Numerical control machine tool

A technology of CNC machine tools and controllers, applied in the field of CNC machine tools, can solve the problems of not having the ability to automatically adjust the level state, etc., and achieve the effects of reliable connection, convenient detection and maintenance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

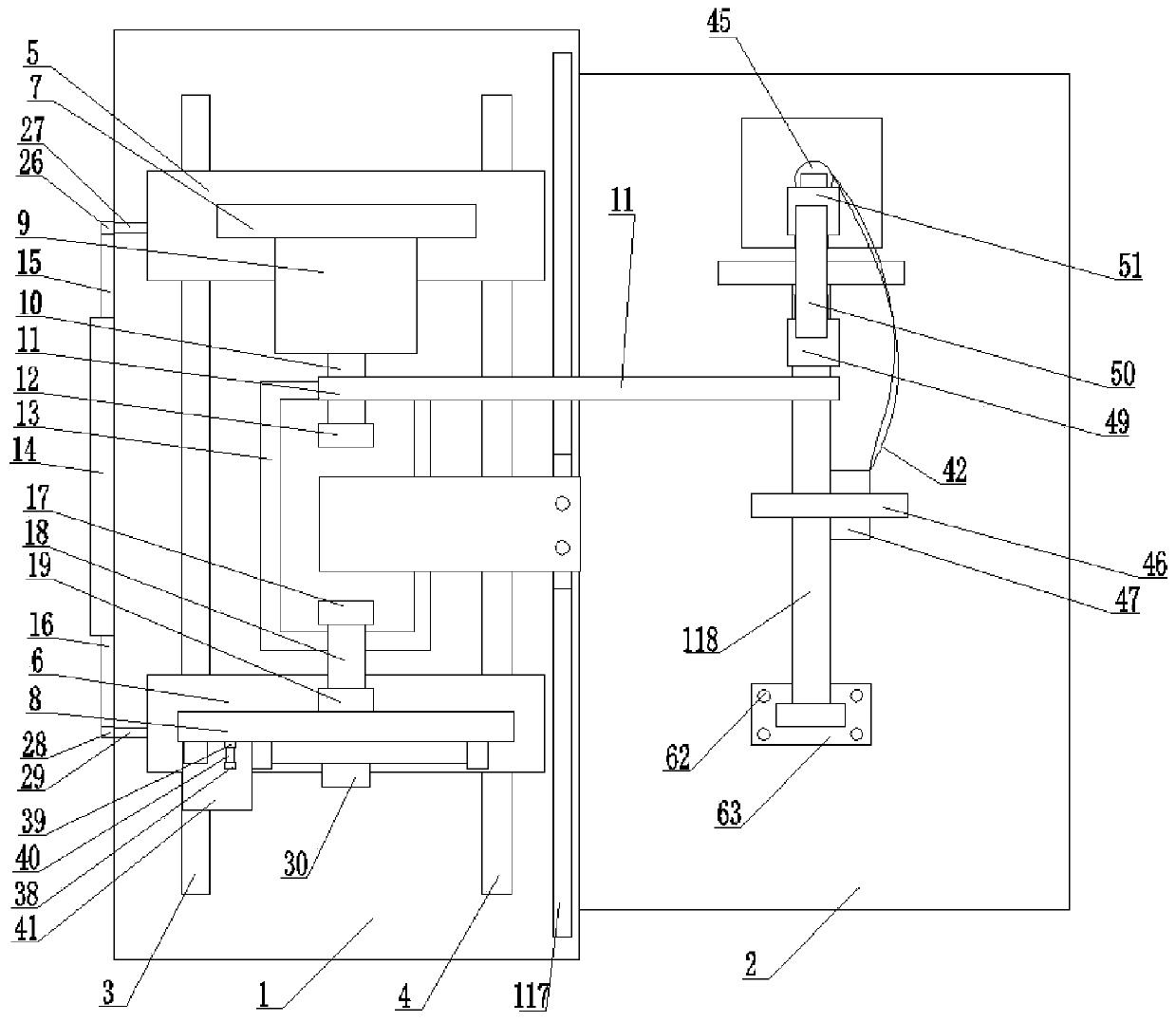

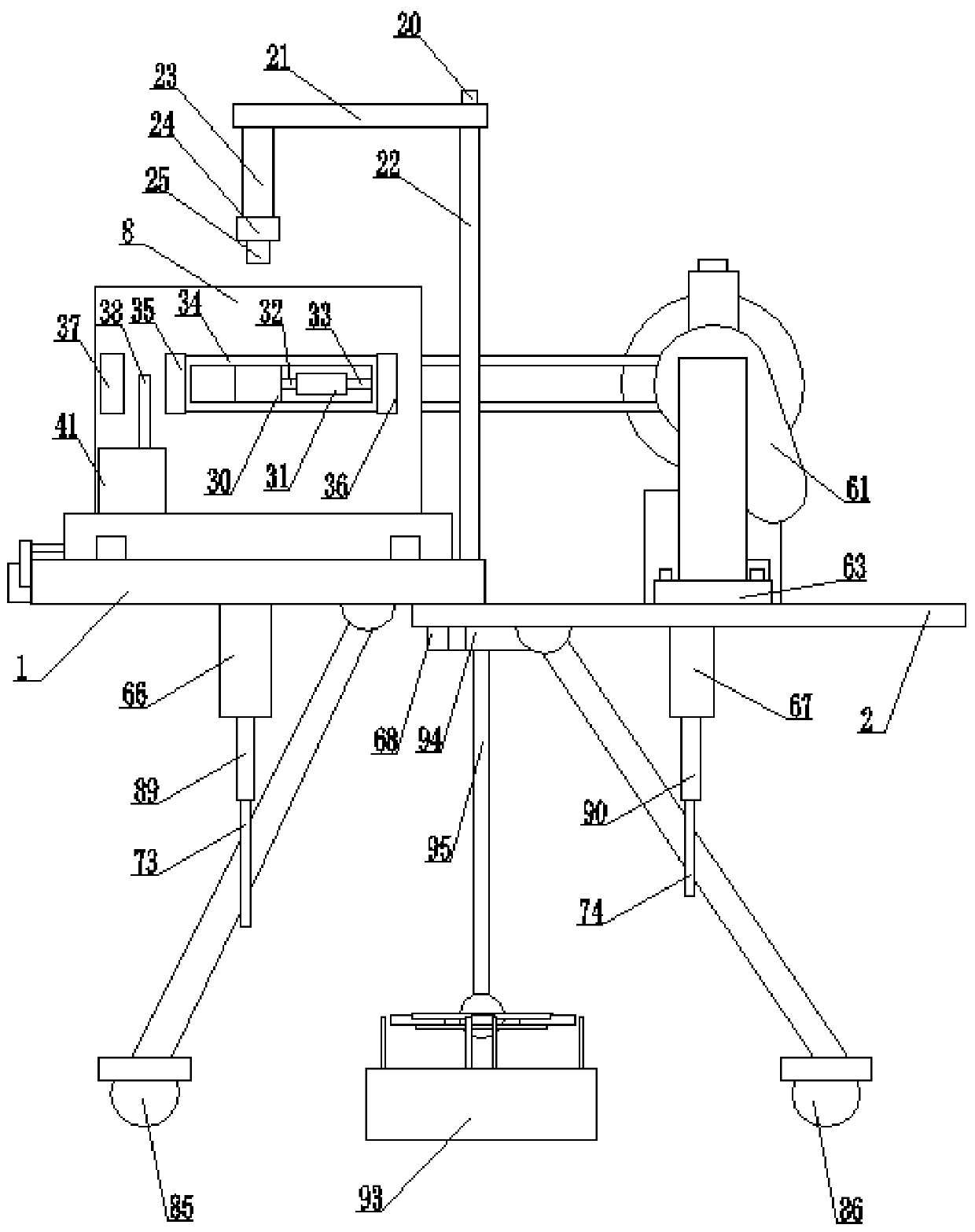

[0031] The present invention is described in detail below in conjunction with accompanying drawing:

[0032] refer to Figure 1 to Figure 9 , a kind of numerically controlled machine tool provided by the present invention comprises main board 1, sub-board 2, balance control box 93, described main board 1, sub-board 2 are fixedly connected by the third series bolt group 68, the top surface of described main board 1 The left and right sides of the left and right sides are respectively provided with a left guide rail 3 and a right guide rail 4, and the front and rear ends of the left guide rail 3 and the right guide rail 4 are respectively provided with a front movable seat 5 and a rear movable seat 6. The top surfaces of the movable seat 5 and the rear movable seat 6 are respectively provided with a front wall 7 and a rear wall 8, the rear side of the front wall 7 is provided with a motor 9, and the power output end of the motor 9 is provided with a power Shaft 10, the rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com