Automatic spraying assembly line based on metal covering protective layer and capable of transversely moving and rotatably swinging

An automatic spraying and protective layer technology, applied in the field of assembly line, can solve the problems of heavy metal finished product quality, bonded paint surface blocks, metal surface flatness, potholes, etc., to improve effective recycling operations, ensure paint surface density, improve The effect of process precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

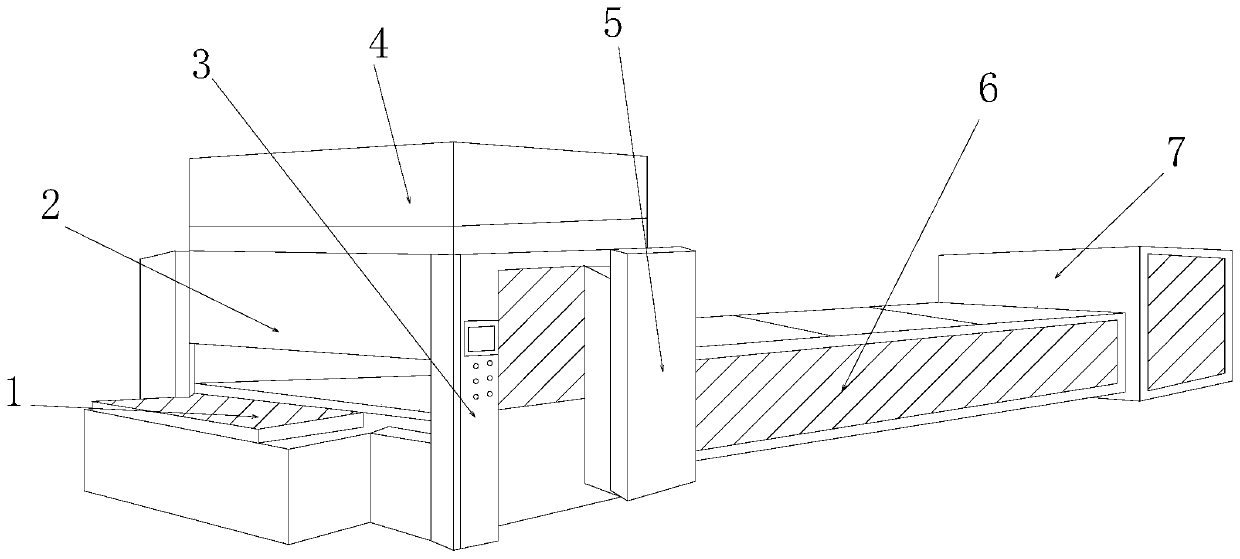

[0031] see Figure 1-Figure 6, the present invention provides an automatic spraying line based on a metal-covered protective layer and a traversing and swinging pendulum. Groove 4, power distribution box 5, conveyor belt board box 6, finished product storage cabinet 7, the traversing and swinging rack 2 is nested under the bottom of the shaft wheel top cover groove 4 and communicates with each other, and the feeding stage 1 is installed on the lower left corner of the traversing and swinging frame 2, the man-machine interface board 3 is close to the front side of the traversing and swinging frame 2, the man-machine interface board 3 is electrically connected with the power distribution box 5 and Being on the same vertical plane, the traversing swing frame 2 and the finished product storage cabinet 7 are respectively nested on the left and right sides of the conveyor belt crate 6, and the conveyor belt crate 6 is on the same level as the loading platform 1 Above, the traversin...

