Dynamic optimization control method for temperature of heating furnace based on combustion-supporting air flow calculation

A combustion-supporting air and flow calculation technology, applied to furnace control devices, heat treatment furnaces, lighting and heating equipment, etc., can solve unseen problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

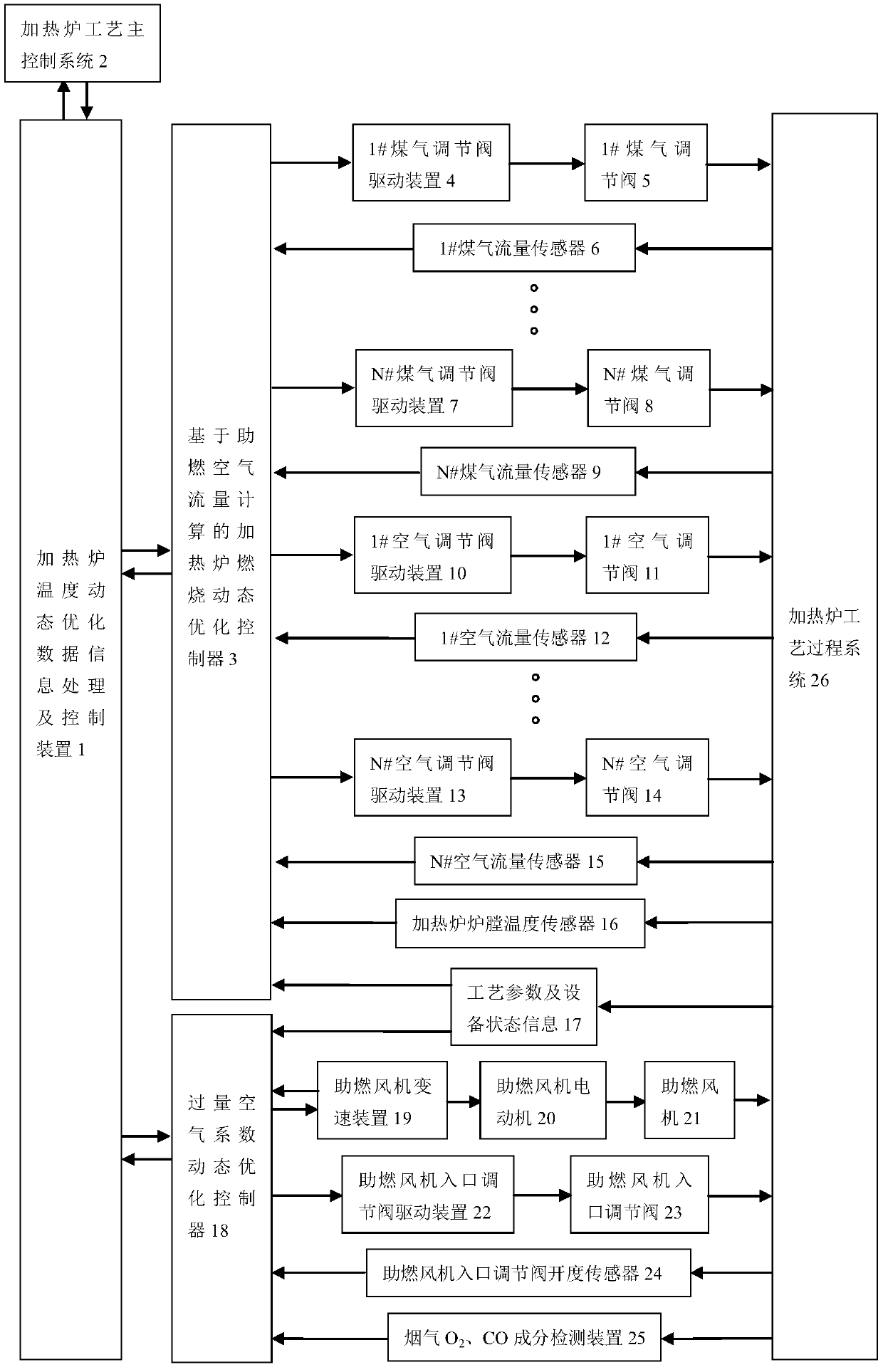

[0013] The system of the heating furnace temperature dynamic optimization control method based on the combustion air flow calculation is composed of two control units, one control unit is the heating furnace combustion dynamic optimization controller based on the combustion air flow calculation, and the other control unit is the dynamic optimization of the excess air coefficient Controller: Control the output flow of the air control valve according to the calculation of the combustion air flow, so that it can accurately match the flow of the gas control valve according to the given air-fuel ratio, which can obtain a good combustion effect, save gas consumption, and improve the thermal efficiency of the heating furnace ; Under the premise of obtaining a good combustion effect, according to the detected O in the flue gas 2 , CO composition, adopt the method of adjusting the speed of the combustion-supporting fan to dynamically control the excess air coefficient, so that the excess ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com