Carbon fiber sandwich composite material and preparation method and application thereof

A composite material and carbon fiber technology, applied in chemical instruments and methods, synthetic resin layered products, railway car bodies, etc., can solve problems such as the inability to meet the use requirements of high-speed rail car bodies, and achieve improved electromagnetic shielding efficiency and good flame retardant performance. , The effect of excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

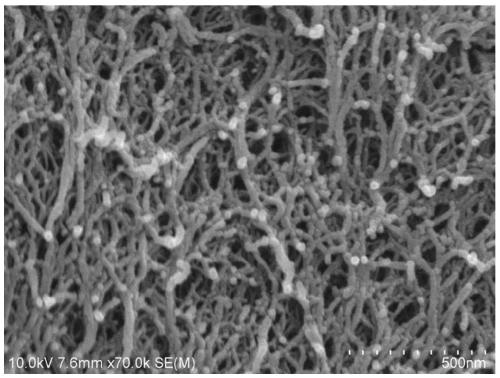

[0055] This embodiment provides a method for preparing a carbon fiber sandwich composite material, comprising:

[0056] S1. Fabrication of polyimide airgel core material

[0057] (1) Under nitrogen atmosphere, add 158g of 4,4-diaminodiphenyl ether into 3300mL of N-methylpyrrolidone, keep stirring until it is completely dissolved, then add 240g of 3,3,4,4-biphenyl Tetracarboxylic dianhydride, continue to stir for a certain period of time until the polycondensation reaction is complete after the reactant becomes transparent, and obtain a fully reacted polyamic acid solution;

[0058] (2) Add a moderate amount of 615mL acetic anhydride and 525mL pyridine to the polyamic acid solution, and mix well to completely polyimide the polyamic acid solution.

[0059] (3) Pour the product polyimide solution into the mold, wait for its gel and age at room temperature for 1 day, soak the aged gel in 5000mL absolute ethanol for sufficient solvent replacement, and soak for 3 days in total, eve...

Embodiment 2

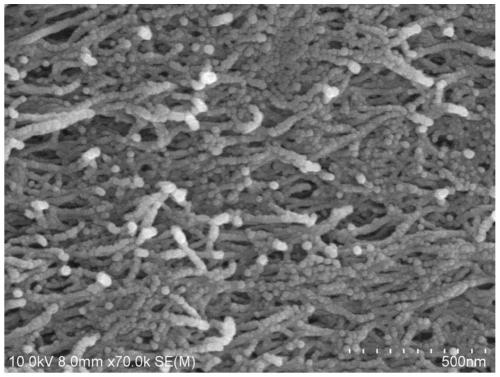

[0081] This embodiment provides a method for preparing a carbon fiber sandwich composite material, comprising:

[0082] S1. Fabrication of polyimide airgel core material

[0083] (1) Under nitrogen atmosphere, add 179g of 2,2-dimethylbenzidine into 3600mL of N-methylpyrrolidone, keep stirring until it is completely dissolved, then add 269g of 3,3,4,4-benzophenone Tetraacid dianhydride, after the reactants become transparent, continue to stir for a certain period of time until the polycondensation reaction is complete, and a fully reacted polyamic acid solution is obtained.

[0084] (2) Add a moderate amount of 615mL acetic anhydride and 525mL pyridine to the polyamic acid solution, and mix well to completely polyimide the polyamic acid solution.

[0085] (3) Pour the product polyimide solution into the mold, wait for it to gel and age at room temperature for 1 day, then soak the aged gel in 5000mL absolute ethanol for sufficient solvent replacement, and soak for 3 days in tot...

Embodiment 3

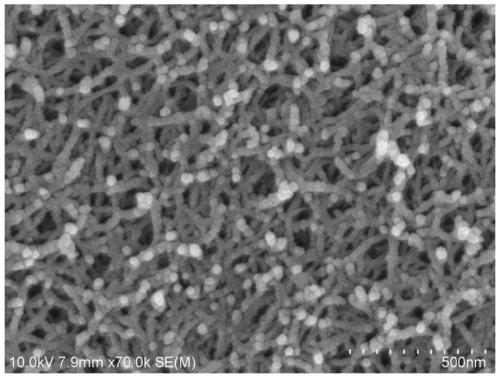

[0105] This embodiment provides a method for preparing a carbon fiber sandwich composite material, comprising:

[0106] S1. Fabrication of polyimide airgel core material

[0107] (1) Under nitrogen atmosphere, add 179g of 2,2-dimethylbenzidine into 3600mL of N-methylpyrrolidone, keep stirring until it is completely dissolved, then add 269g of 3,3,4,4-benzophenone Tetraacid dianhydride, after the reactants become transparent, continue to stir for a certain period of time until the polycondensation reaction is complete, and a fully reacted polyamic acid solution is obtained.

[0108] (2) Add a moderate amount of 615mL acetic anhydride and 525mL pyridine to the polyamic acid solution, and mix well to completely polyimide the polyamic acid solution.

[0109] (3) Pour the product polyimide solution into the mold, wait for it to gel and age at room temperature for 1 day, then soak the aged gel in 5000mL absolute ethanol for sufficient solvent replacement, and soak for 3 days in total...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com