A kind of processing method of ptfe hollow fiber membrane

A processing method, PTFE technology, applied in the direction of chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high temperature resistance that cannot meet the use requirements of membrane filaments, secondary damage to membrane filaments, limited organic materials, etc., to achieve Guaranteed flexibility and chemical stability, less destructive effect, and small heating zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

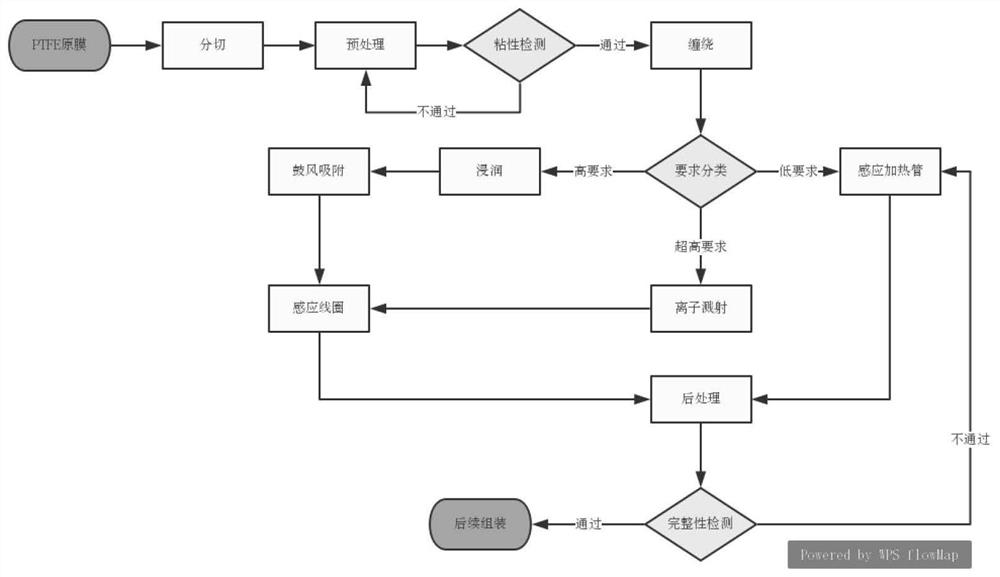

Method used

Image

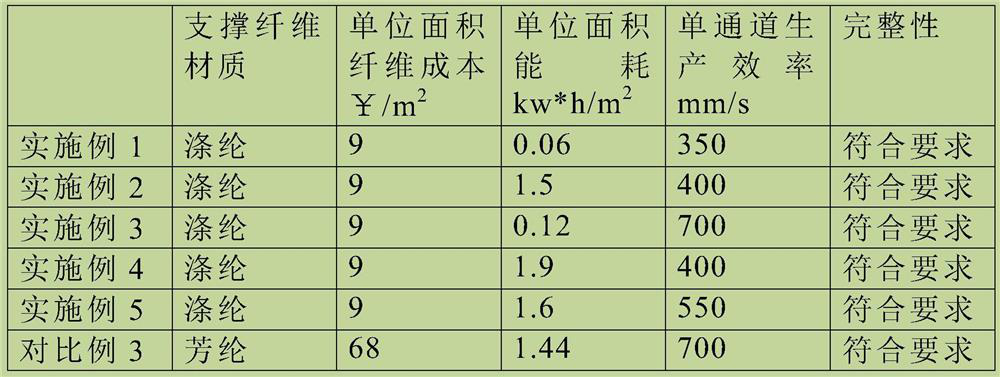

Examples

Embodiment 1

[0048] In the present embodiment, the processing method of the PTFE hollow fiber membrane comprises the following steps:

[0049] (1) Pretreatment: Use ethanol and isopropanol to soak the PTFE original film, and then perform blast heating treatment on the soaked PTFE original film. The temperature of the blast heating treatment is 50°C, and the heating time is 6h. The viscosity of the PTFE membrane after the blast heating treatment is tested. If the viscosity index is qualified, it will go to the next process. If the viscosity index is unqualified, the soaking treatment will be performed again.

[0050] (2) The PTFE original film that has passed the viscosity test after pretreatment is cut into strips and wrapped around a polyester hollow braided fiber tube to form a long fiber film filament with a diameter of 2.1 mm.

[0051] (3) in the circulating blast chamber, insert the carbon powder rod into the isopropanol solvent, so that the carbon powder is dispersed in the isopropan...

Embodiment 2

[0056] In the present embodiment, the processing method of the PTFE hollow fiber membrane comprises the following steps:

[0057] (1) Pretreatment: Use ethanol and isopropanol to soak the PTFE original film, and then perform blast heating treatment on the soaked PTFE original film. The temperature of the blast heating treatment is 50°C, and the heating time is 6h. The viscosity of the PTFE membrane after the blast heating treatment is tested. If the viscosity index is qualified, it will go to the next process. If the viscosity index is unqualified, the soaking treatment will be performed again.

[0058] (2) The PTFE original membrane that has passed the viscosity test after pretreatment is wrapped into strips and wrapped around the polyester hollow braided fiber tube to form long fiber membrane filaments with a diameter of 2.1 mm.

[0059] (3) The conductive material silver is attached to the surface of the film wire by ion sputtering in a vacuum environment. The process param...

Embodiment 3

[0062] In the present embodiment, the processing method of the PTFE hollow fiber membrane comprises the following steps:

[0063] (1) Pretreatment: Use ethanol and isopropanol to soak the PTFE original film, and then perform blast heating treatment on the soaked PTFE original film. The temperature of the blast heating treatment is 50°C, and the heating time is 6h. The viscosity of the PTFE membrane after the blast heating treatment is tested. If the viscosity index is qualified, it will go to the next process. If the viscosity index is unqualified, the soaking treatment will be performed again.

[0064] (2) The PTFE original film that has passed the viscosity test after pretreatment is cut into strips and wrapped around a polyester hollow braided fiber tube to form a long fiber film filament with a diameter of 2.1 mm.

[0065] (3) Directly pass the membrane wire through a graphite hollow tube heated by a high-frequency induction coil at a speed of 300mm / s. The induction heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com