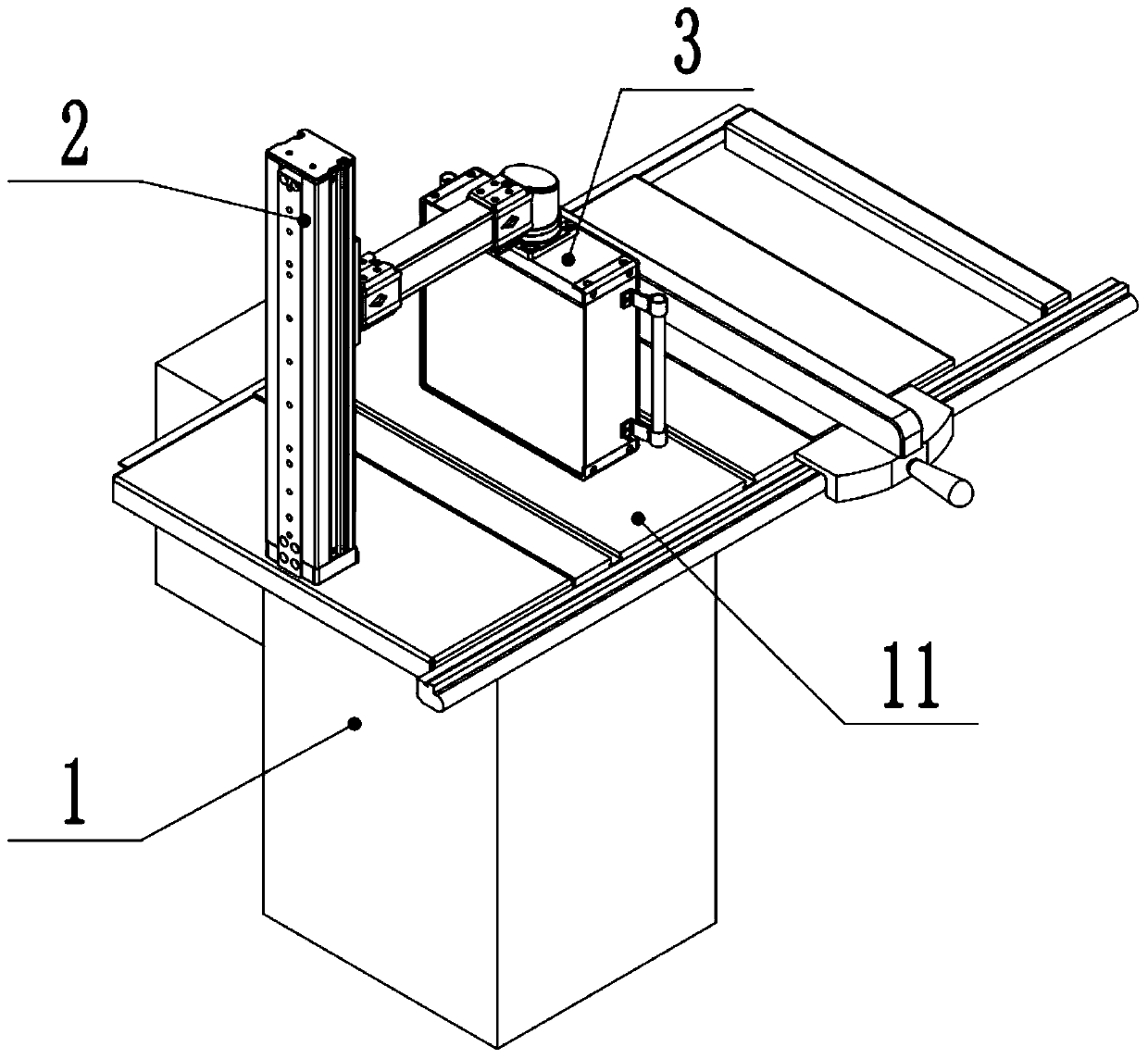

Safe-to-use sliding table saw and safety use method

A sliding table saw, a safe technology, applied in the direction of cleaning methods using gas flow, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as misoperation, danger to the lives of workers, wood burns, etc., to increase the contact area , improve the mixing effect, avoid the effect of humidification area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