Embodiment 2

[0038] see Figure 1-Figure 6 , the present invention provides a kind of automatic spraying assembly line based on the swaying and pendulum of the metal covering protective layer, other aspects are the same as embodiment 1, the difference is:

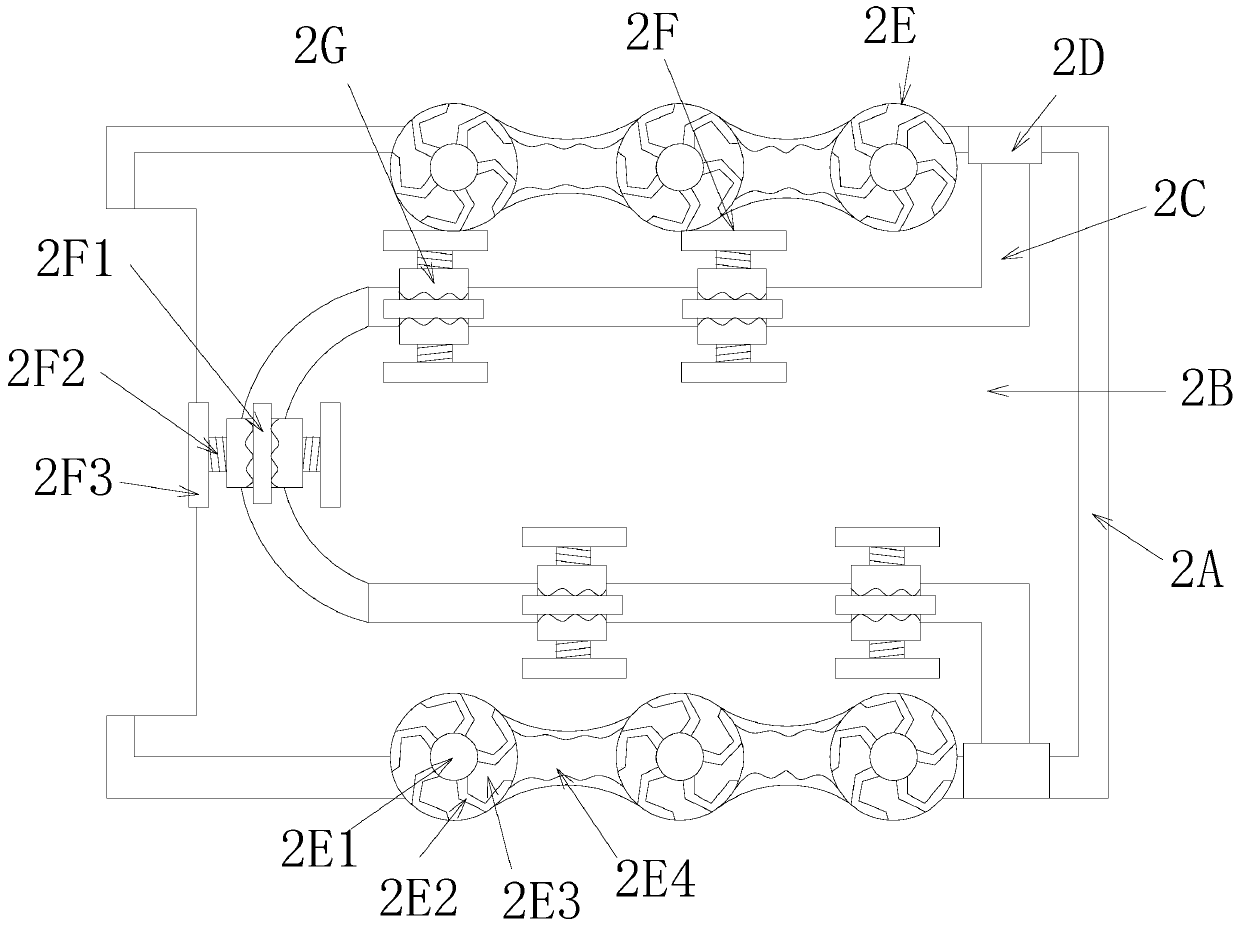

[0039] see figure 2 The hoisting clamp seat 2F is composed of a spacer plate 2F1, a dish ring threaded post 2F2, and a hoisting splint 2F3. There are two dish ring threaded posts 2F2 which are respectively inserted into the left and right sides of the spacer plate 2F1. The hoisting splint 2F3 and the dish ring threaded column 2F2 are nested into one body and are perpendicular to each other. The spacer plate 2F1 is plugged between the two hoisting splints 2F3 to form the spacing limit erection effect of the metal plate front and rear paint spraying racks, ensuring up and down The brush is in place in one step, so that the front and rear sides of the metal are sprayed at the same time and the operation is efficient.

