Diamond engineering thin-wall drilling tool bit provided with bottom groove

A thin-wall drill and diamond technology, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of shortening the service life of the product, weakening the overall strength of the cutter head, broken teeth, etc., so as to prolong the service life and solve the problem of weakening the cutter head. life, the effect of reducing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

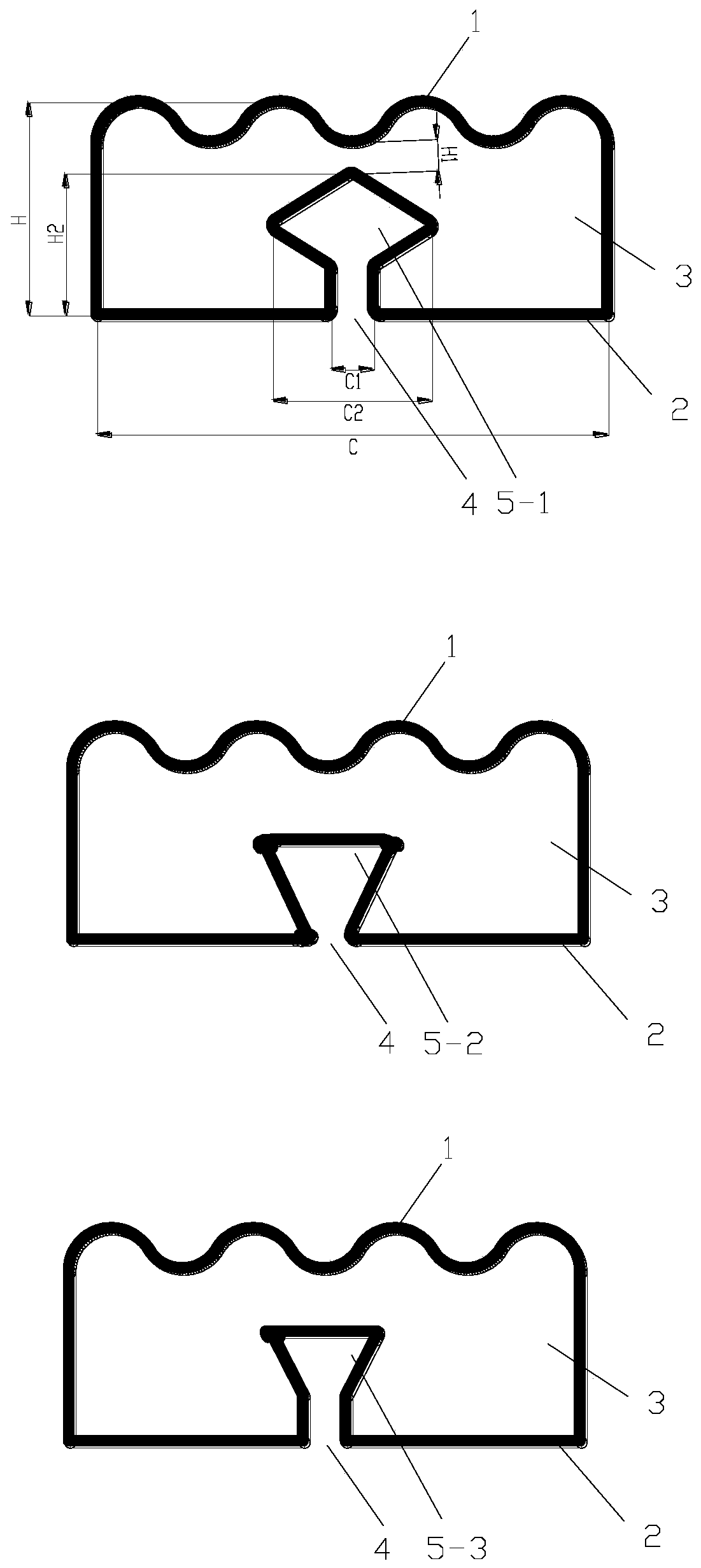

[0023] This embodiment relates to the structural description and preparation of the diamond engineering thin-wall drill bit with bottom groove of the present invention.

[0024] Such as figure 1 As shown, the diamond engineering thin-wall drill bit of the present invention includes a toothed end 1, and the tooth shape of the toothed end 1 is corrugated; it also includes a tail end 2 opposite to the toothed end 1, and the tail end 2 is planar , for fixing on the drill pipe of the engineering thin-walled drill; it also includes an arc-shaped surface 3 on the side of the cutter head connecting the tooth-shaped end 1 and the tail end 2, and the thickness d of the arc-shaped surface 3 is 3-7 mm. A bottom groove 4 is set at the center of the tail end 2, the ratio of the length C1 of the bottom groove 4 to the length C of the cutter head C1:C≤1:4; a slot hole is set on the arc surface 3, and the slot hole can be a diamond-shaped slot hole 5 -1 or triangular shaped slot 5-2 or trapez...

Embodiment 21

[0035] This example relates to the evaluation of the performance of the cutter head in Examples 1.1 to 1.3.