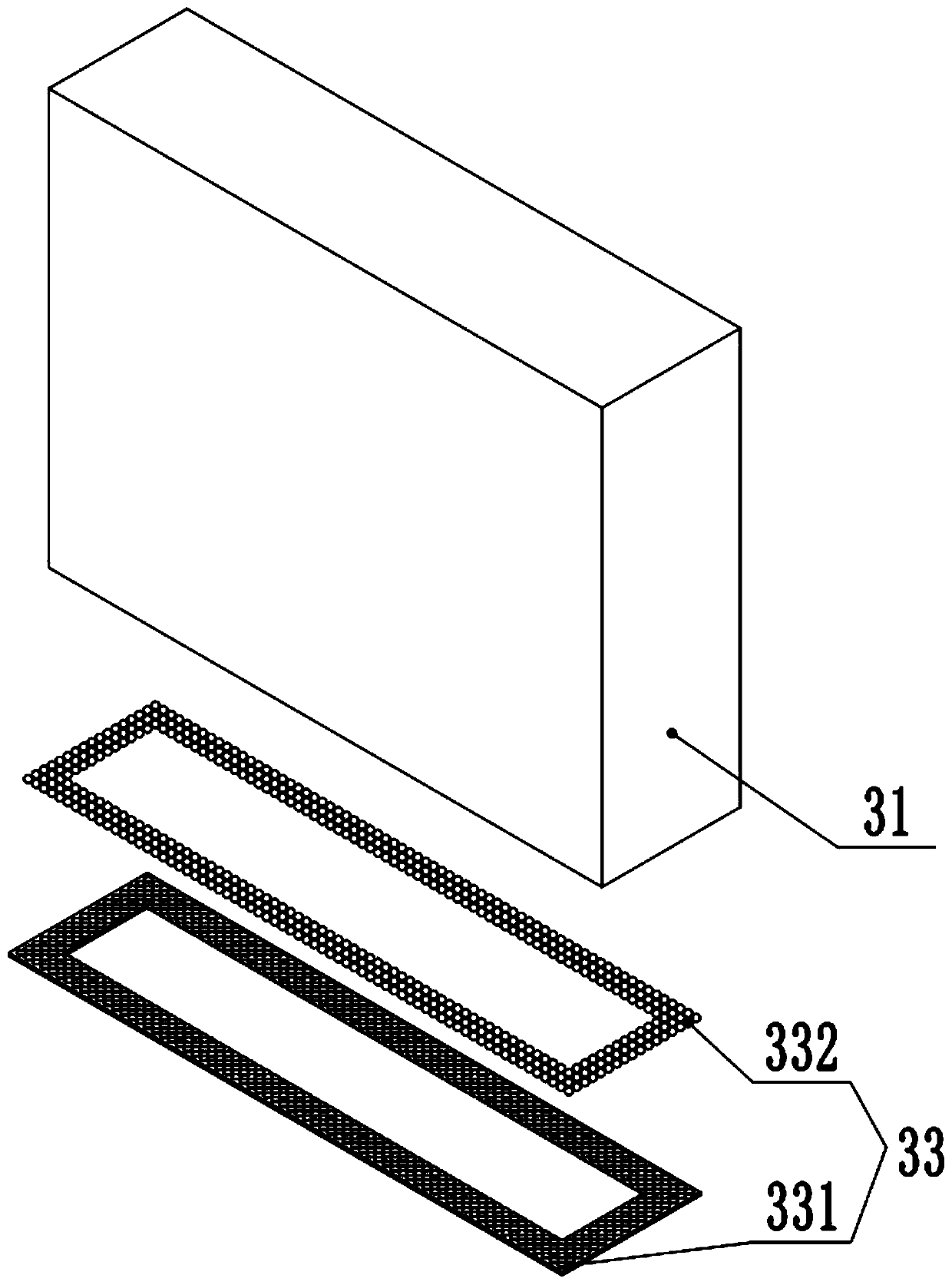

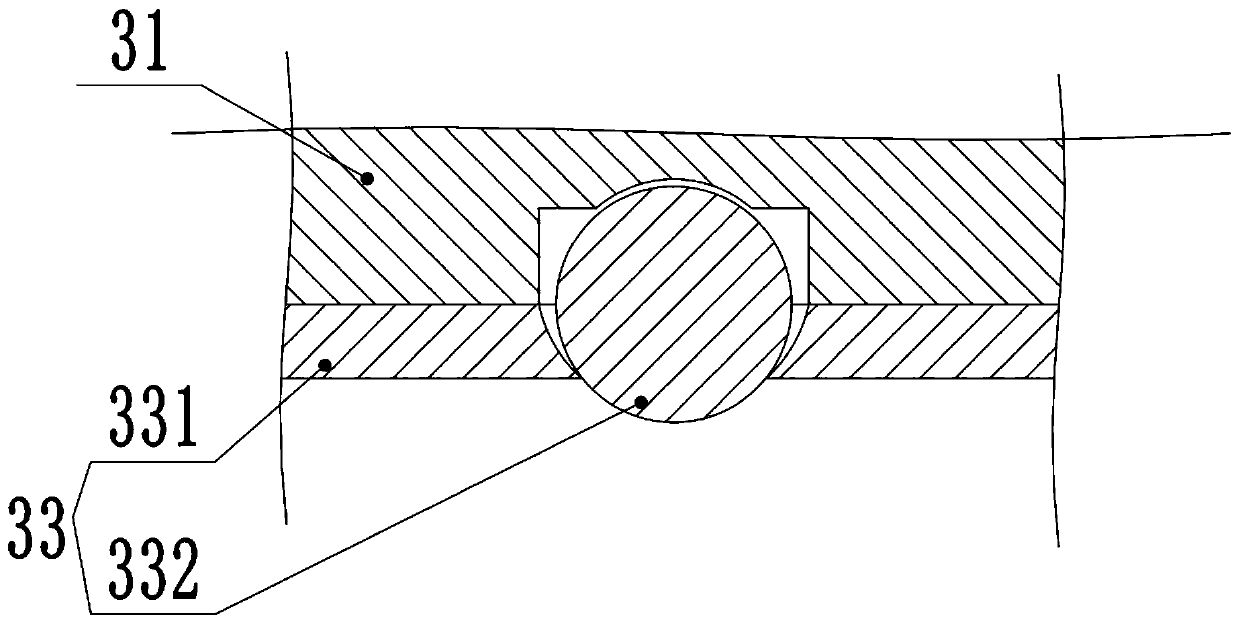

[0057] According to the research of the applicant, it is found that the existing sliding table saw has serious heat generation when working for a long time, which will cause burns to the wood and affect the subsequent processing of the wood, especially when the saw blade is worn out, the heat is more serious. The friction between wood and sawdust is easy to cause fire. The existing technical solution is only to set a receiving port in the protective cover to absorb the sawdust, and does not fundamentally solve the problem of saw blade heating; The resistance generated by the abutment affects the feeding process of the wood and increases the physical labor of the staff. The technical solution adopted is to reserve a large gap between the protective cover and the wood. Although this technical solution reduces the number of workers However, the wind force of the material receiving port has been used in the protective cover to suck away the sawdust, and the high-speed rotation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com