Niobite type manganese-niobium-based SCR denitration catalyst and preparation method thereof

A denitration catalyst and niobium iron ore technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of unknown N2 selectivity, inability to achieve industrial applications, etc., and achieve good resistance to H2O and SO2 poisoning. performance, good denitrification performance, the effect of reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

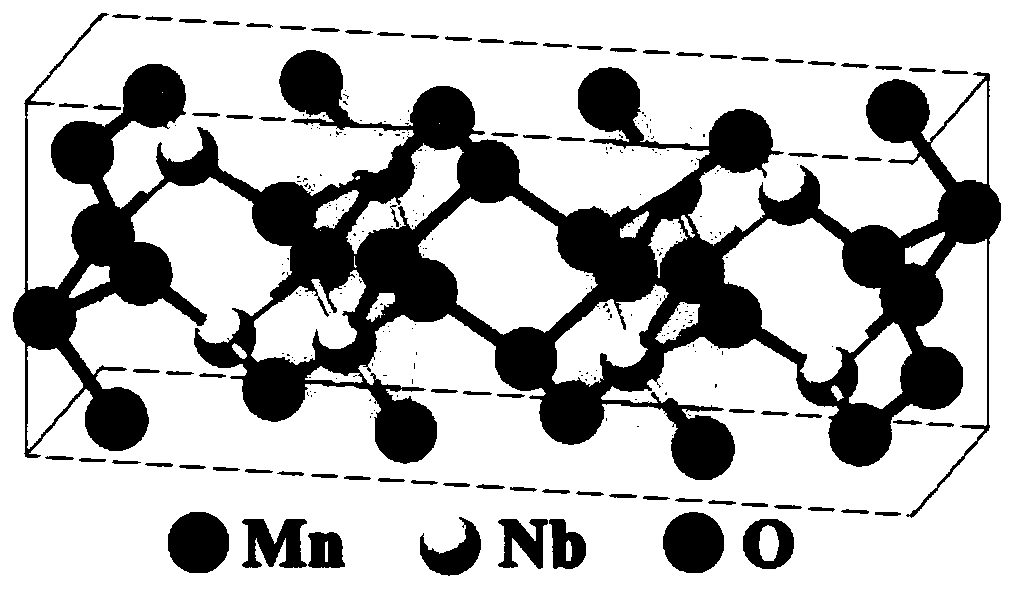

[0027] A niobite-type manganese-niobium-based SCR denitrification catalyst and a preparation method thereof, wherein the catalyst includes an active component, a carrier and an auxiliary agent, and the active component comprises a niobite-type structure of MnNb 2 o 6 , MnO x , NbO x ; The carrier is TiO 2 ; The auxiliary agent is methyl cellulose, glycerin and tung oil;

[0028] The catalyst active component is denoted as Mn x Nb 1-x o z ; Among the active components, x=0.33; In terms of mass fraction, the active components in the catalyst account for 10 parts, the carrier accounts for 88.1 parts, the methyl cellulose accounts for 1 part, and glycerin accounts for 1 part. 0.3 parts, tung oil accounts for 0.6 parts;

[0029] Described preparation method comprises the following steps:

[0030] (1) Active component deployment: the precursors of Mn and Nb are mixed with deionized water in proportion to obtain a mixture;

[0031] (2) Loading and mixing: the mixture, carrie...

Embodiment example 2

[0039] A niobite-type manganese-niobium-based SCR denitrification catalyst and a preparation method thereof, wherein the catalyst includes an active component, a carrier and an auxiliary agent, and the active component comprises a niobite-type structure of MnNb 2 o 6 , MnO x , NbO x , oxide doped with Fe; the carrier is TiO 2 ; The auxiliary agent is methyl cellulose, glycerin and tung oil;

[0040] The catalyst active component is denoted as Mn x Nb 1-x-y m y o z , M represents Fe; x=0.25, y=0.1 in the described active component; In terms of mass fraction, the active component in the catalyst accounts for 18 parts, the carrier accounts for 80 parts, and the methyl Cellulose accounts for 1 part, glycerin accounts for 0.5 parts, and tung oil accounts for 0.5 parts;

[0041] Described preparation method comprises the following steps:

[0042] (1) Active component deployment: Mn, Nb, Fe precursors are mixed with deionized water in proportion to obtain a mixture;

[0043...

Embodiment example 3

[0052] A niobite-type manganese-niobium-based SCR denitrification catalyst and a preparation method thereof, wherein the catalyst includes an active component, a carrier and an auxiliary agent, and the active component comprises a niobite-type structure of MnNb 2 o 6 , MnO x , NbO x , an oxide doped with Co; the support is TiO 2 ; The auxiliary agent is methyl cellulose, glycerin and tung oil;

[0053] The catalyst active component is denoted as Mn x Nb 1-x-y m y o z , M represents Co; x=0.26, y=0.95 in the described active component; In terms of mass fraction, the active component in the catalyst accounts for 17 parts, the carrier accounts for 80 parts, and the methyl Cellulose accounts for 2 parts, glycerin accounts for 0.4 parts, and tung oil accounts for 0.6 parts;

[0054] Described preparation method comprises the following steps:

[0055] (1) Active component deployment: the precursors of Mn, Nb, and Co are mixed with deionized water in proportion to obtain a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com