Biological lysis treatment method for sludge

A treatment method and sludge technology, applied in biological sludge treatment, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of complicated operation, limited use conditions, expensive enzymes, etc., and achieve fast dissolution rate, The effect of saving carbon sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Domestication of seed mud

[0040] The sludge used for domestication comes from the residual sludge of the sewage plant operated by A / O process. The total suspended solids (TSS) in the sludge are 10147±210mg / L, and the volatile suspended solids (VSS) are 7416±170mg / L. A laboratory-scale thermophilic aerobic reactor (R 55 : 55°C; R 65 : 65°C; R 75 : 75° C.), the reactor was combined with a heat-collecting magnetic stirrer (150 rpm), and the volume of each reactor was 1 L. After the sludge is sieved to remove substances with a diameter of more than 1mm, it is added to the reactor, which is the domestication stage of the seed sludge. 1 / 5 volume of domesticated sludge in the reactor was replaced with fresh sludge every 3 days to provide nutrition for thermophilic bacteria, and the domestication time was 15 days.

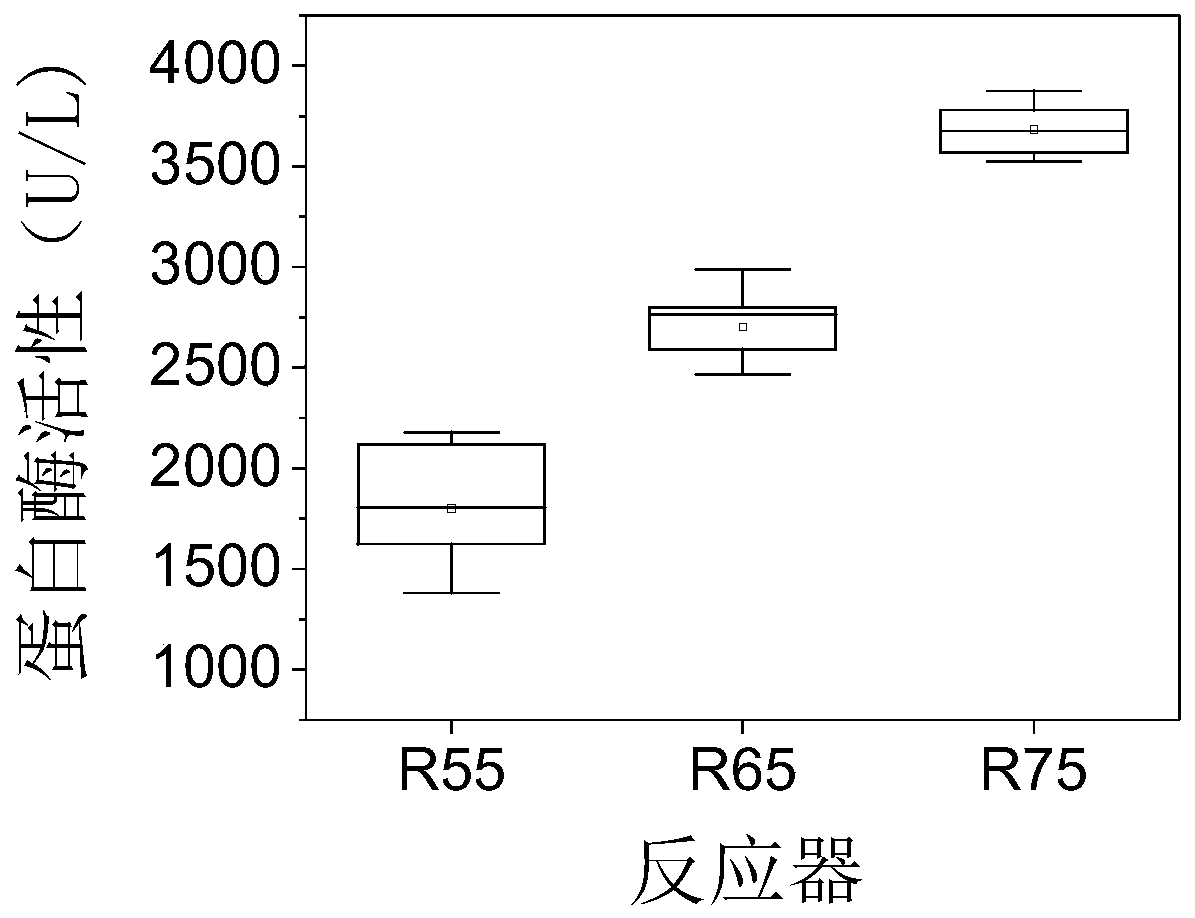

[0041] Protein is the main component in sludge, and the hydrolysis of protein is an important part of the process of dissolving sludge. The method of measurin...

