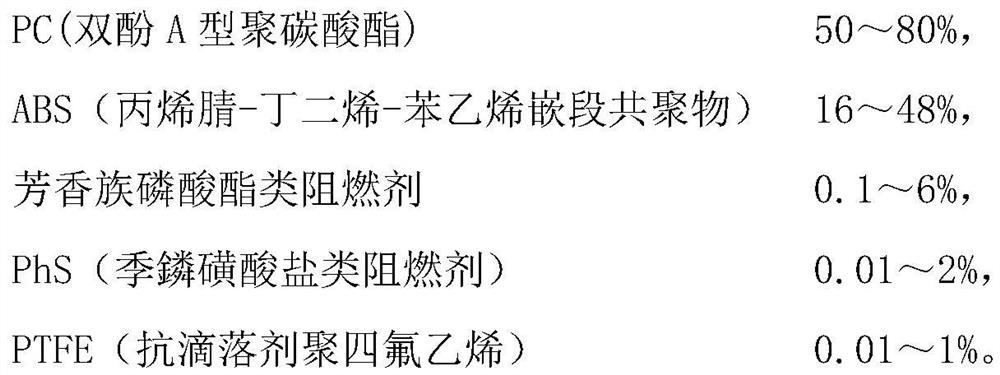

A kind of pc/abs flame retardant composite material and preparation method thereof

A technology of flame retardant composite materials and flame retardants, which is applied in the field of PC/ABS flame retardant composite materials and its preparation, can solve the problems affecting the mechanical properties, thermal stability and hydrolysis resistance of polymer materials, and achieve good flame retardancy Synergistic effect, cost reduction, effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment relates to a PC / ABS flame-retardant composite material and its preparation method; its preparation specifically includes the following steps:

[0030] a. Determine the composition formula of the material:

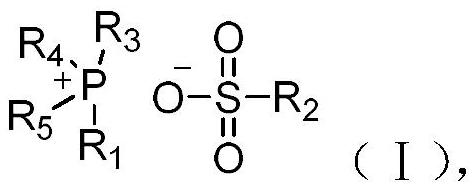

[0031] PC (bisphenol A polycarbonate): 37 grams; ABS (acrylonitrile-butadiene-styrene block copolymer): 9 grams; BDP (bisphenol A bis(diphenyl phosphate)): 3 grams; TPP (triphenyl phosphate): 0 grams; PhS (quaternary phosphonium sulfonate compounds, : 1 g; PTFE (anti-dripping agent polytetrafluoroethylene): 0.225 g.

[0032] b. Preparation of flame retardant composite materials:

[0033] Weigh the ingredients according to the above formula; blend, banbury evenly at 205°C in an internal mixer; discharge, unload, and pelletize to prepare a flame-retardant PC / ABS engineering composite material.

[0034] c. The resulting mixture is prepared into a test strip, and compared with the pure PC / ABS alloy test strip, the following properties are determined: ...

Embodiment 2

[0048] a. Determine the composition formula of the material:

[0049] PC (bisphenol A polycarbonate): 37 grams; ABS (acrylonitrile-butadiene-styrene block copolymer): 9 grams; BDP (bisphenol A bis(diphenyl phosphate)): 0 Gram; TPP (triphenyl phosphate): 3 grams; PhS (quaternary phosphonium sulfonate compounds, : 1 g; PTFE (anti-dripping agent polytetrafluoroethylene): 0.225 g.

[0050] b. Preparation of flame retardant composite materials:

[0051] Weigh the ingredients according to the above formula; blend, banbury evenly at 210°C in an internal mixer; discharge, unload, and pelletize to prepare a flame-retardant PC / ABS engineering composite material.

[0052] c. The resulting mixture is prepared into a test strip, and compared with the pure PC / ABS alloy test strip, the following properties are determined:

[0053] Flame retardant:

[0054] UL-94 vertical combustion: V-0 (according to ASTM D 635-77, 127mm 3 ×12.7mm 3 ×3mm 3 )

[0055] Limiting oxygen index: increased...

Embodiment 3

[0066] a. Determine the composition formula of the material:

[0067] PC (bisphenol A polycarbonate): 37 grams; ABS (acrylonitrile-butadiene-styrene block copolymer): 9 grams; BDP (bisphenol A bis(diphenyl phosphate)): 3 grams; TPP (triphenyl phosphate): 0 grams; PhS (quaternary phosphonium sulfonate compounds, : 1 g; PTFE (anti-dripping agent polytetrafluoroethylene): 0.225 g.

[0068] b. Preparation of flame retardant composite materials:

[0069] Weigh the ingredients according to the above formula; blend, banbury evenly at 200°C in an internal mixer; discharge, unload, and pelletize to prepare a flame-retardant PC / ABS engineering composite material.

[0070] c. The resulting mixture is prepared into a test strip, and compared with the pure PC / ABS alloy test strip, the following properties are determined:

[0071] Flame retardant:

[0072] UL-94 vertical combustion: V-0 (according to ASTM D 635-77, 127mm 3 ×12.7mm 3 ×3mm 3 )

[0073] Limiting oxygen index: increase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com