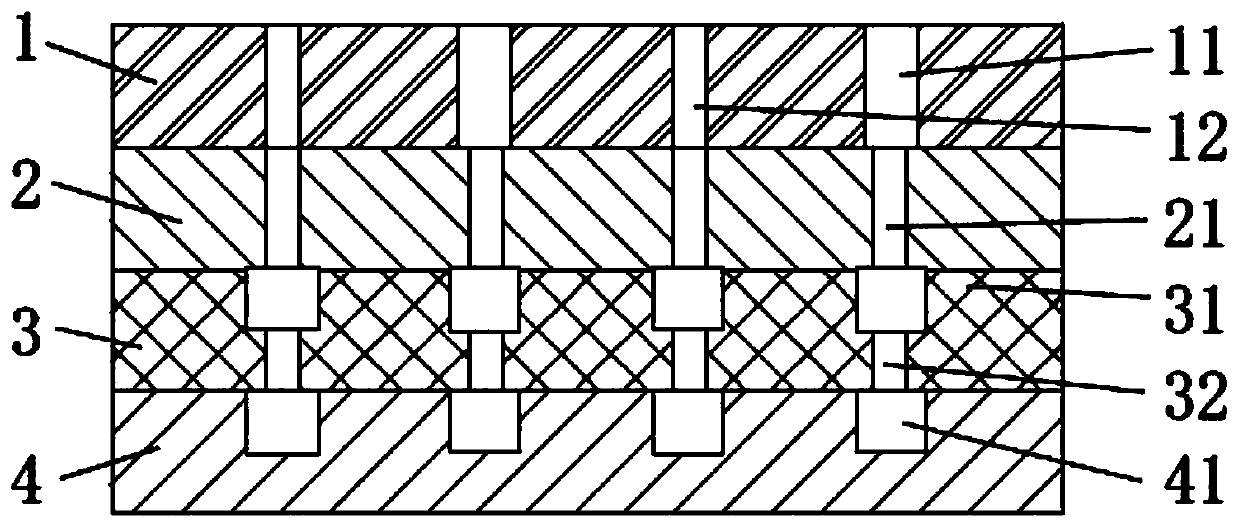

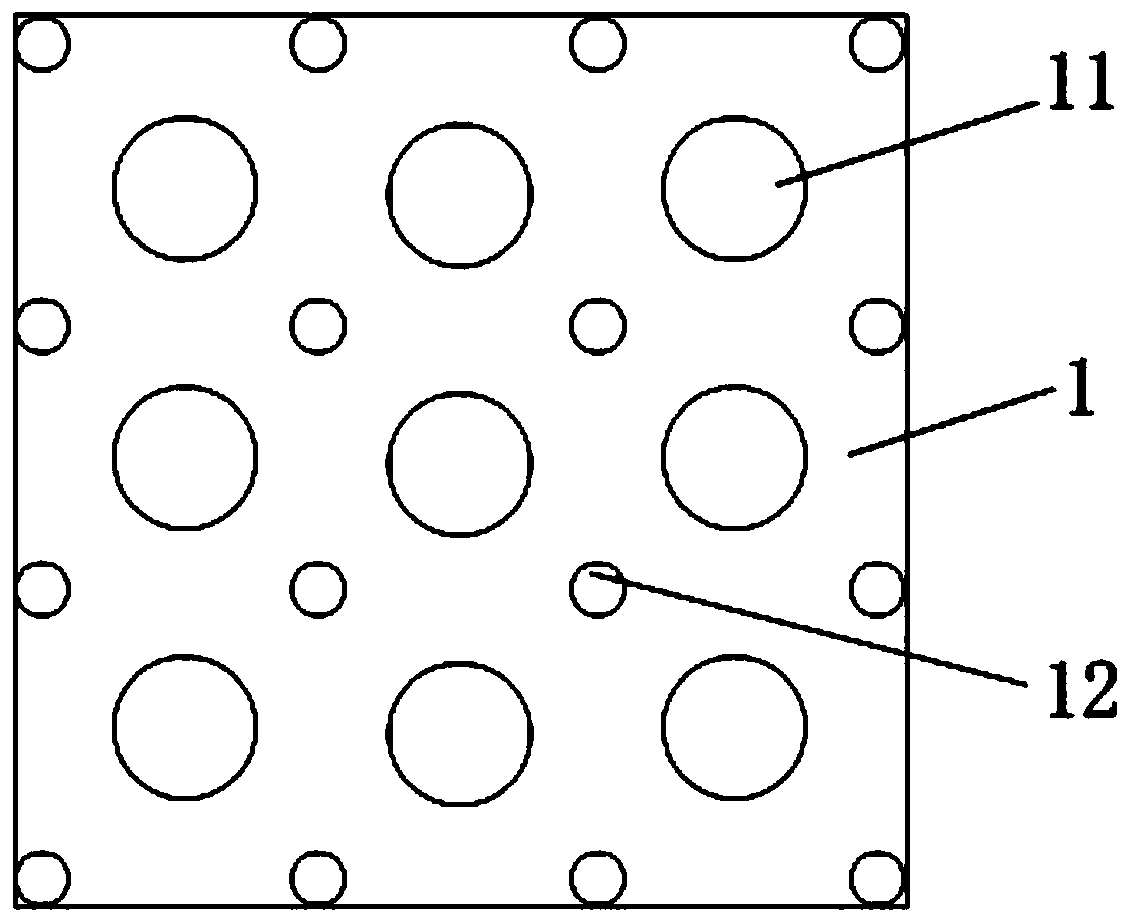

Water-permeable plastic runway

A technology of plastic runways and seepage holes, which is applied in the directions of roads, roads, pavement details, etc., can solve the problems of infiltration and drainage of accumulated water, and achieve the effect of good elasticity and avoidance of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1~4

[0024] Embodiment A1~4: Preparation of composite surface layer raw materials

Embodiment A1

[0026] Accurately weigh the following components by weight: 90 parts of PVC suspension resin, 50 parts of dioctyl terephthalate as a plasticizer, 70 parts of EPDM rubber particles, 30 parts of polyisocyanate, 20 parts of polyether polyol, 0.5 parts of low-molecular polyols, 0.3 parts of hydrogenated rosin as a tackifier, 0.5 parts of an antioxidant as an auxiliary agent and 0.3 parts of a carboxylate formed from metal potassium and oleic acid as a catalyst; after fully mixing the above raw materials, under negative pressure conditions Heated to 120°C for 6 hours and cooled for later use.

Embodiment A2

[0028] Accurately weigh the following components by weight: 100 parts of PVC suspension resin, 60 parts of dibutyl phthalate as plasticizer, 80 parts of EPDM rubber particles, 40 parts of polyisocyanate, 30 parts of polyether polyol, 2 parts of low-molecular polyols, 3 parts of rosin glycerides as tackifiers, 2 parts of anti-ultraviolet agents as auxiliary agents and 1 part of carboxylate formed by metallic calcium and naphthenic acid as catalysts; Heated to 130°C under high pressure for 7 hours and cooled for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com