Antibacterial agent and wood-plastic composite material

A technology of wood-plastic composite materials and antibacterial agents, which is applied in the field of wood-plastic composite materials, can solve problems such as affecting the performance and life of the wood-plastic composite material, degrading the wood-plastic composite material, and the hazards of the wood-plastic composite material, so as to improve the surface effect and enhance the interface effect , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

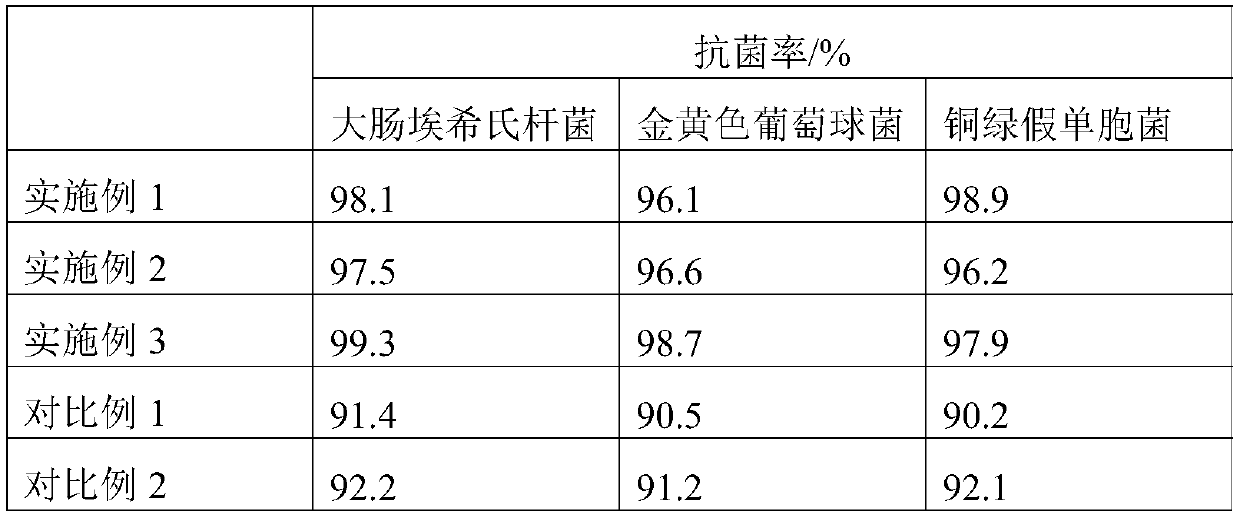

Examples

Embodiment 1

[0045] The wood-plastic composite material includes in parts by weight: 80 parts of PVC resin, 35 parts of wood powder, 15 parts of calcium carbonate, 35 parts of synergist, 1 part of foaming agent, 10 parts of stabilizer, 2 parts of coupling agent, processing aid 6 parts of lubricant, 4 parts of lubricant, 1 part of antibacterial agent;

[0046] Wherein, the antibacterial agent includes: shell: the shell component is organosilicon quaternary ammonium salt; middle layer, the middle layer component is polyhexamethylene guanidine hydrochloride; inner core. The inner core component is isothiazolinone; and, the particle diameter of the antibacterial agent is: D50<5 μm, D90<12 μm. The weight ratio of the organosilicon quaternary ammonium salt, polyhexamethyleneguanidine hydrochloride and isothiazolinone is 5:3:2.

[0047] Described calcium carbonate is heavy calcium carbonate.

[0048] The stabilizer is a calcium zinc stabilizer.

[0049] The lubricant is paraffin.

[0050] The...

Embodiment 2

[0054] The wood-plastic composite material includes in parts by weight: 120 parts of PVC resin, 15 parts of wood powder, 35 parts of calcium carbonate, 15 parts of synergist, 1 part of foaming agent, 10 parts of stabilizer, 1 part of coupling agent, processing aid 10 parts of lubricant, 2 parts of lubricant, 3 parts of antibacterial agent;

[0055] Wherein, the antibacterial agent includes: shell: the shell component is organosilicon quaternary ammonium salt; middle layer, the middle layer component is polyhexamethylene guanidine hydrochloride; inner core. The inner core component is isothiazolinone; and, the particle diameter of the antibacterial agent is: D50<5 μm, D90<12 μm. The weight ratio of the organosilicon quaternary ammonium salt, polyhexamethyleneguanidine hydrochloride and isothiazolinone is 5:3:2.

[0056] Described calcium carbonate is light calcium carbonate.

[0057] The stabilizer is an organotin stabilizer.

[0058] Described lubricant is stearic acid.

...

Embodiment 3

[0063] The wood-plastic composite material includes in parts by weight: 100 parts of PVC resin, 25 parts of wood powder, 25 parts of calcium carbonate, 25 parts of synergist, 2 parts of foaming agent, 7.5 parts of stabilizer, 1.5 parts of coupling agent, processing aid 8 parts of agent, 3 parts of lubricant, 2 parts of antibacterial agent;

[0064] Wherein, the antibacterial agent includes: shell: the shell component is organosilicon quaternary ammonium salt; middle layer, the middle layer component is polyhexamethylene guanidine hydrochloride; inner core. The inner core component is isothiazolinone; and, the particle diameter of the antibacterial agent is: D50<5 μm, D90<12 μm. The weight ratio of the organosilicon quaternary ammonium salt, polyhexamethyleneguanidine hydrochloride and isothiazolinone is 5:3:2.

[0065] Described calcium carbonate is the mixture of heavy calcium carbonate, light calcium carbonate, complex calcium carbonate.

[0066] The stabilizer is a mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com