Integral forming process of boiler header pipe seat

A technology of integral molding and boiler header, which is applied in the field of molding process of boiler header tube seat, can solve the problems of high labor intensity, low degree of automation, low efficiency, etc., and achieve improved stability and reliability, high degree of automation, The effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

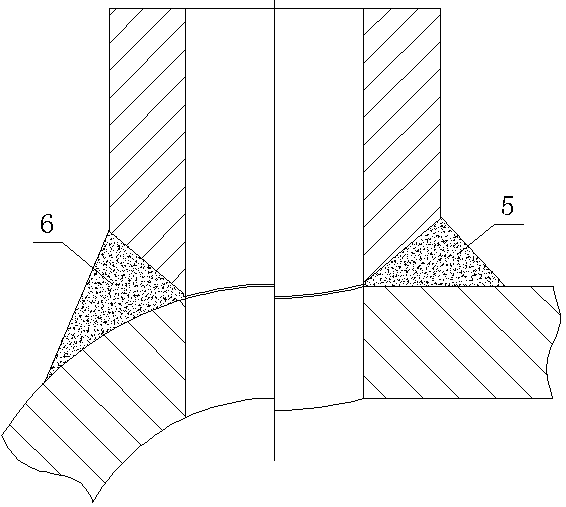

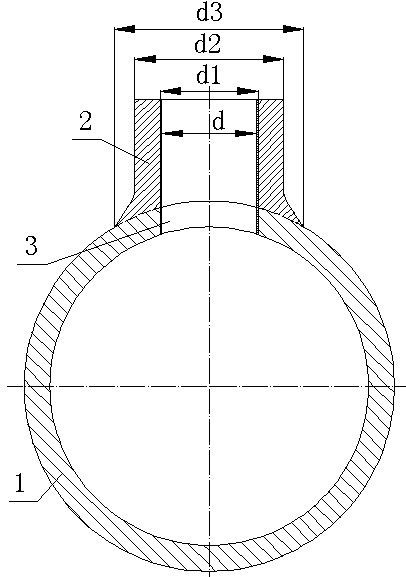

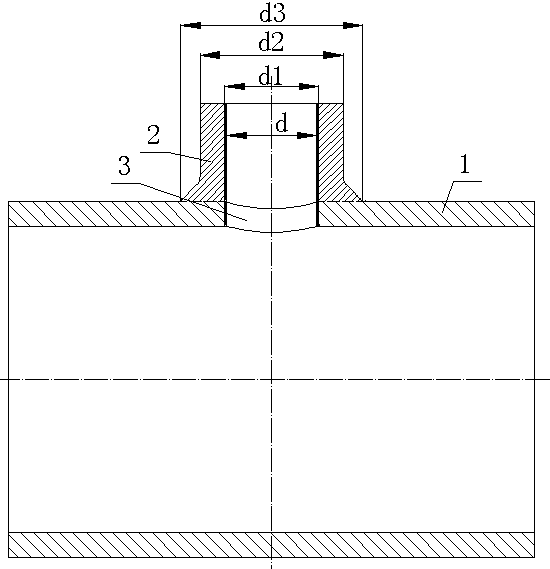

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail.

[0015] Take a project as an example, such as figure 2 , image 3 As shown, the material of the boiler header shell 1 is 12Cr1MoVG, the specification is φ363×50, the tube seat 2 is arranged on the tube body 1, the material is 12Cr1MoVG, and the specification is φ216×35; Intersection, the axial direction of the tube base 2 passes through the center of the header cylinder 1, the distance between the axis of the tube base 2 and the diameter centerline of the cylinder 1 is 0mm; the angle between the axis of the tube base 2 and the axis of the cylinder 1 is 0°; The included angle between the axis of seat 2 and the diameter centerline of cylinder 1 is 0°; the overall molding process of boiler header tube seat in this embodiment includes the following steps: A) drawing the inner diameter line of tube hole 3 on cylinder 1 and The inner diameter line and outer diameter line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com