Spherical surface grinding device for ball valve cores

A spherical surface grinding and ball core technology, which is applied to grinding drive devices, grinding/polishing safety devices, spherical surface grinding machines, etc., can solve the problems of low efficiency, inability to process, troublesome use, etc., to achieve convenient use and improve production. Efficiency, quick adjustment of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

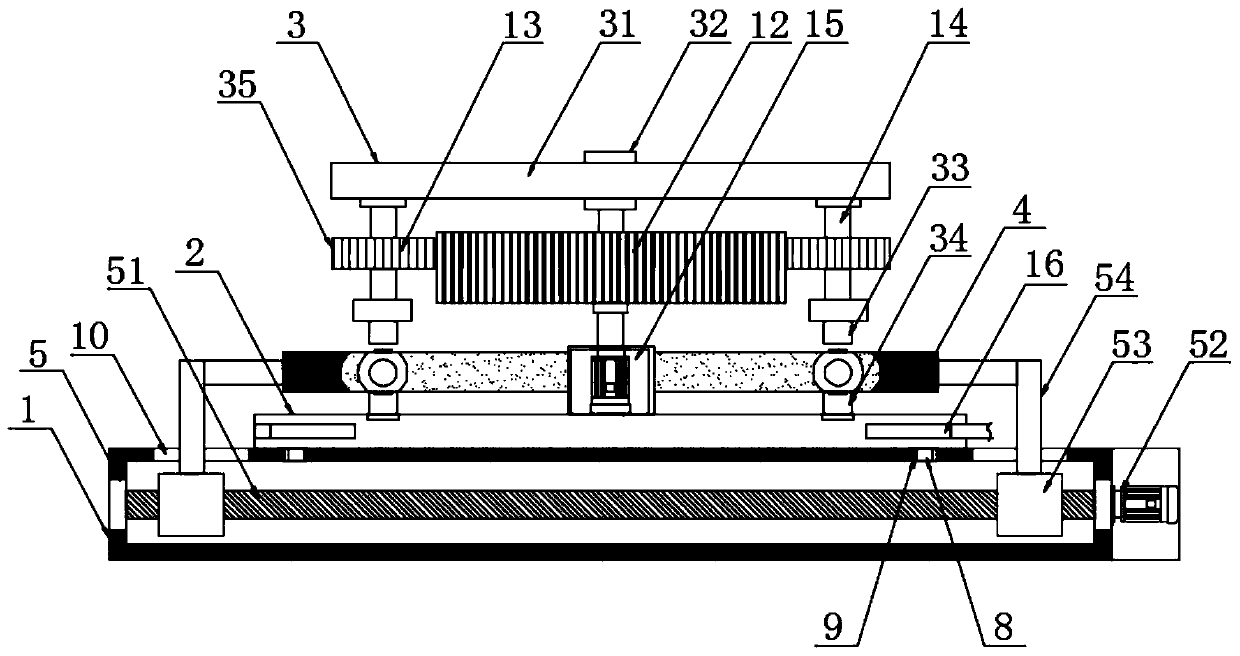

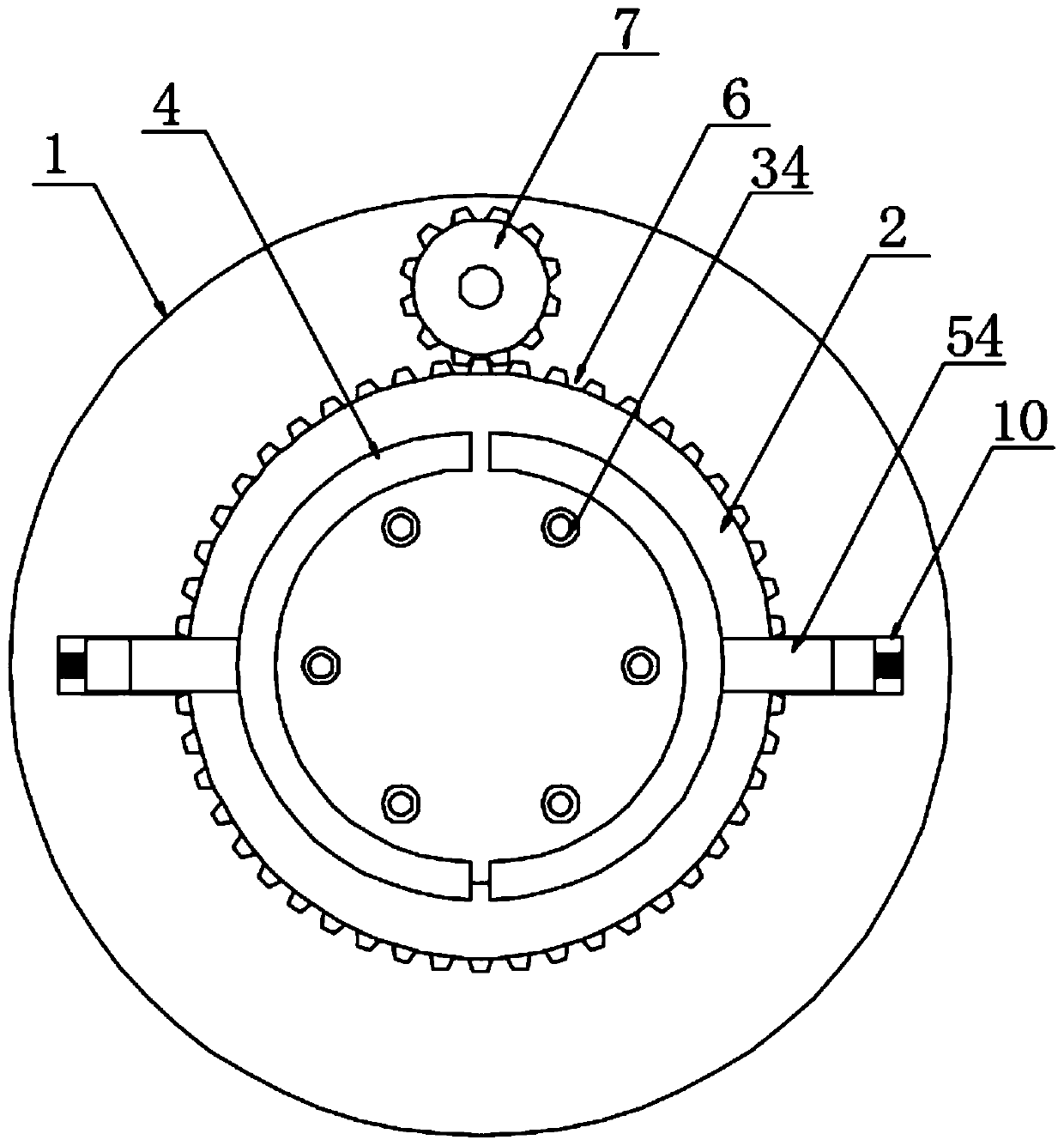

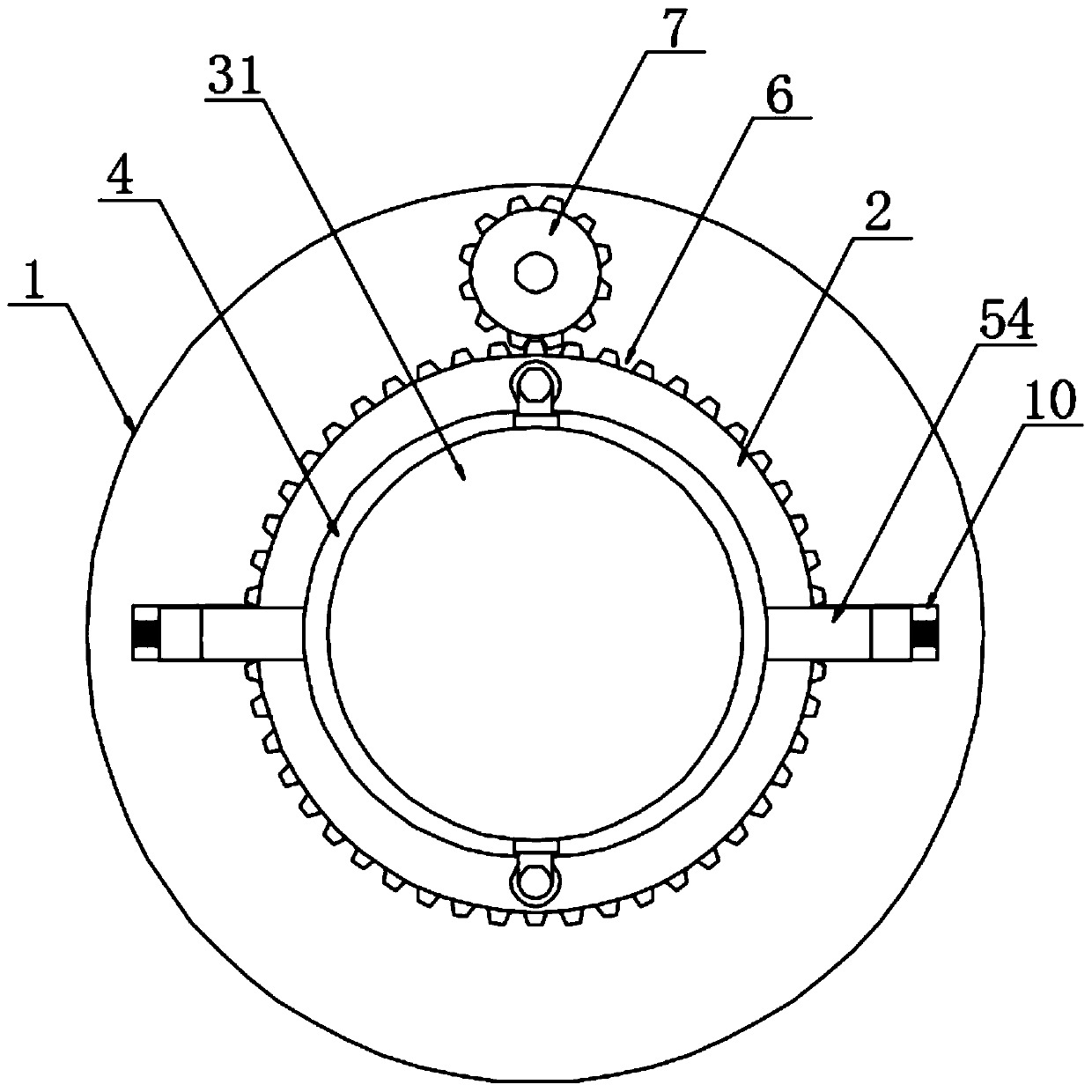

[0031] Refer to the attached Figure 1-5 In this embodiment, a spherical surface grinding device for a ball valve core includes a workbench 1, a rotary table 2 is provided on the top of the worktable 1, and a multi-ball core clamping mechanism 3 is provided on the top of the rotary table 2. The