Flame retardant and wood-plastic composite material

A technology of wood-plastic composite materials and flame retardants, applied in the field of wood-plastic composite materials, can solve the problems of affecting the flame-retardant grade and weakening the flame-retardant performance of composite materials, and achieve the effect of slowing down the burning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the wood-plastic composite material of the above-mentioned embodiment is as follows: spray the flame retardant onto the surface of wood powder; PVC resin, wood powder sprayed with flame retardant, calcium carbonate, synergist, foaming agent, stabilizer , coupling agent, processing aid, and lubricant are mixed and configured into intermediate pellets; by spraying, the flame retardant can be evenly contacted with wood flour, and the mixing of materials is always improved during the mixing process, thereby improving the effect of flame retardancy ;

[0042] Extruded by twin-screw extruder;

[0043] Put the intermediary pellets into the extruder and heat to 130-190°C for extrusion; extruder barrel temperature is 130-180°C, mold temperature is 130-200°C, host speed is 10-30r / min, feeding speed 10~25r / min.

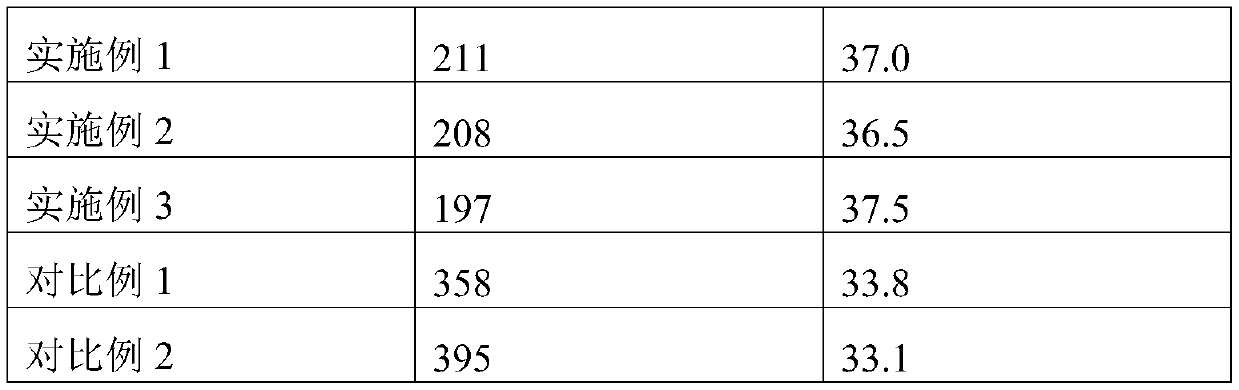

Embodiment 1

[0046] The wood-plastic composite material includes in parts by weight: 80 parts of PVC resin, 35 parts of wood powder, 15 parts of calcium carbonate, 35 parts of synergist, 1 part of foaming agent, 10 parts of stabilizer, 1 part of coupling agent, processing aid 10 parts of lubricant, 2 parts of lubricant and 20 parts of flame retardant;

[0047] Wherein, the shell component of the flame retardant is aluminum hydroxide, the middle layer component is zinc borate hydrate, and the core component is magnesium hydroxide; and, the particle diameter of the flame retardant is: D50<60nm, D90<100nm; the inner core and the middle layer are connected by an adhesive, and the middle layer is connected with the outer shell by an adhesive.

[0048] The weight part ratio of described aluminum hydroxide, hydrated boric acid zincate and magnesium hydroxide is 3: 2: 1;

[0049] The particle diameters of the aluminum hydroxide, zinc borate hydrate and magnesium hydroxide are all less than 20nm; ...

Embodiment 2

[0057] The wood-plastic composite material includes in parts by weight: 120 parts of PVC resin, 15 parts of wood powder, 35 parts of calcium carbonate, 15 parts of synergist, 3 parts of foaming agent, 5 parts of stabilizer, 2 parts of coupling agent, processing aid 6 parts of lubricant, 4 parts of lubricant and 8 parts of flame retardant;

[0058] Wherein, the shell component of the flame retardant is aluminum hydroxide, the middle layer component is zinc borate hydrate, and the core component is magnesium hydroxide; and, the particle diameter of the flame retardant is: D50<60nm, D90<100nm; the inner core and the middle layer are connected by an adhesive, and the middle layer is connected with the outer shell by an adhesive.

[0059] The weight part ratio of described aluminum hydroxide, hydrated boric acid zincate and magnesium hydroxide is 3: 2: 1;

[0060] The particle diameters of the aluminum hydroxide, zinc borate hydrate and magnesium hydroxide are all less than 20nm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com