Magnetic pulse treatment method for reducing residual stress of magnesium alloy plate

A technology of residual stress and treatment method, which is applied to magnetic pulse treatment to reduce residual stress of magnesium alloy sheets, residual stress generated during extrusion and cooling, and deformed magnesium alloys in the field of rolling, which can solve the problem of weak magnetic field response and paramagnetic properties. The effect of material effect is not obvious, so as to achieve the effect of no damage to the appearance, optimization of the reduction process, and realization of residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, a magnetic pulse treatment method for reducing the residual stress of a magnesium alloy plate according to the present invention is used to perform residual stress reduction treatment on a 150mm×250mm×4.5mm magnesium alloy AZ31 rolled plate, and the specific steps are as follows:

[0048] (1) First, carry out residual stress detection on the AZ31 magnesium alloy rolled plate before the reduction treatment, and design the installation position of the magnetic pulse generator according to the detection results, and perform reduction treatment on the stress concentration part;

[0049] (2) Connect the programmable control pulse DC power supply output device and the magnetic pulse generator with a power transmission cable, and turn on the water cooling system;

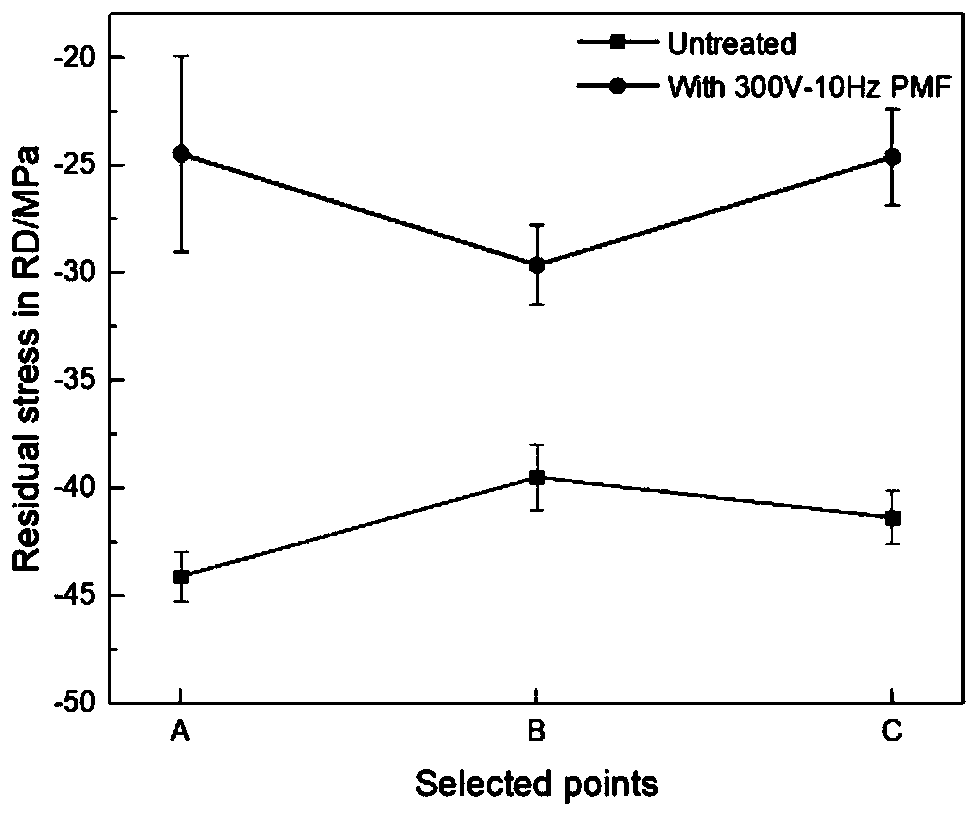

[0050] (3) Set the pulse frequency to 10Hz through PLC programming, turn on the programmable control pulse DC power output device, adjust the pulse voltage to 300V, and the processing time is 60mi...

Embodiment 2

[0052] In this embodiment, a magnetic pulse treatment method for reducing the residual stress of a magnesium alloy plate according to the present invention is used to perform residual stress reduction treatment on a 150mm×250mm×4.5mm magnesium alloy AZ31 rolled plate, and the specific steps are as follows:

[0053] (1) First, carry out residual stress detection on the AZ31 magnesium alloy rolled plate before the reduction treatment, and design the installation position of the magnetic pulse generator according to the detection results, and perform reduction treatment on the stress concentration part;

[0054] (2) Connect the programmable control pulse DC power supply output device and the magnetic pulse generator with a power transmission cable, and turn on the water cooling system;