Embodiment 2

[0043] Sludge Dissolution Experiment

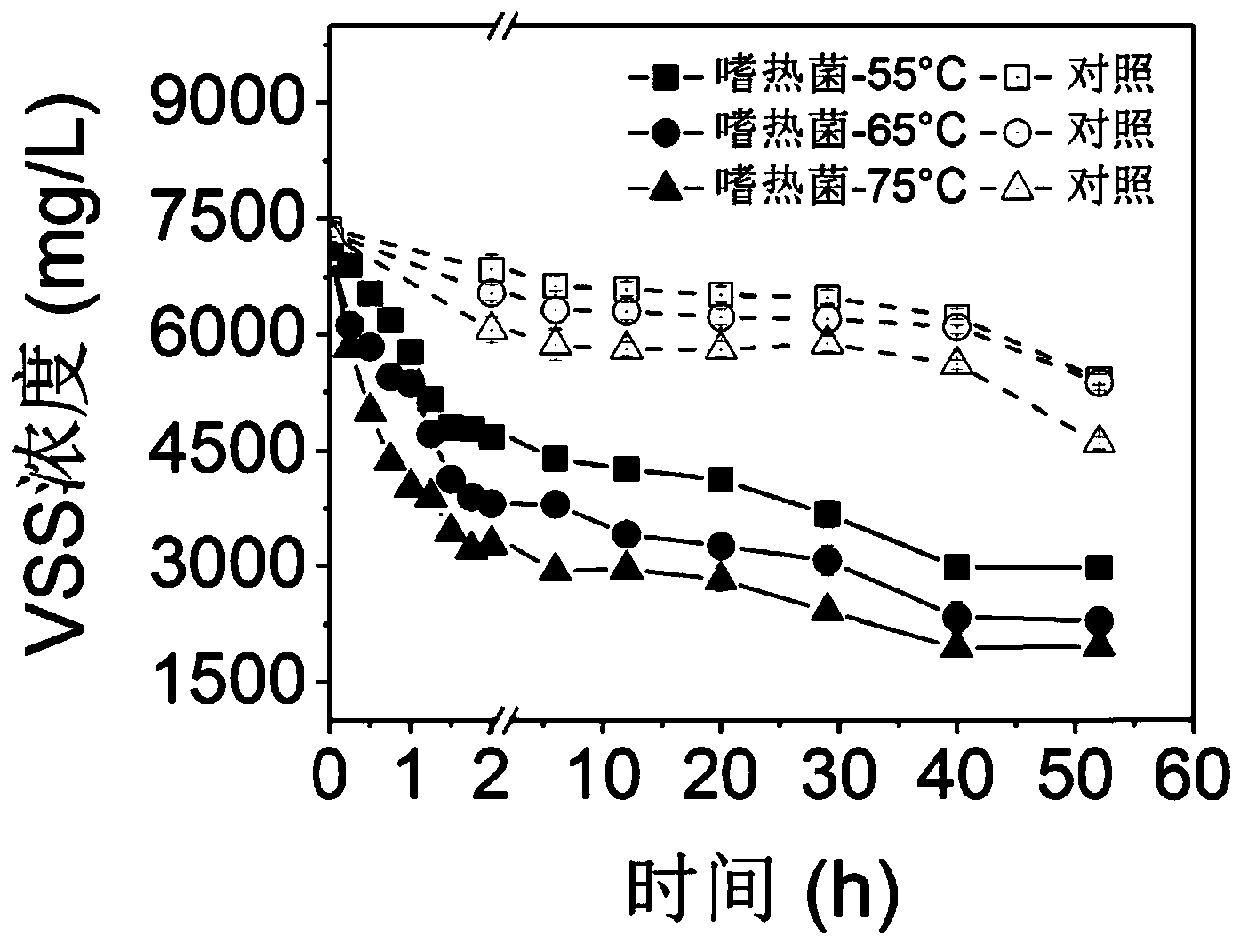

[0044] The analysis experiment of the thermophilic flora formed under the above three temperature conditions on the sludge dissolving performance is as follows.

[0045] Inoculate 5% of the domesticated seed sludge containing thermophilic bacteria in the sludge dissolving reactor to carry out the sludge dissolving experiment, and use three reactors without thermophilic bacteria as the control group, the control group and the experimental group respectively. The operating temperature is the same, and the operating conditions are the same as those in the acclimation stage. Samples were taken at different time points during the operation of the reactor, and the position of the liquid level in the reactor was recorded before and after sampling, and the evaporated water was replenished with distilled water. The concentration of VSS in solution at different time points was detected according to standard methods. The method for measuring the s...

Embodiment 3

[0049] Microbial population structure and function

[0050] Thermophilic communities in all reactors were assessed using Illumina amplicon sequencing. Sludge samples were collected from three acclimatization reactors that had been in operation for 15 days, and DNA samples were extracted from the sludge using the Fast DNA Spin Kit for soil (MP Biomedicals, LLC, USA). DNA concentration was then measured using NanoDrop (ND-1000, DE, USA). Bacterial 16S rRNA gene was PCR amplified with forward primer 515F and reverse primer 806R. And pyrosequencing was performed on the Illumina HiSeq platform.

[0051] A total of 605,480 cleantags were generated from 9 samples (three biological parallels) by Illumina HiSeq sequencing. After removing chimeric sequences, the effective tags were clustered into taxonomic operating units (OTUs) with 97% similarity, Deinococcas-Thermus phylum (Deinococcas-Thermus ) in the genus Thermus as the dominant genus in R55, R65 and R75 relative abundances wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com