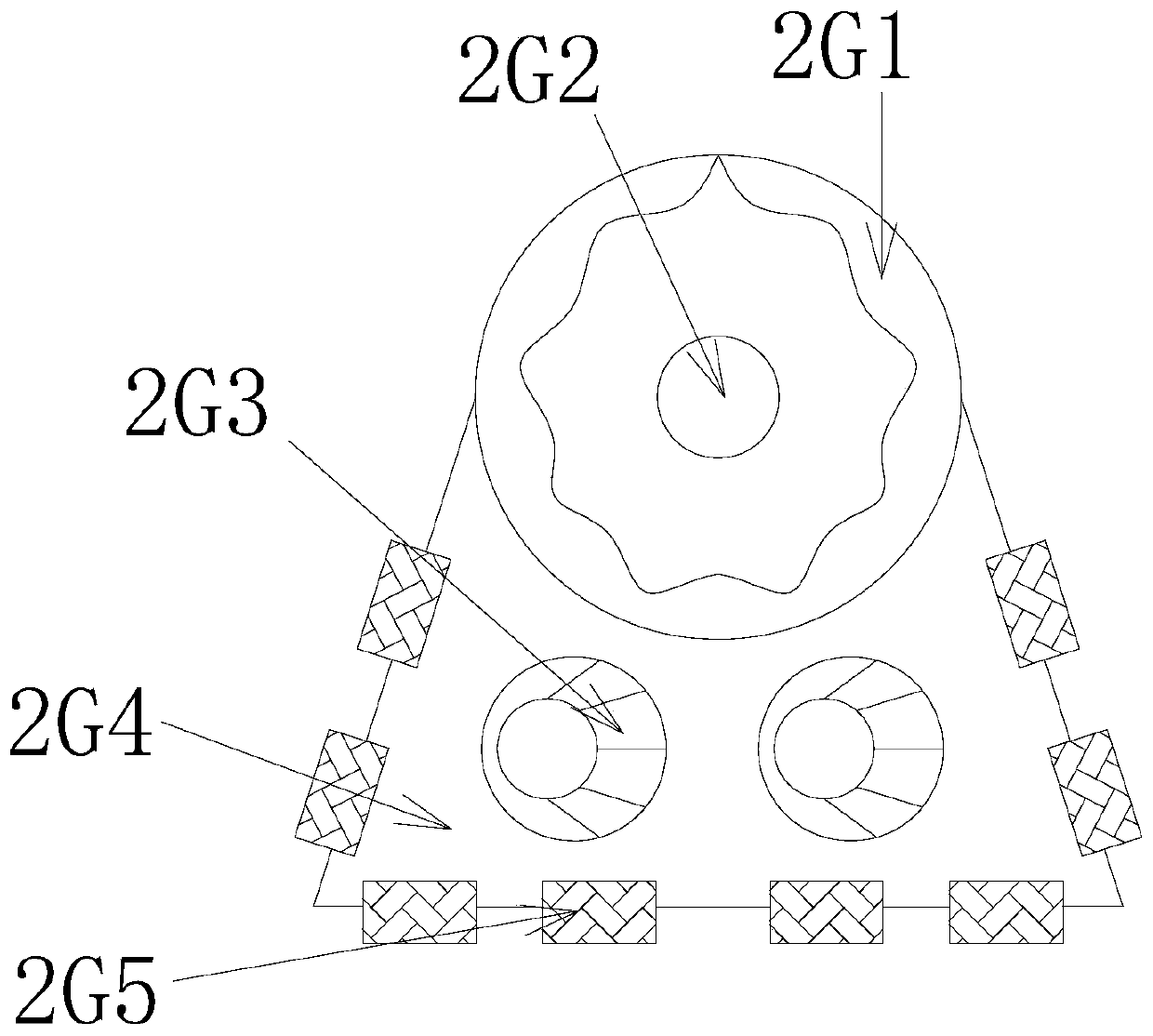

[0040] see Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com