nitric acid solution with a mass fraction of 42%, reflux at 80°C and magnetically stir for 4h, filter the sample, wash to pH 6, and dry at 70°C. get toner;

[0081] (2) Put the carbon powder in 120ml of 30% hydrogen peroxide solution and stir for 4 hours, perform suction filtration, wash to neutrality, and dry at 100°C to obtain the carbon carrier;

[0082] (3) Take 0.2 g of the carbon support obtained in step (2) and place it in 25 mL of platinum nitrate solution with a platinum concentration of 0.006 g / mL. After ultrasonication for 10 min, add a mixture of 8 g of n-butanol and 6 g of isopropanol to carry out Emulsified and sheared for 8min, added 30ml of 0.1mg / ml sodium formate solution of 1.05g ascorbic acid, 20ml of 0.05wt% graphene dispersion of 0.2wt% ammonium carbamate, under argon protection, ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com