Reinforced polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of plastics, can solve the problems of high shrinkage rate, poor compatibility of polar polymers, low mechanical strength, etc., to achieve the effect of improving interface function, improving interface strength, and purifying air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

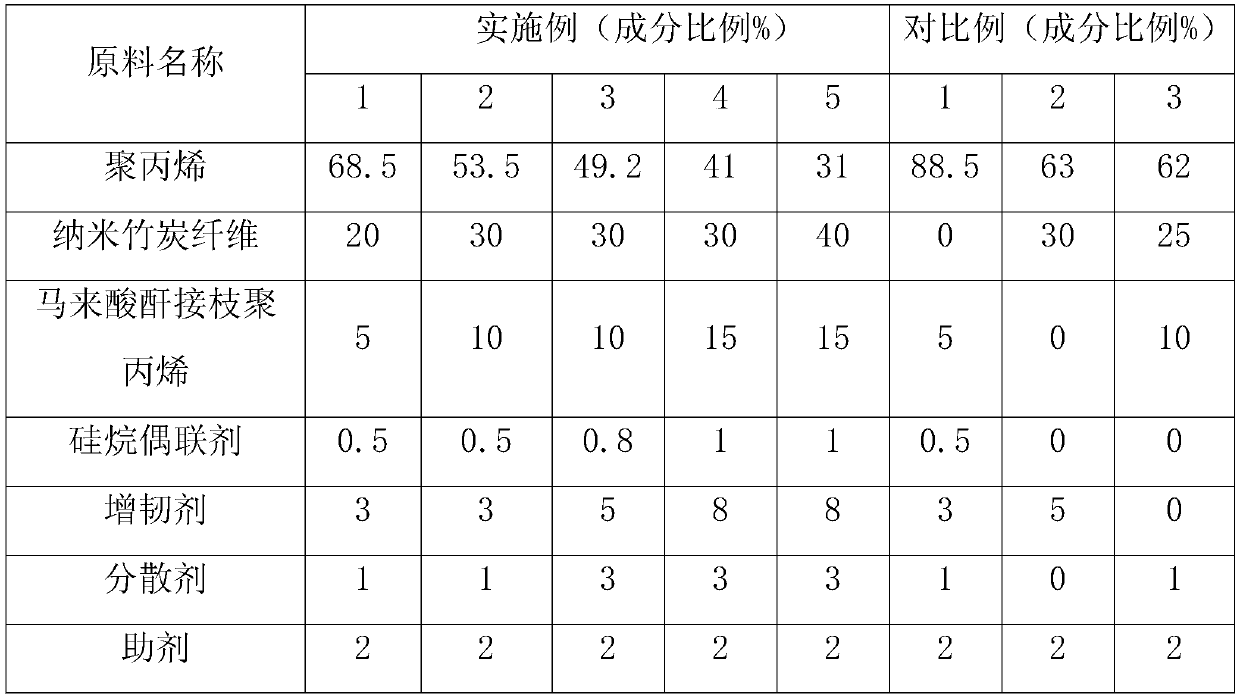

[0024] The reinforced polypropylene composite material is characterized in that: by weight percentage, it includes 30-69% of polypropylene, 20-33% of bamboo charcoal fiber, 5-15% of maleic anhydride grafted polypropylene, 0.5-1% of coupling agent, Toughening agent 3-8%, dispersant 1-3% and auxiliary agent 1.5%-3%. Bamboo charcoal is another brand-new environmentally friendly material with excellent performance developed by bamboo resources. Bamboo charcoal is formed after bamboo is dried and carbonized at 800 degrees. Bamboo charcoal has a strong ability to absorb and decompose, can absorb moisture and dry, deodorize and antibacterial, and has the properties of negative ion penetration. Bamboo charcoal fiber uses nanotechnology to micronize bamboo charcoal first, then process nano-scale bamboo charcoal micropowder through high-tech technology, and then use traditional chemical fiber preparation process to spin and form qualified bamboo charcoal fiber.

[0025] The coupling ag...

no. 2 example

[0035] This reinforced polypropylene composite material is different from the first embodiment in that it includes 53.5% polypropylene, 30% bamboo charcoal fiber, 10% maleic anhydride grafted polypropylene, 0.5% vinyl silane coupling agent, Toughening agent 3%, dispersant 1% and auxiliary agent 2%.

[0036] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

no. 3 example

[0038] This reinforced polypropylene composite material is different from the first embodiment in that it includes 49.2% polypropylene, 30% bamboo charcoal fiber, 10% maleic anhydride grafted polypropylene, 0.8% vinyl silane coupling agent, Toughening agent 5%, dispersant 3% and auxiliary agent 2%.

[0039] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com