Engine oil-gas separation device and engine

A separation device, oil and gas separation chamber technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as unfavorable condensed lubricating oil backflow, etc., to facilitate the condensation of liquid substances, increase the contact or collision area, and improve quality. effect on efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

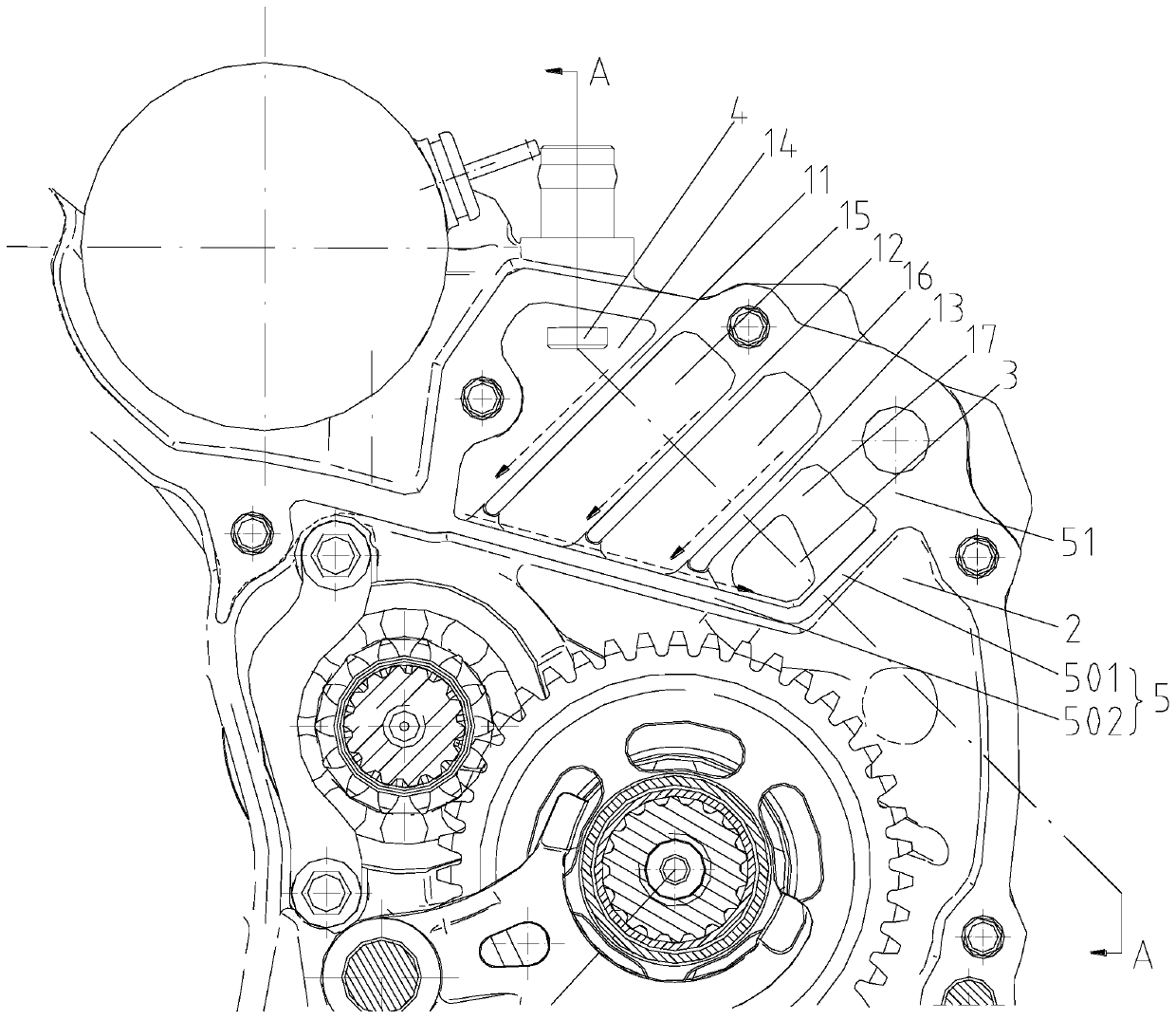

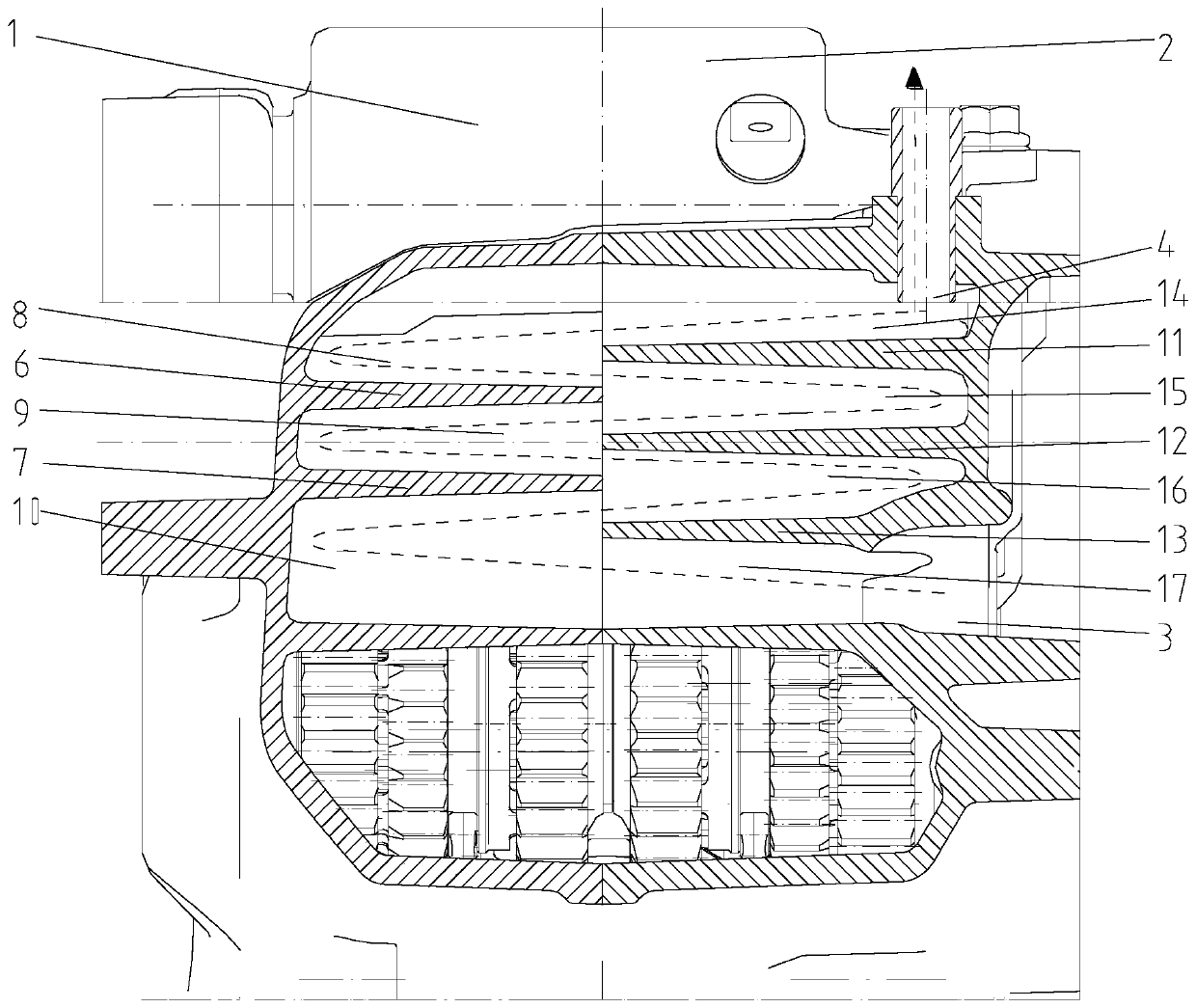

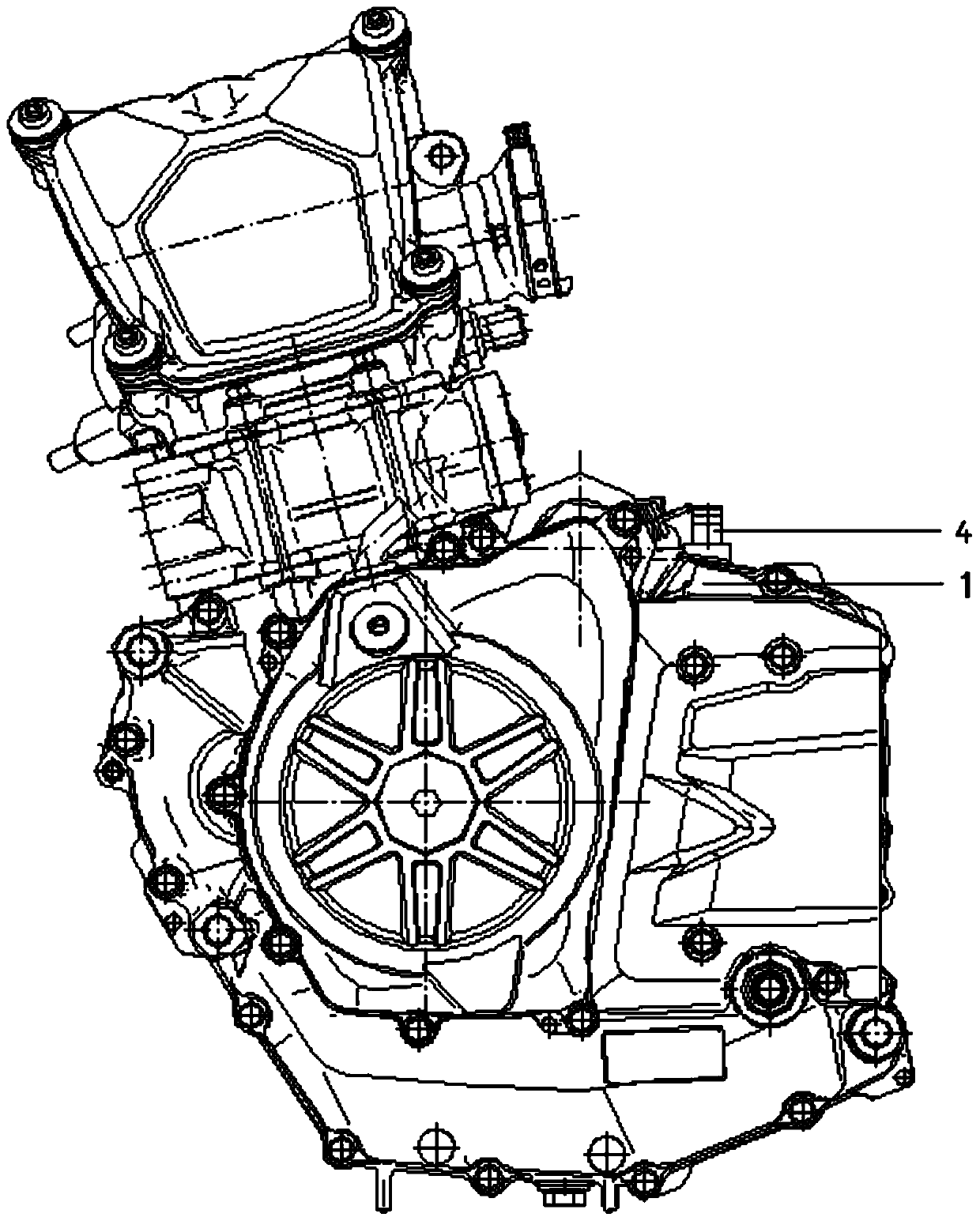

[0019] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the A-A direction after the left and right crankcases of the present invention are combined. As shown in the figure: the engine oil-gas separation device and the engine of this embodiment include an isolation plate 5 connected to the crank chamber, and the isolation plate 5 isolates the oil-air separation chamber from the crankcase, and the oil-air separation chamber is set There is a labyrinth channel, and the oil-gas separation chamber is also provided with an air inlet 3 communicated with the inlet end of the labyrinth channel and an exhaust port 4 communicated with the exhaust end of the labyrinth channel, and the air inlet 3 is located in the oil-gas separation chamber bottom. The air inlet 3 is connected to the exhaust port of the crankcase, and the air outlet 4 is connected to the air inlet of the engine air intake system, which is the prior...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com