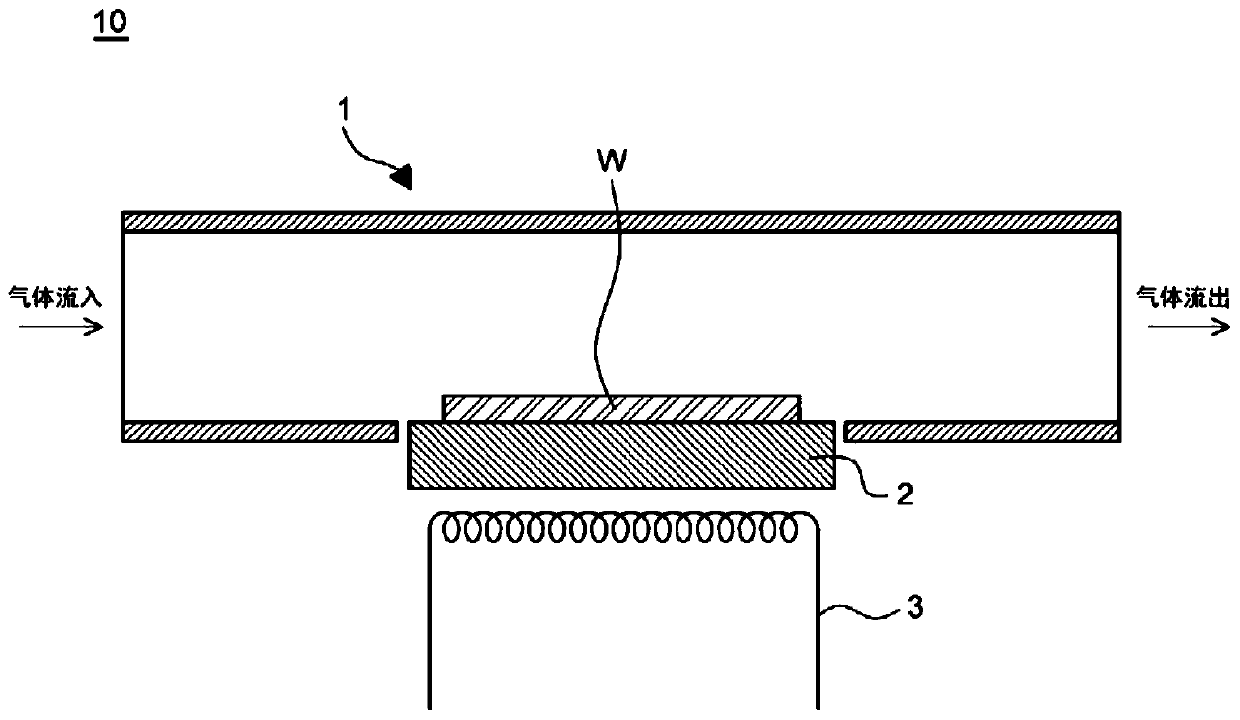

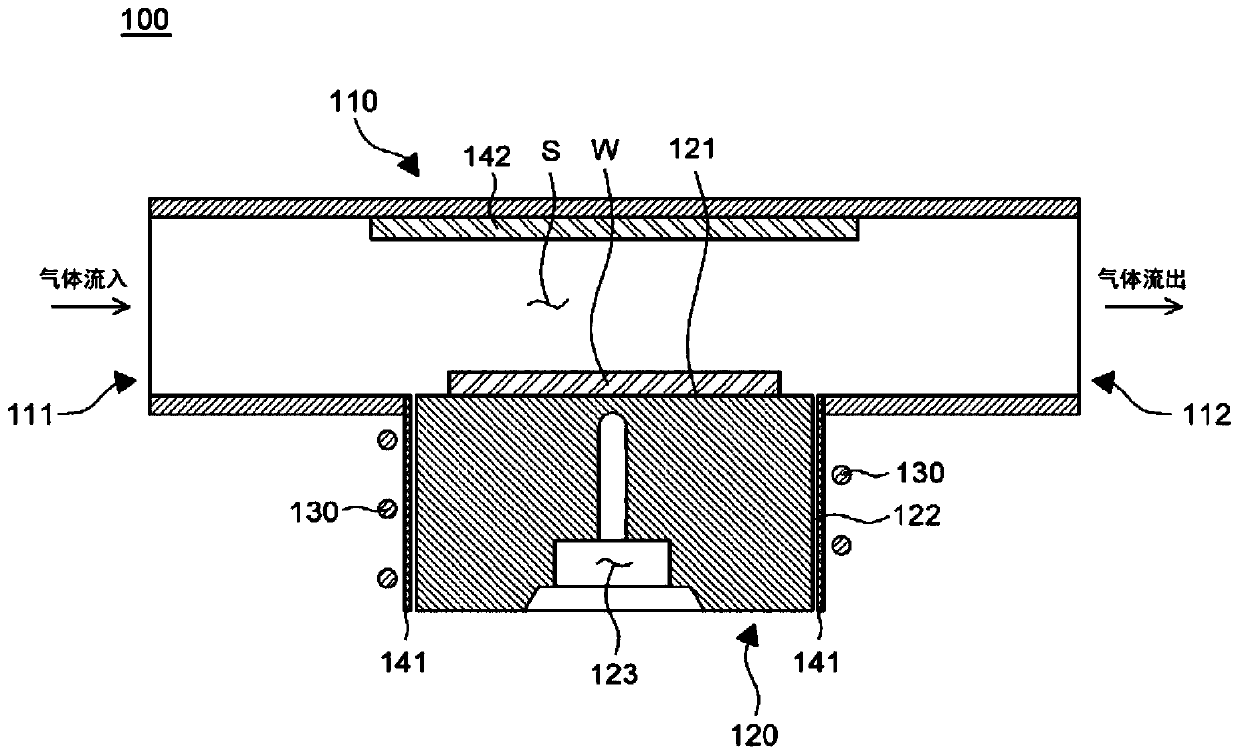

Susceptor and mocvd device comprising same

A susceptor and substrate technology, applied in gaseous chemical plating, coating, electrical components, etc., can solve the problems of low temperature, reduced characteristic uniformity, high manufacturing cost, and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] by reference to the attached Figure 1 The advantages, features and methods of realizing the present invention will be clarified with the embodiments described in detail later. However, the present invention is not limited to the embodiments disclosed below, and can be implemented in various forms different from each other. The scope of the present invention is provided with the understanding in mind, and the present invention is defined only by the scope of the claims.

[0052] Although first, second, etc. are used to describe various constituent elements, it is obvious that these constituent elements are not limited to these terms. These terms are used only to distinguish one element from another element. Therefore, it is obvious that the first constituent element mentioned below may also be the second constituent element within the scope of the technical concept of the present invention. At the same time, it is obvious that even if it is described that the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com