A kind of phosphogypsum concrete filled steel pipe and its preparation method

A technology of steel pipe concrete and phosphogypsum, which is applied in the field of concrete materials, can solve the problems that the expansion effect of the expansion agent is difficult to exert effectively, the hydration speed is fast, and the concrete water glue is low, so as to ensure the anti-carbonation performance, ensure the continuous effect, and avoid drying shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

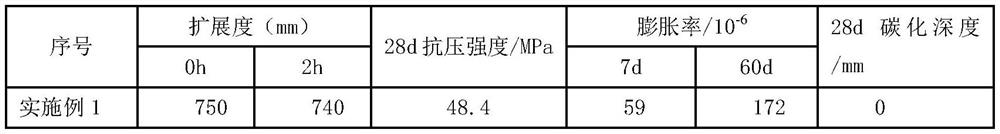

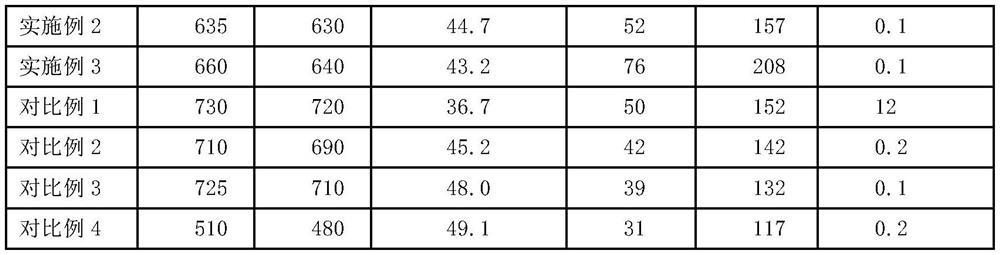

Embodiment 1

[0045] A preparation method of phosphogypsum concrete filled steel pipe, comprising the following steps:

[0046] S1: Take 45 parts of phosphogypsum, 45 parts of slag, 2 parts of cement clinker, and 8 parts of limestone by weight, mix them evenly, put them into a disc granulator to form, and obtain phosphogypsum coarse aggregate after natural curing for 28 days;

[0047]S2: Take 42 parts of phosphogypsum, 30 parts of phosphorus slag, 15 parts of slag, 3 parts of cement clinker, and 10 parts of zeolite powder by weight; first add the taken cement clinker, zeolite powder and slag into the forced mixer and stir for 30s , then add the phosphogypsum and phosphorus slag and stir for 60s to obtain phosphogypsum cement;

[0048] S3: Soak pottery sand and phosphogypsum coarse aggregate in water until saturated and dry;

[0049] S4: Weigh each raw material according to the mixing ratio: 500 parts of phosphogypsum cement, 150 parts of shale pottery sand, 550 parts of river sand, 700 par...

Embodiment 2

[0052] A preparation method of phosphogypsum concrete filled steel pipe, comprising the following steps:

[0053] S1: Take 70 parts of phosphogypsum, 20 parts of slag, 8 parts of cement clinker, and 2 parts of limestone by weight, mix them evenly, put them into a disc granulator to form, and obtain phosphogypsum coarse aggregate after natural curing for 28 days;

[0054] S2: Take 50 parts of phosphogypsum, 22 parts of phosphorus slag, 18 parts of slag, 2 parts of cement clinker, and 8 parts of zeolite powder by weight; first add the taken cement clinker, zeolite powder and slag into the forced mixer and stir for 30s , then add the taken phosphogypsum and phosphorus slag and stir for 90s to obtain phosphogypsum cement;

[0055] S3: Soak pottery sand and phosphogypsum coarse aggregate in water until saturated and dry;

[0056] S4: Weigh each raw material according to the mixing ratio: 420 parts of phosphogypsum cement, 100 parts of shale pottery sand, 500 parts of river sand, 6...

Embodiment 3

[0059] A preparation method of phosphogypsum concrete filled steel pipe, comprising the following steps:

[0060] S1: Take 34 parts of phosphogypsum, 50 parts of slag, 6 parts of cement clinker, and 10 parts of limestone by weight, mix them evenly, put them into a disc granulator to form, and obtain phosphogypsum coarse aggregate after natural curing for 28 days;

[0061] S2: Take 30 parts of phosphogypsum, 28 parts of phosphorus slag, 20 parts of slag, 7 parts of cement clinker, and 15 parts of zeolite powder by weight; first add the taken cement clinker, zeolite powder and slag into the forced mixer and stir for 30s , and then add the taken phosphogypsum and phosphorus slag and stir for 30s to obtain phosphogypsum cement;

[0062] S3: Soak pottery sand and phosphogypsum coarse aggregate in water until saturated and dry;

[0063] S4: Weigh each raw material according to the mixing ratio: 480 parts of phosphogypsum cement, 200 parts of shale pottery sand, 480 parts of river s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com