Method for preparing gradient equiaxed crystals in zirconium alloys by laser surface treatment-rolling annealing composite process

A technology of laser surface treatment and composite technology, applied in the field of axial crystals, to achieve the effect of convenient operation, simple equipment, and enhanced bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

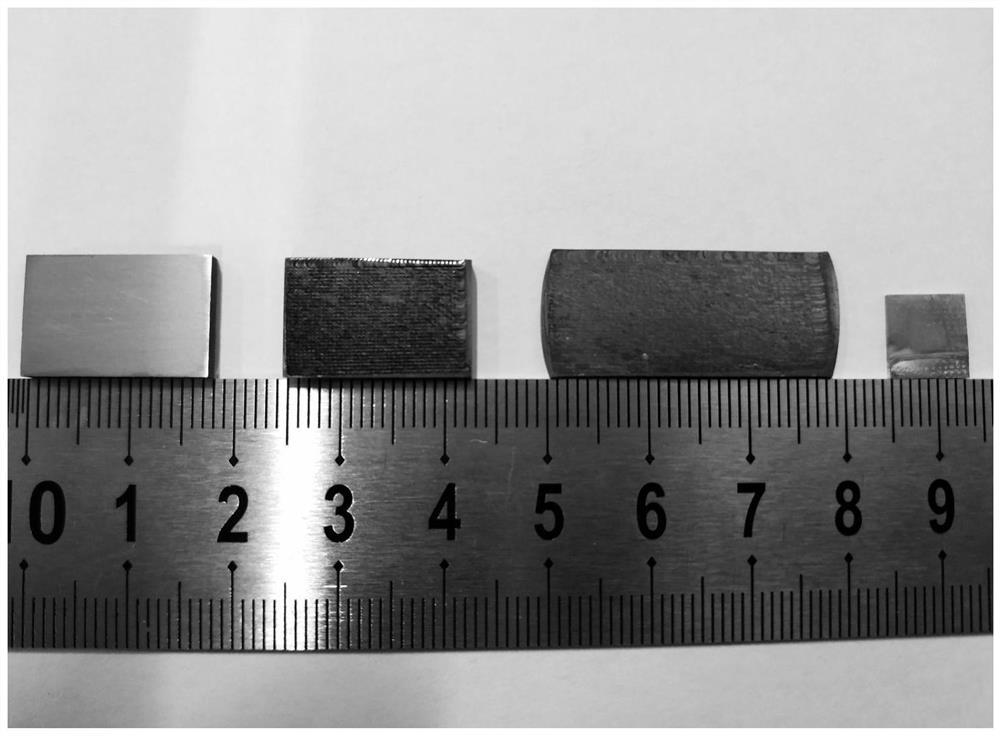

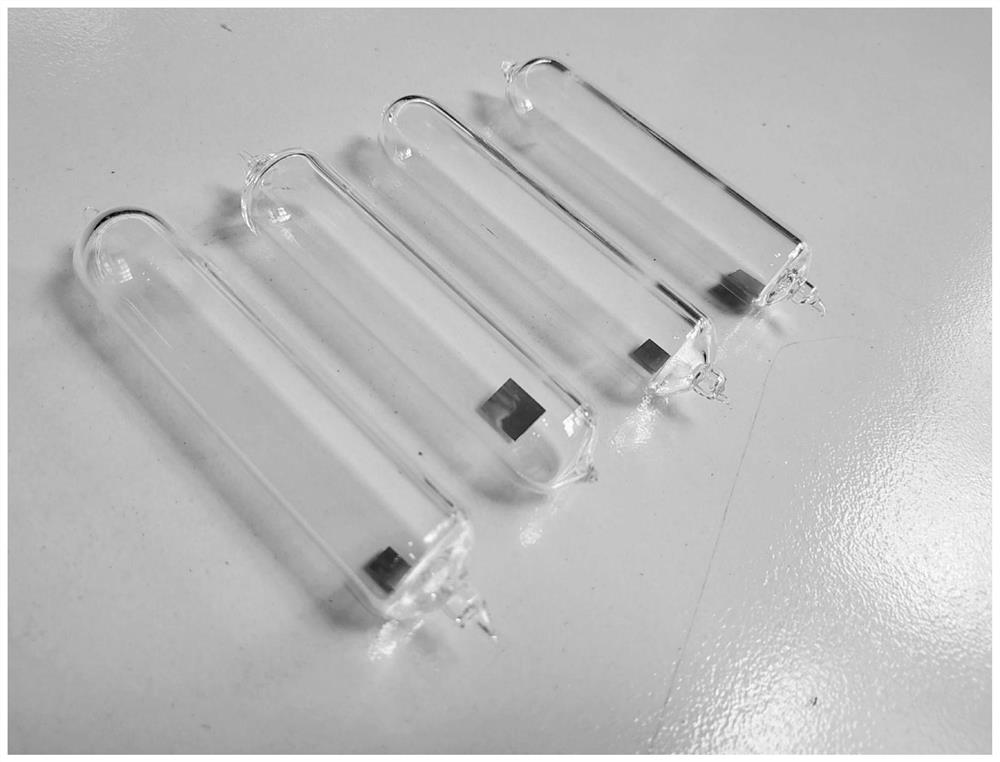

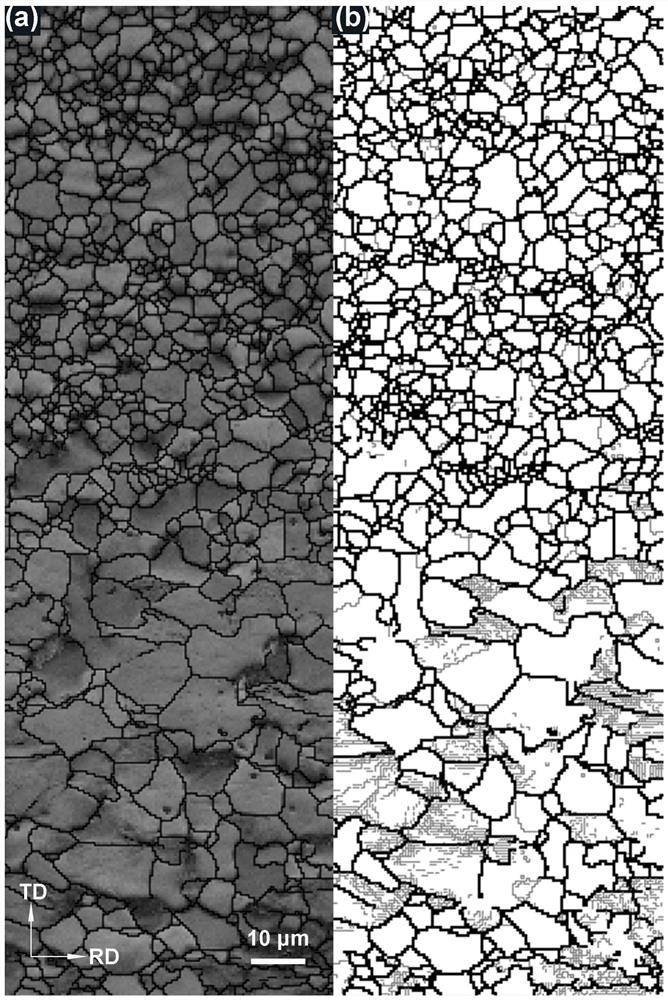

[0026] Select the prepared Zr702 sample of 18×12×2mm, first use 800#, 1000#, 1200#, 2000# and 3000# sandpaper to polish the sample until it is bright. After the sample was polished, it was cleaned with absolute ethanol, and finally its surface was dried. Then the sample was placed on the YAG laser workpiece table and fixed with iron clips. Then, the protective gas pipeline was fixed above the surface of the sample, and argon with a purity of 99.9% was used as the protective gas to ensure an argon atmosphere around the sample. Then set the laser parameters and set the laser beam path. Start the laser, load the voltage, turn on the argon gas, and perform laser surface treatment on the surface of the Zr702 sample. The process parameters of the laser surface treatment are: laser power 36W, scanning speed 6mm s -1 , defocus amount 0mm, peak value 1KW, pulse width 6m s, frequency 6HZ, power density 45.85W mm -2 , energy density 7.5W·s·mm -1 . Finally, take out the sample after ...

Embodiment 2

[0030]Select the prepared Zr702 sample of 18×12×2mm, first use 800#, 1000#, 1200#, 2000# and 3000# sandpaper to polish the sample until it is bright. After the sample was polished, it was cleaned with absolute ethanol, and finally its surface was dried. Then the sample