two sides of the multi-core clamping mechanism 3 are respectively equipped with grinding outer plates 4, and the two grinding outer plates 4 are driven by the reciprocating mechanism 5 to perform reciprocating linear motion, and are used for grinding the ball fixed by the multi-ball core clamping mechanism 3. Spherical core surface, the outer wall of the rotary table 2 is provided with a tooth groove 6, and the rear side of the rotary table 2 is provided with a driving gear 7 meshing with the tooth groove 6, and the driving gear 7 is driven by a servo motor;

[0032] The multi-core clamping mechanism 3 includes a lifting table 31, an electric telescopic rod 32, an upper clamp 33, a lowe...

Embodiment 2

[0046] Refer to the attached Figure 6-7 , the inside of the turntable 2 is provided with an exhaust cavity 16, the slot 11 on the lower fixture 34 runs through the lower fixture 34 and communicates with the exhaust cavity 16, and the outer wall of the turntable 2 is provided with a plurality of exhaust holes 17 , the exhaust hole 17 communicates with the exhaust cavity 16, the exhaust cavity 16 is arranged in a ring shape, one end of the exhaust cavity 16 is connected to the exhaust pipe 18, and one end of the exhaust pipe 18 runs through the rotary table 2 and is connected by a bellows Vacuum cleaner.

[0047] The specific implementation scene is: the present invention sets up the embedded groove 11 connected with the air suction chamber 16 on the lower fixture 34, the vacuum cleaner works, and the air inside the air suction chamber 16 is extracted through the bellows and the air suction pipe 18, and a negative pressure is formed in the air suction chamber 16 , when the sph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com