Viscoelastic surfactant system based on oligomerization agent and application thereof

A surfactant and viscoelastic technology, applied in the field of oil exploration, can solve problems such as easy blockage of pores, reduce viscosity of heavy oil, and irregular oil-water front, so as to improve water flooding efficiency, increase water phase viscosity, and increase sweep volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0028] Preparation example 1 prepares ethoxylated quaternary ammonium salt type dimeric surfactant C 3 h 6 -2C 12 EO 3

[0029] (1) Add 18.5g (100 mmol) of the weighed raw material dodecylamine into a reaction kettle equipped with a stirring device, heat to 150°C while blowing nitrogen, and add 26.4g (600 mM) of ethylene oxide after 40 minutes. millimole), the temperature is maintained at 150°C, the pressure is controlled <0.80MPa, and the reaction is stirred for 1 hour. After the reaction is completed, the system is purged with nitrogen, and after cooling, it is neutralized and dehydrated to obtain the intermediate dodecyl polyoxyethylene ether tertiary amine 44 g, 98% yield.

[0030] (2) Weigh 22.5 g (50 mmol) of the intermediate dodecyl polyoxyethylene ether tertiary amine and 4 g (20 mmol) of 1,3-dibromopropane. Add the weighed raw materials into a reactor with a reflux and stirring device, add 800 grams of isopropanol, and after 3 days of reflux reaction, stop the re...

preparation example 2

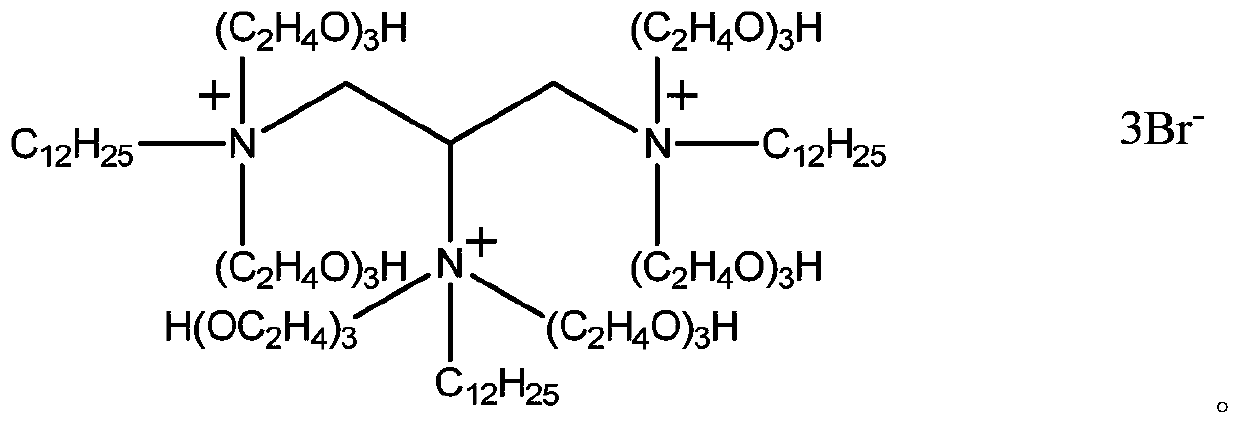

[0032] Preparation example 2 prepares ethoxylated quaternary ammonium salt type trimeric surfactant C 3 h 5 -3C 12 EO 3

[0033] (1) The preparation of the intermediate lauryl polyoxyethylene ether tertiary amine is the same as in Example 1.

[0034] (2) Weigh 22.5 g (50 mmol) of the intermediate dodecyl polyoxyethylene ether tertiary amine and 4.18 g (15 mmol) of 1,2,3-tribromopropane. Add the weighed raw materials into a reactor with a reflux and stirring device, add 800 grams of isopropanol, and after 3 days of reflux reaction, stop the reaction, evaporate the solvent under reduced pressure, and obtain 8.5 grams of pure Product C 3 h 5 -3C 12 EO 3 , 35% yield; its structural formula is as follows:

[0035]

preparation example 3

[0036] Preparation example 3 prepares ethoxylated quaternary ammonium salt type tetrameric surfactant C 5 h 8 -4C 12 EO 3

[0037] (1) The preparation of the intermediate lauryl polyoxyethylene ether tertiary amine is the same as in Example 1.

[0038] (2) Weigh 22.5 grams (50 mmol) of the intermediate dodecyl polyoxyethylene ether tertiary amine and 3.84 grams (10 mmol) of tetrabromopentaerythritol. The weighed raw materials are added to the reactor with reflux and stirring device, 800 grams of isopropanol is added, after reflux reaction for 3 days, the reaction is stopped, the solvent is evaporated under reduced pressure, and after recrystallization, 4.36 grams of pure Product C 5 h 8 -4C 12 EO 3 , yield 20%; Its structural formula is as follows:

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com