[0036] The cutter head of embodiment 1.1~1.3 all adopts Ф63-380 drill bit (namely the drill bit of outer diameter 63mm, length 380mm), adopts test drill block (standard c40 cement concrete, thickness 240mm, contains 4 18mm steel bars, namely drilling depth 240mm , four 18mm steel bars need to be broken in the middle), and a drill rig with a power of 4kw and a speed of 800r / min was used to test the performance of the cutter head. The cutter heads in each embodiment were drilled smoothly, and the sharpness of the cutter head was greatly enhanced. There was no change in the middle and late stages. Blunt phenomenon; there is no stuck drill in the drilling and cutting process, it is easy to take the core, and it needs to add enough water for cooling; the performance data of the diamond saw blades in Examples 1.1 to 1.3 are shown in Table 2 below:

[0037]

[0038]

Embodiment 22

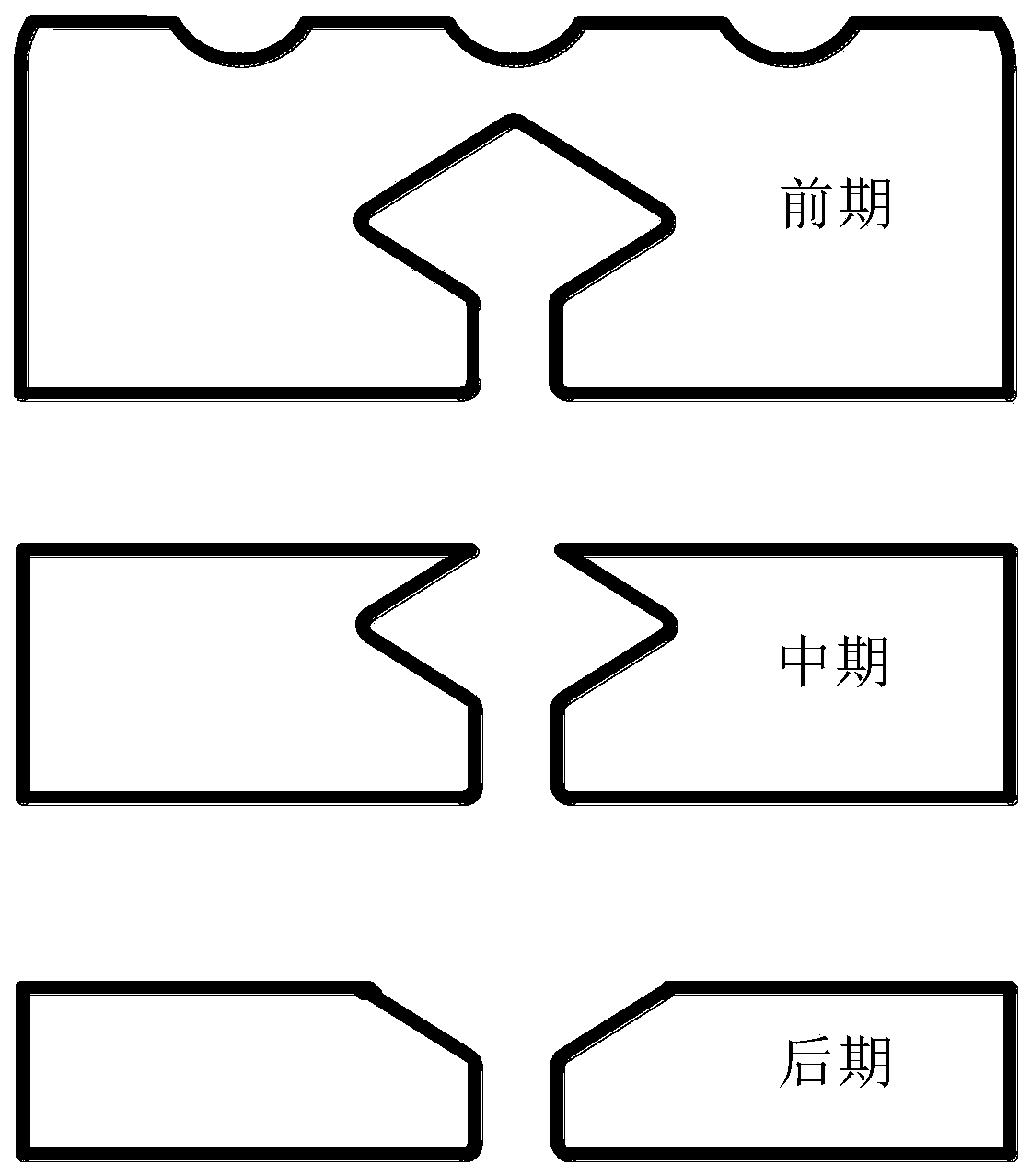

[0040] This embodiment relates to the wear condition of the thin-walled drill bit of the present invention during use.

[0041] Such as figure 2 As shown, the thin-walled drill bit of the present invention has a corrugated tooth design in the early stage to increase the sharpness of the drill bit when drilling. The top surface forms multiple knife-tooth shapes, similar to the sharpness of Great Wall teeth, thereby improving the sharpness of the drill bit in the middle and late stages. However, there is no difference between the conventional corrugated tooth bit and the flat tooth bit in the middle and later stages.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com