Thiolactic acid doped green rust geopolymer adsorbent and preparation method and application thereof

A geopolymer, thiolactic acid technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of narrow pH range, small adsorption capacity of heavy metals, and few types of heavy metals adsorbed, Achieve the effect of large adsorption capacity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

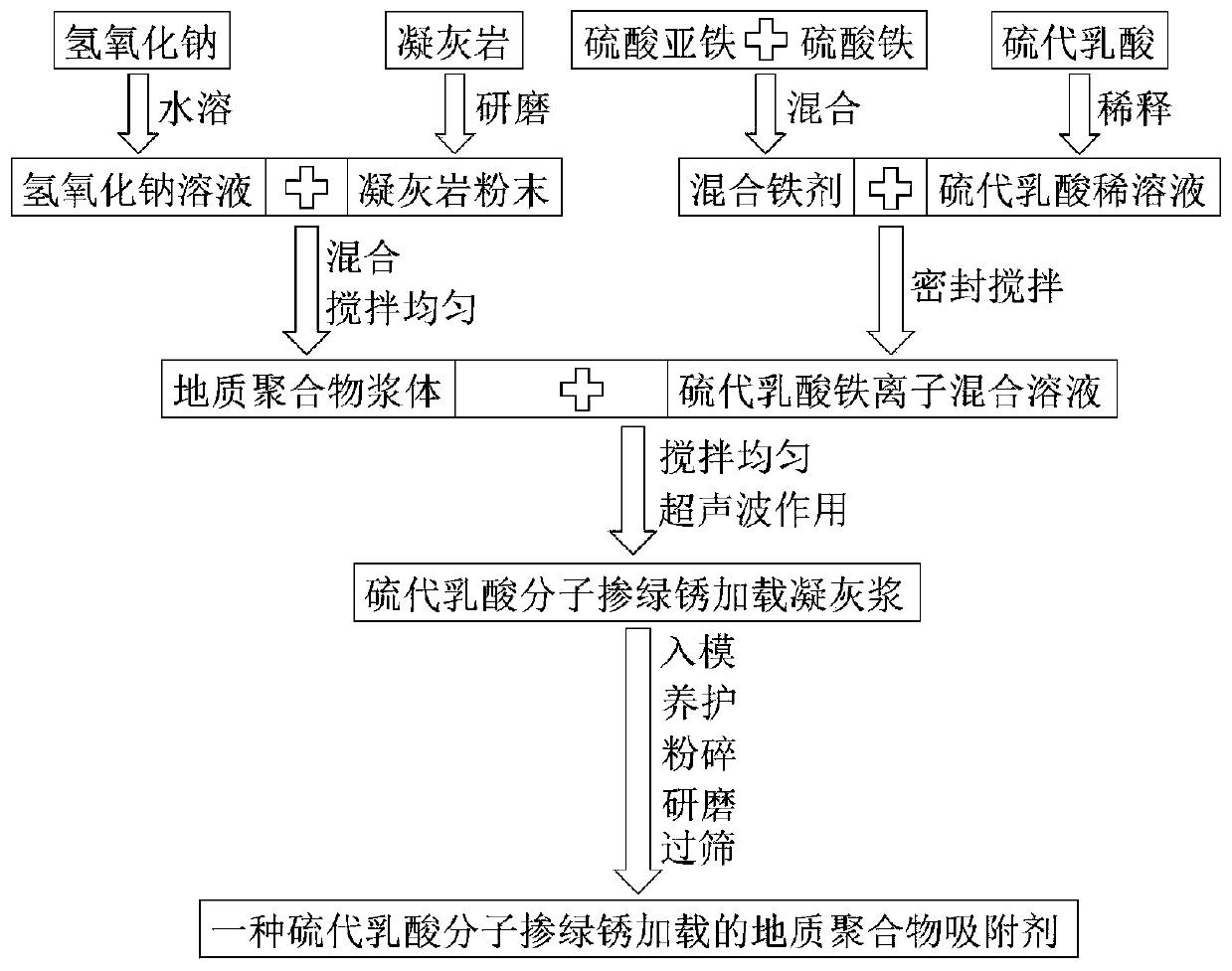

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Effect of Mass Ratio of Tuff Powder and Sodium Hydroxide Solution on the Heavy Metal Adsorption Performance of the Prepared Geopolymer Adsorbent

[0029] Preparation of geopolymer with thiolactic acid mixed with patina: Weigh sodium hydroxide and dissolve it in water to prepare 5M sodium hydroxide solution. Weigh the tuff, grind it, and pass through a 200-mesh sieve to get the tuff powder. According to the mass ratio of tuff powder to sodium hydroxide solution 1.05:1, 1.1:1, 1.15:1, 1.2:1, 1.35:1, 1.5:1, 1.55:1, 1.6:1, 1.65:1, the tuff powder and hydrogen The sodium oxide solution was mixed and stirred evenly to obtain nine sets of geopolymer slurries. Weigh ferrous sulfate and ferric sulfate respectively according to the molar ratio of ferrous ions and ferric ions of 2:1, and mix them to obtain a mixed ferric agent. Dilute 98% thiolactic acid with water to prepare 5% dilute thiolactic acid solution. Nitrogen gas was passed into the dilute thiolactic acid s...

Embodiment 2

[0036] Example 2 Influence of molar ratio of ferrous ions and ferric ions on the heavy metal adsorption performance of the prepared thiolactic acid mixed with patina geopolymer adsorbent

[0037] Preparation of geopolymer adsorbent with thiolactic acid mixed with patina: Weigh sodium hydroxide and dissolve it in water to prepare 10M sodium hydroxide solution. Weigh the tuff, grind it, and pass through a 300-mesh sieve to get the tuff powder. The tuff powder and the sodium hydroxide solution are mixed according to the mass ratio of the tuff powder and the sodium hydroxide solution at 1.5:1, and stirred evenly to obtain a geopolymer slurry. Weigh ferrous sulfate according to the molar ratio of ferrous ion and ferric ion 1:1, 1.5:1, 1.8:1, 2:1, 2.5:1, 3:1, 3.2:1, 3.5:1, 4:1 Mix with ferric sulfate to obtain nine groups of mixed iron preparations. Dilute 98% thiolactic acid with water to prepare nine groups of 10% dilute thiolactic acid solutions. Into the nine groups of 10% th...

Embodiment 3

[0043] Example 3 Influence of the mass ratio of ferric thiolactate ion mixed solution to geopolymer slurry on the heavy metal adsorption performance of the prepared thiolactic acid mixed with patina geopolymer adsorbent

[0044] Preparation of geopolymer adsorbent with thiolactic acid mixed with patina: Weigh sodium hydroxide and dissolve it in water to prepare 15M sodium hydroxide solution. Weigh the tuff, grind it, and pass through a 400-mesh sieve to obtain the tuff powder. The tuff powder and the sodium hydroxide solution are mixed according to the mass ratio of the tuff powder and the sodium hydroxide solution at 1.5:1, and stirred evenly to obtain a geopolymer slurry. Weigh ferrous sulfate and ferric sulfate respectively according to the molar ratio of ferrous ion and ferric ion of 3:1, and mix them to obtain a mixed ferric agent. Dilute 98% thiolactic acid with water to prepare 15% dilute thiolactic acid solution. Nitrogen gas was passed into the dilute thiolactic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com