Construction method for upper and lower layer vertical connection of fabricated steel-concrete combined pipes

A construction method and a technology of combined pipes, which are applied in construction, building structure, and building material processing, can solve problems affecting stability, affecting the efficiency of tower cranes and project progress, and occupying a large amount of cranes, so as to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

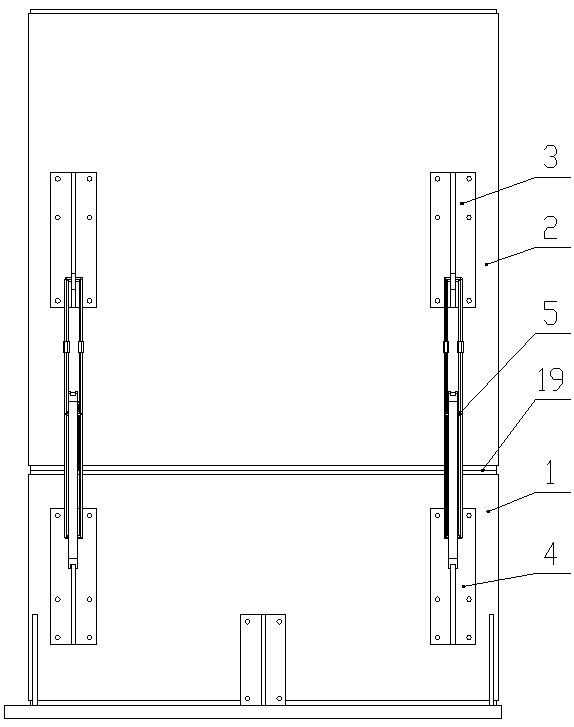

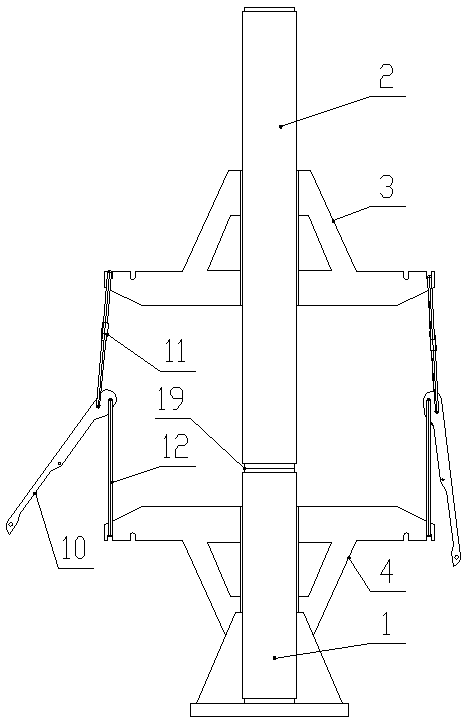

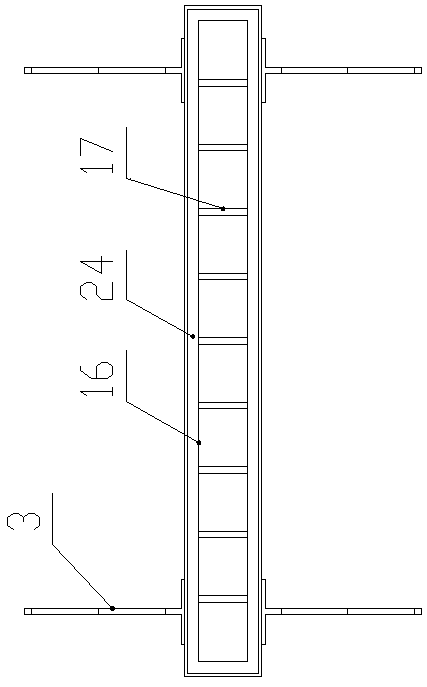

[0040] Embodiment one: if Figure 1-Figure 7 As shown, the vertical connection construction method of the upper and lower layers of the assembled steel-concrete composite pipe of the present invention comprises the following steps:

[0041] (1), install the temporary positioning device on the front side and the rear side of the upper steel-concrete composite pipe 2 and the lower steel-concrete composite pipe 1;

[0042] (2) Use a tower crane to hoist the upper layer of steel-concrete composite pipe 2 to the fixed lower layer of steel-concrete composite pipe 1 and basically correspond up and down;

[0043] (3) Operate the temporary positioning device so that the upper steel-concrete composite pipe 2 and the lower steel-concrete composite pipe 1 are fixedly connected as one, and the tower crane loosens the hoisted upper steel-concrete composite pipe 2 to hoist other fabricated components;

[0044] (4) Use tools to fine-tune the temporary positioning device until the vertical pl...

Embodiment 2

[0059] Embodiment two: if Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the upper tie rod assembly 11 includes an upper hanging ring 21, a lower hanging ring 22 and a turnbuckle 23, and the upper end of the upper hanging ring 21 is hooked on the upper part of the upper support plate 7. In the positioning groove 9, the upper end of the turnbuckle 23 is connected with the bottom of the upper hanging ring 21, the lower end of the lower hanging ring 22 is pierced and connected in the front pull hole, and the lower end of the turnbuckle 23 is connected with the top of the lower hanging ring 22.

[0060] Using tools to fine-tune the temporary positioning device in step (4) refers to rotating the turnbuckle 23 or the internally threaded sleeve 15 to adjust the length of the upper tie rod assembly 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com