was placed on the YAG laser workpiece table and fixed with iron clips. Then, the protective gas pipeline was fixed above the surface of the sample, and argon with a purity of 99.9% was used as the protective gas to ensure an argon atmosphere around the sample. Then set the laser parameters and set the laser beam path. Start the laser, load the voltage, turn on the argon gas, and perform laser surface treatment on the surface of the Zr702 material. The process parameters of the laser surface treatment are: laser power 36W, scanning speed 6mm s -1 , defocus amount 0mm, peak value 1KW, pulse width 6m s, frequency 6HZ, power density 45.85W mm -2 , energy density 7.5W·s·mm -1 . Finally, the sample was taken out ...

Embodiment 3

[0034] Select the prepared Zr702 sample of 18×12×2mm, first use 800#, 1000#, 1200#, 2000# and 3000# sandpaper to polish the sample until it is bright. After the sample was polished, it was cleaned with absolute ethanol, and finally its surface was dried. Then the sample was placed on the YAG laser workpiece table and fixed with iron clips. Then, the protective gas pipeline was fixed above the surface of the sample, and argon with a purity of 99.9% was used as the protective gas to ensure an argon atmosphere around the sample. Then set the laser parameters and set the laser beam path. Start the laser, load the voltage, turn on the argon gas, and perform laser surface treatment on the surface of the Zr702 material. The process parameters of the laser surface treatment are: laser power 100W, scanning speed 8mm s -1 , Defocus amount +2mm, peak value 1KW, pulse width 5m s, frequency 20HZ, power density 127.4W mm -2 , Energy density 12.5W·s·mm -1 . Finally, the sample was taken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com