Polypropylene resin for hot filling bottles

A polypropylene resin, hot filling technology, applied in the field of polypropylene resin, polypropylene resin for hot filling bottles, can solve the problems of poor rigidity and heat resistance, poor toughness and transparency, etc., achieve good crystallization ability, The effect of improving production efficiency and good crystallization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

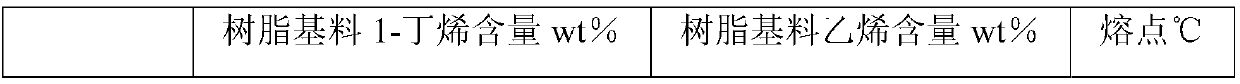

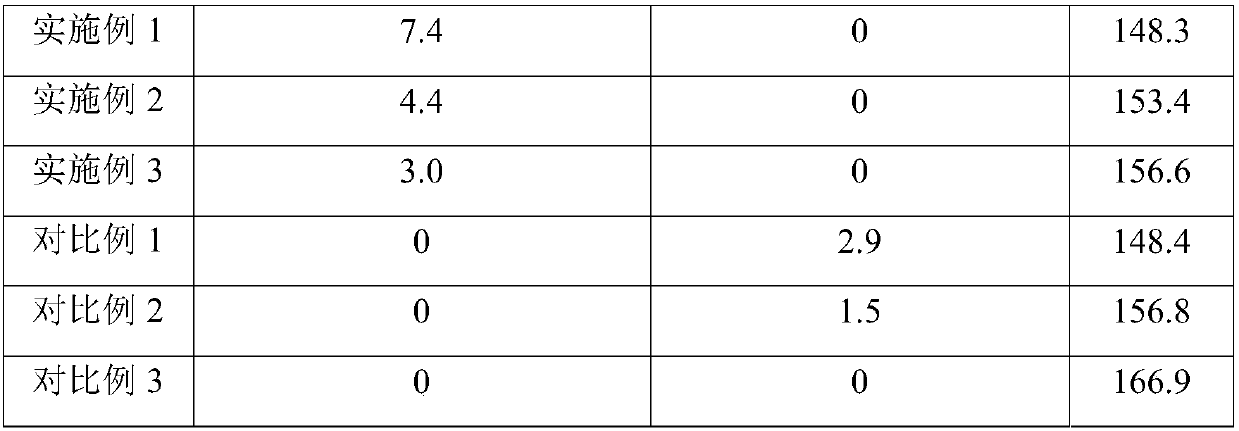

[0021] The characteristics of the propylene / 1-butene random copolymerized polypropylene resin used in the examples are shown in Table 1, and the melt flow rate is 8-12 g / 10 min.

[0022] The antioxidant in this example uses 1,3,5-trimethyl-2,4,6-tris(3,5-di-tert-butyl-4 hydroxybenzyl)benzene and tris(2,4-di-tert-butyl phenyl)phosphite mixture, the ratio of the two is 1:1; the nucleating agent is 2,2'-methylene-bis(4,6-di-tert-butylphenyl)sodium phosphate; And the agent is calcium stearate. The ratio of polypropylene resin base material to antioxidant, nucleating agent and acid neutralizer is 100:0.15:0.06:0.05.

[0023] In the examples, the propylene / 1-butene random copolymerized polypropylene resin base material is mixed with additives such as antioxidants, nucleating agents, and acid neutralizers, and granulated by melt extrusion to prepare propylene / 1- Butene random copolymerization polypropylene resin.

Embodiment 4

[0026] The melt flow rate of the propylene / 1-butene random copolymerized polypropylene resin used is 3.0g / 10min, and the antioxidant is 1,3,5-trimethyl-2,4,6-tri(3,5-di A mixture of tert-butyl-4-hydroxybenzyl)benzene and tris(2,4-di-tert-butylphenyl)phosphite, the ratio of the two is 1:0.3; the nucleating agent is 2,2'-methylene Base-sodium bis(4,6-di-tert-butylphenyl)phosphate; acid neutralizer is calcium stearate. The ratio of polypropylene resin base material to antioxidant, nucleating agent and acid neutralizer is 100:0.02:0.01:0.01. The steps for preparing the propylene / 1-butene random copolymerized polypropylene resin are the same as in Example 1.

Embodiment 5

[0028] The melt flow rate of the propylene / 1-butene random copolymerized polypropylene resin used is 25.0g / 10min, and the antioxidant is 1,1,3-tris(2-methyl-4-hydroxy-5-tert-butylbenzene base) butane and tris(2,4-di-tert-butylphenyl)phosphite, the ratio of the two is 1:8; the nucleating agent is 2,2′-methylene-bis(4, 6-di-tert-butylphenyl) sodium phosphate; acid neutralizer is hydrogenated talc. The ratio of polypropylene resin base material to antioxidant, nucleating agent and acid neutralizer is 100:0.25:0.10:0.08. The steps for preparing the propylene / 1-butene random copolymerized polypropylene resin are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com