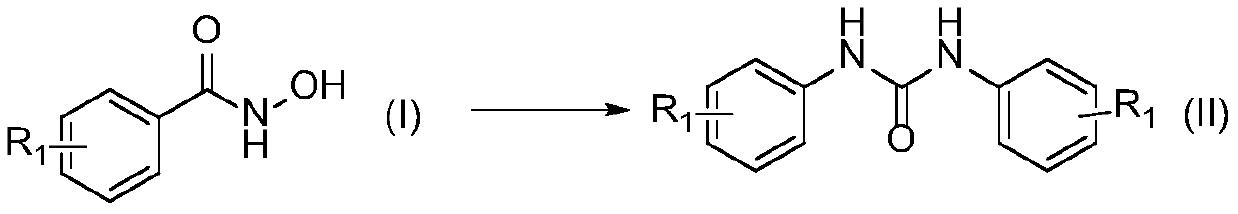

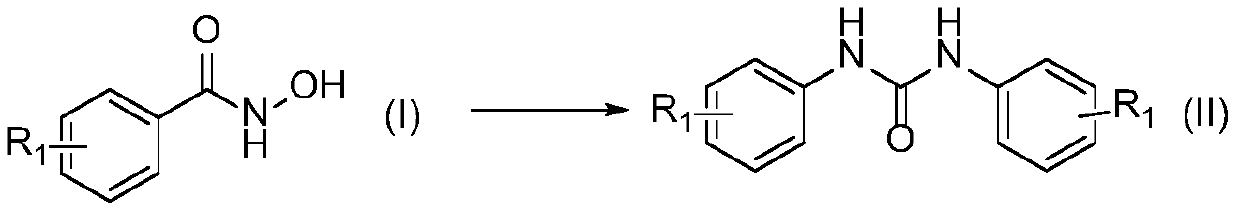

Preparation method of symmetric urea compound

A compound and urea technology, applied in the field of preparation of symmetrical urea compounds, can solve the problems of unfriendly environment, unfavorable large-scale application, etc., and achieve the effects of good yield, wide substrate applicability and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

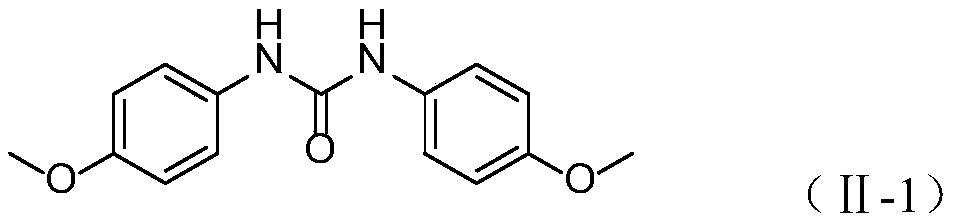

[0025] Embodiment 1: the preparation of 1,3-bis (4-methoxyphenyl) urea

[0026] In a 500mL single-necked flask, add 4-methylphenylhydroxamic acid (formula Ⅰ-1, R 1 = 4-OCH 3 ) 23.40g (140mmol), 150mL water, 45.24g (2.5eq, 350mmol) DIPEA, in SO 2 f 2 In the atmosphere, stirring at 25°C for 2h, after the reaction, the reaction solution was filtered, and the filter cake was rinsed with acetonitrile to white to obtain 17.35g of 1,3-bis(4-methoxyphenyl)urea, the yield 91%.

[0027] Proton NMR spectrum: (500MHz, DMSO-d 6 ) (δ, ppm): 8.36 (s, 2H), 7.33 (d, J = 9.0Hz, 4H), 6.85 (d, J = 9.0Hz, 4H), 3.71 (s, 6H).

[0028] Carbon NMR spectrum: (126MHz, DMSO-d 6 )(δ, ppm): 154.31, 152.93, 132.92, 119.93, 113.94, 55.15.

[0029]

Embodiment 2

[0030] Embodiment 2: Preparation of 1,3-bis(4-methylphenyl)urea

[0031] In a 500mL single-necked flask, add 4-methylphenylhydroxamic acid (formula Ⅰ-2, R 1 =4-CH 3 ) 21.16g (140mmol), 150mL dichloromethane, 63.94g (3.0eq, 420mmol) DBU, in SO 2 f 2 In the atmosphere, stir at 25°C for 1 h, filter after the reaction, and rinse the filter cake with acetonitrile until white to obtain 15.64 g of 1,3-bis(4-methylphenyl)urea, with a yield of 93%.

[0032] Proton NMR spectrum: (500MHz, DMSO-d 6 ) (δ, ppm): 8.49 (s, 2H), 7.33 (d, J = 8.4Hz, 4H), 7.08 (d, J = 8.2Hz, 4H), 2.24 (s, 6H).

[0033] Carbon NMR spectrum: (126MHz, DMSO-d 6 )(δ, ppm): 152.62, 137.20, 130.51, 129.14, 118.24, 20.32.

[0034]

Embodiment 3

[0035] Embodiment 3: Preparation of 1,3-bis(3-chlorophenyl)urea

[0036] In a 500mL single-necked flask, add 3-chlorophenylhydroxamic acid (formula Ⅰ-3, R 1 =3-Cl) 24.02g (140mmol), 150mL acetonitrile, 18.10g (3.0eq, 420mmol) Na 2 CO 3 , at SO 2 f 2 Stir at 30° C. for 6 h in the atmosphere, filter after the reaction, and wash the filter cake with acetonitrile until white to obtain 18.11 g of 1,3-bis(3-chlorophenyl)urea with a yield of 92%.

[0037] Proton NMR spectrum: (500MHz, DMSO-d 6 ) (δ, ppm): 9.81 (s, 2H), 7.69 (s, 2H), 7.36–7.24 (m, 4H), 7.02 (dt, J = 6.7, 2.2 Hz, 2H).

[0038] Proton NMR spectrum: (126MHz, DMSO-d 6 )(δ, ppm): 152.46, 141.18, 133.18, 130.40, 121.44, 117.28, 116.36.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com