Preparation method of high-load long-acting slow-release scale inhibition particles

A high-load, long-lasting technology for chemical instruments and methods, descaling and water softening, mining wastewater treatment, etc. to achieve stable particle structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

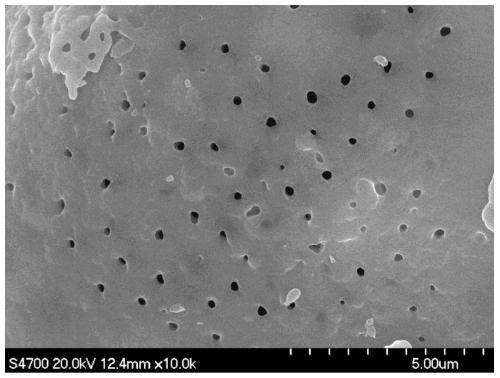

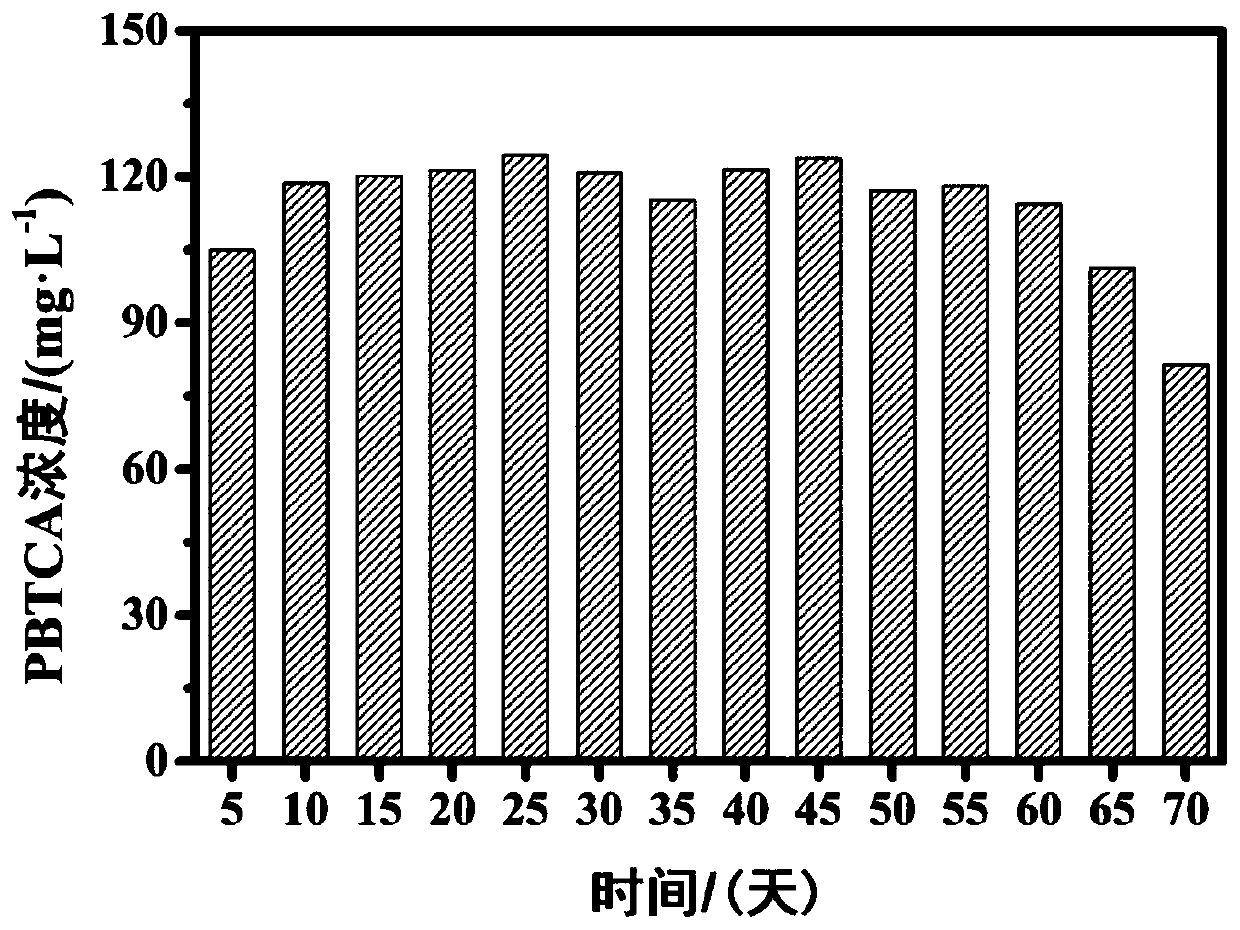

[0029] 100 parts of 50wt.% 2-phospho-1,2,4-tricarboxylic acid butane (PBTCA) aqueous solution and 10 parts of diatomaceous earth carry out vacuum negative pressure loading, the vacuum loading pressure is -0.1MPa, and kneading in the kneader 40 minutes, and then dried in a vacuum oven at 60° C. for 48 hours, and pulverized the dried solid mixture into powder.

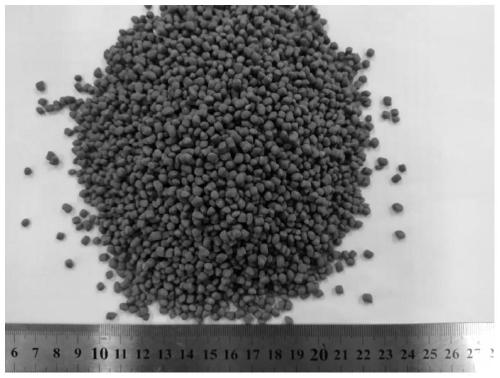

[0030] Knead 15 parts of polylactic acid and 5 parts of diethyl phthalate for 30 minutes, knead 10 parts of kaolin and 6 parts of starch for 30 minutes; mix and knead the above raw materials for 90 minutes to form an effective bond, and then extrude It is extruded in the machine and processed into round particles with a diameter of 1 to 5 mm. Spray 3 parts of 10wt.% polyvinyl alcohol, 0.5wt.% glutaraldehyde mixed solution and dry to crosslink.

Embodiment 2

