Self-heating coating type low-temperature denitration catalyst and preparation method thereof

A low-temperature denitration and catalyst technology, applied in the field of denitration catalysts, can solve the problems of consuming a large heat source and increasing production costs, and achieve the effects of reducing regeneration costs, stable structure, and excellent ultra-low temperature catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

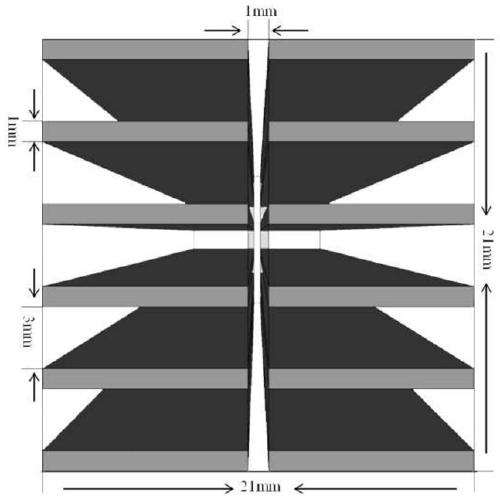

Image

Examples

Embodiment 1

[0066] (1) Surface treatment of electrothermal metal alloys

[0067] Place the electrothermal metal alloy substrate in 5% NaOH solution and soak for 5 minutes, take it out and rinse it with deionized water, then soak it in 5% nitric acid solution for 3 minutes, take it out and rinse it with deionized water;

[0068] (2)Al 2 o 3 Preparation of transition coating

[0069] Put the electrothermal metal alloy treated in step (1) into a mixture containing 0.204mg / L polyacrylic acid, 0.06g / L aluminum isopropoxide, 40.0g / Lγ-Al 2 o 3 Powder and 4.0g / L aluminum powder were electrodeposited in an anhydrous ethanol electrodeposition solution, the electrodeposition voltage was 20V, and after drying, they were kept at a high temperature of 800°C for 2h.

[0070] (3) Preparation of catalyst coating slurry

[0071] (a1) Carrier precursor sol configuration

[0072] Weigh 4.615g of titanyl sulfate and 0.687g of citric acid and add it to 13.845g of deionized, dissolve and bake in an oven a...

Embodiment 2

[0086] (1) Surface treatment of electrothermal metal alloys

[0087] Place the electrothermal metal alloy substrate in 5% NaOH solution and soak for 5 minutes, take it out and rinse it with deionized water, then soak it in 5% nitric acid solution for 3 minutes, take it out and rinse it with deionized water;

[0088] (2)Al 2 o 3 Preparation of transition coating

[0089] Put the electrothermal metal alloy treated in step (1) into a mixture containing 61.044mg / L polyacrylic acid, 0.6g / L aluminum isopropoxide, 40.0g / Lγ-Al 2 o 3 Powder and 4.0g / L aluminum powder were electrodeposited in an anhydrous ethanol electrodeposition solution, the electrodeposition voltage was 20V, and after drying, they were kept at a high temperature of 800°C for 2h.

[0090] (3) Preparation of catalyst coating slurry

[0091] (a1) Carrier precursor sol configuration

[0092] Weigh 8.800g of titanyl sulfate and 1.312g of citric acid and add it to 26.400g of deionized, dissolve and bake in an oven at ...

Embodiment 3

[0106] (1) Surface treatment of electrothermal metal alloys

[0107] Place the electrothermal metal alloy substrate in 5% NaOH solution and soak for 5 minutes, take it out and rinse it with deionized water, then soak it in 5% nitric acid solution for 3 minutes, take it out and rinse it with deionized water;

[0108] (2)Al 2 o 3 Preparation of transition coating

[0109] Put the electrothermal metal alloy treated in step (1) into a mixture containing 15.008mg / L polyacrylic acid, 0.3g / L aluminum isopropoxide, 40.0g / Lγ-Al 2 o 3 Powder and 4.0g / L aluminum powder were electrodeposited in an anhydrous ethanol electrodeposition solution, the electrodeposition voltage was 20V, and after drying, they were kept at a high temperature of 800°C for 2 hours;

[0110] (3) Preparation of catalyst coating slurry

[0111] (a1) Carrier precursor sol configuration

[0112] Weigh 18.030g of titanyl sulfate and 2.406g of citric acid and add it to 54.090g of deionized, dissolve and bake in an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| body surface area | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com