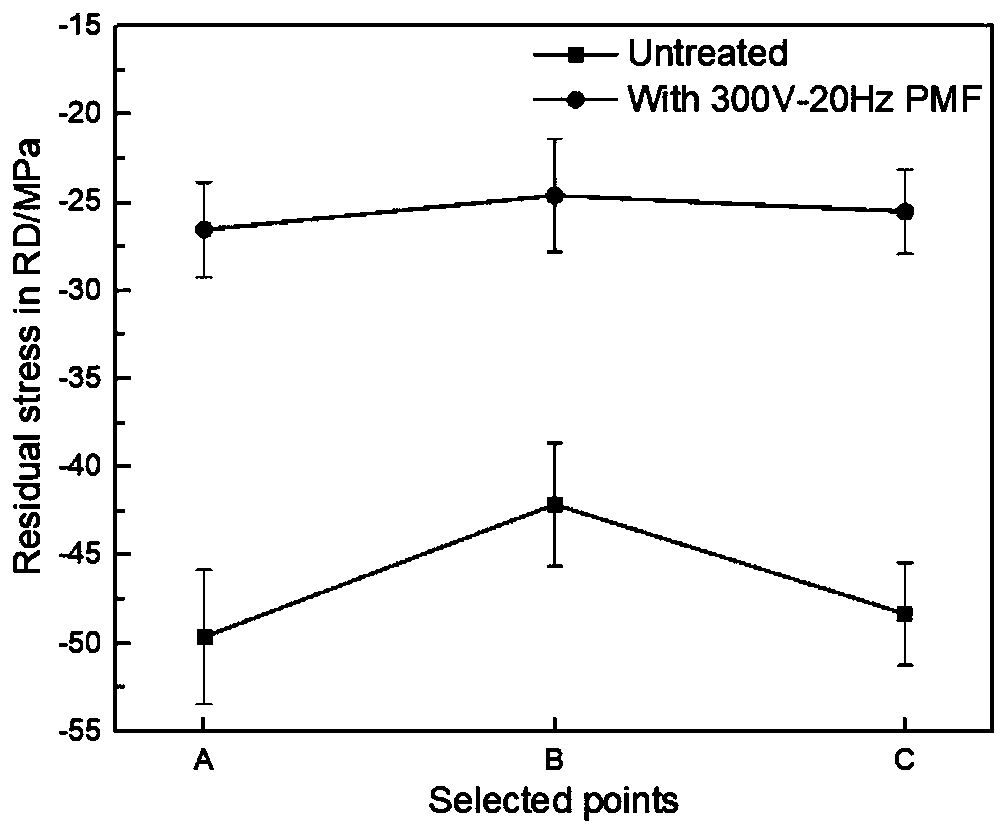

[0055] (3) Set the pulse frequency to 20Hz through PLC programming, turn on the programmable control pulse DC power output device, adjust the pulse voltage to 300V, and the processing time is 60mi...

Embodiment 3

[0057] In this embodiment, a magnetic pulse treatment method for reducing the residual stress of magnesium alloy plates according to the present invention is used to perform residual stress reduction treatment on extruded plates of magnesium alloy AZ31 with a size of 250mm×60mm×8mm. The specific steps are as follows:

[0058] (1) First, carry out residual stress detection on the AZ31 magnesium alloy rolled plate before the reduction treatment, and design the installation position of the magnetic pulse generator according to the detection results, and perform reduction treatment on the stress concentration part;

[0059] (2) Connect the programmable control pulse DC power supply output device and the magnetic pulse generator with a power transmission cable, and turn on the water cooling system;

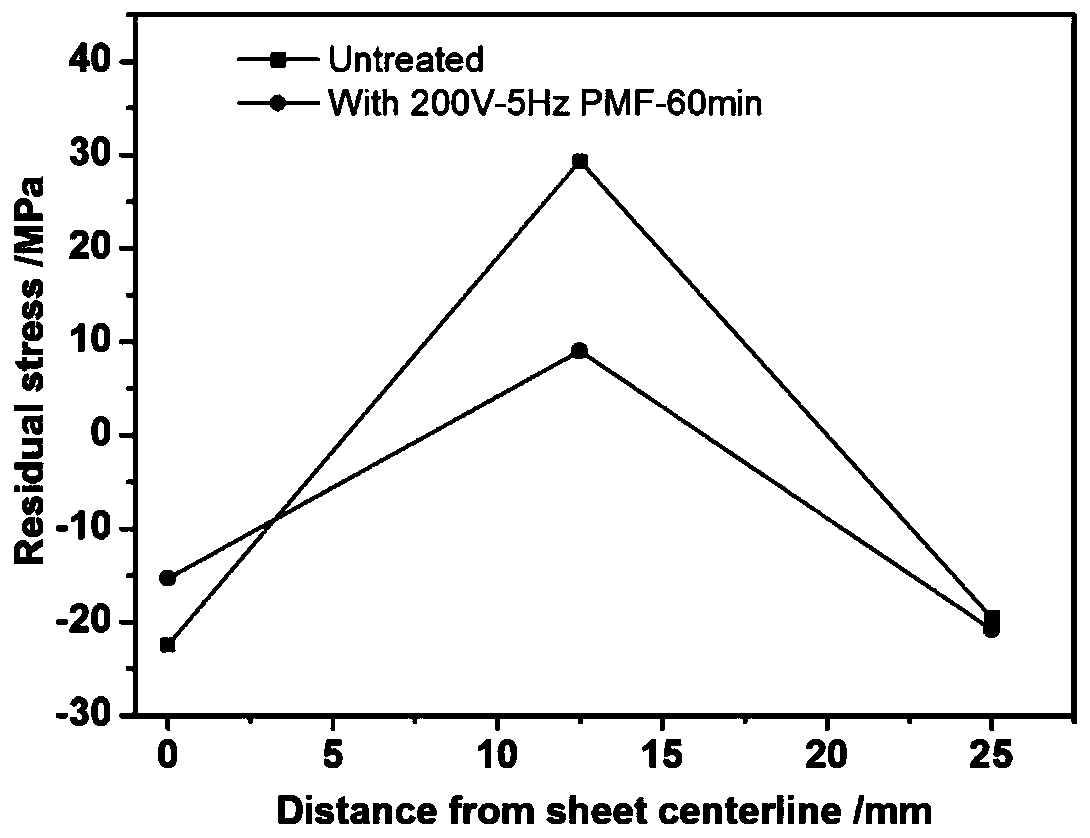

[0060] (3) Set the pulse frequency to 5Hz through PLC programming, turn on the programmable control pulse DC power output device, adjust the pulse voltage to 200V, and the processing ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com