[0032] 70 parts of 50wt.% hydroxyethylidene diphosphonate (HEDP) aqueous solution and 10 parts of diatomaceous earth carry out vacuum negative pressure loading, and the vacuum loading pressure is-0.3MPa, knead in kneader for 60 minutes, then in vacuum oven Dry at 70°C for 30 hours, and pulverize the dried solid mixture into powder.

[0033] Knead 18 parts of polylactic acid and 3 parts of diethyl phthalate for 30 minutes, knead 20 parts of kaolin and 15 parts of carboxymethyl cellulose for 30 minutes; mix and knead the above raw materials for 60 minutes to form an effective bond, It is extruded in a screw extruder and processed into round particles with a diameter of 1-5 mm. Spray 3 parts of 10wt.% polyvinyl alcohol, 0.5wt.% glutaraldehyde mixed solution and dry to crosslink.

Embodiment 3

[0035] 90 parts of 50wt.% diaminetetramethylene phosphonic acid (HDTMPA) aqueous solution and 18 parts of diatomaceous earth carry out vacuum negative pressure loading, vacuum loading pressure is-0.2MPa, knead in the kneader for 50 minutes, then in the vacuum oven Dry at 75°C for 24 hours, and crush the dried solid mixture into powder.

[0036] Mix 25 parts of polylactic acid and 6 parts of diethyl phthalate evenly, mix 15 parts of quartz stone with 20 parts of gelatin; mix and knead the above raw materials for 60 minutes to form an effective bond, in the screw extruder Extruded into round particles with a diameter of 1 to 5 mm. Spray 3 parts of 10wt.% polyvinyl alcohol, 0.5wt.% glutaraldehyde mixed solution and dry to crosslink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com