Method for promoting biofilm culturing effect by modifying surface of polyurethane

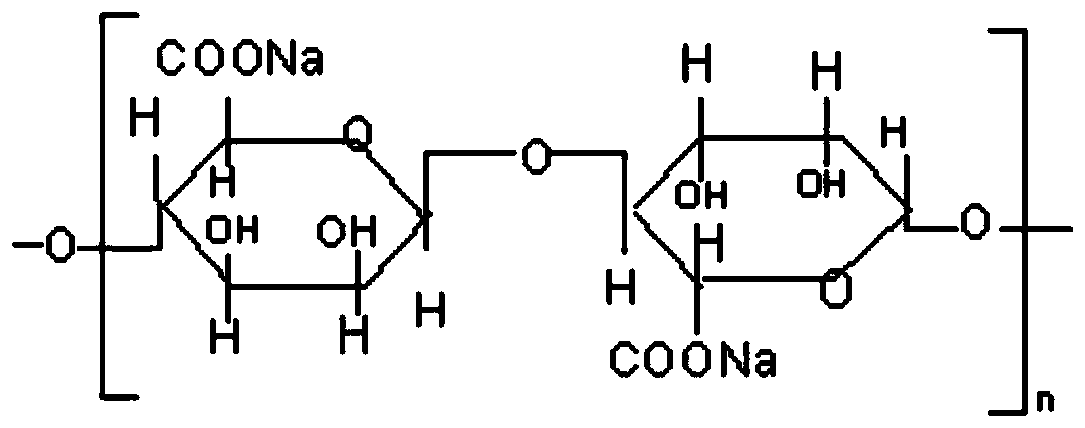

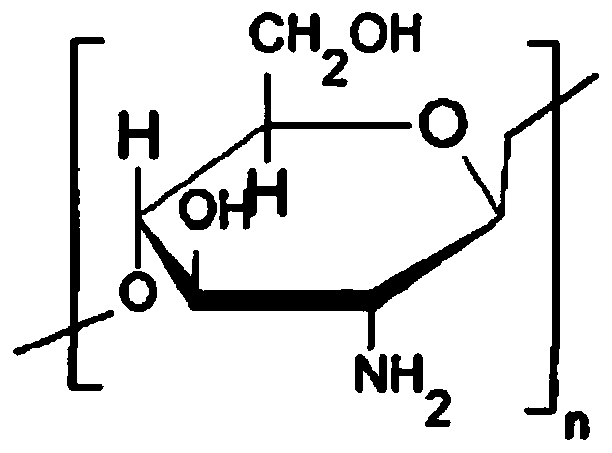

A surface modification, polyurethane technology, applied in the field of water treatment, can solve the problems of lack of surface charge, unfavorable heterogeneous charge deposition, accelerated biofilm maturation, etc., to achieve the effect of promoting film hanging effect, abundant raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

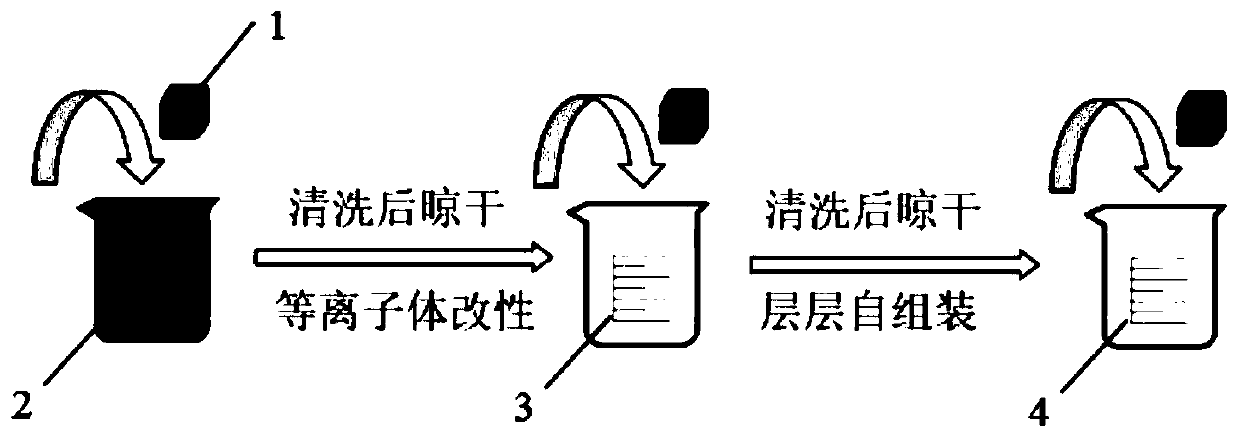

[0049] The method for promoting the film-hanging effect to polyurethane surface modification of the present invention, comprises the steps:

[0050] (1) The preparation of adding 0.08mol / L ferrous sulfate heptahydrate solution to 0.008mol / L acidic potassium permanganate solution (volume ratio of concentrated sulfuric acid to deionized water is 1:499) at a volume ratio of 1:0.8 Obtain iron manganese salt solution.

[0051] (2) Take an appropriate amount of polyurethane sponge and immerse it in the iron-manganese salt solution, heat it in a water bath at 45°C for 1.5h, take it out, and wash it fully with 0.01mol / L PBS phosphate buffer solution until the washed solution is neutral. Naturally dry for later use;

[0052] (3) Place the processed material in step 2) in a low-temperature plasma processor, and adjust the gas volume to 18cm 3 / min, apply a power of 150W to generate plasma, and process 3min under this condition;

[0053] (4) Add the material treated in step 3) into a ...

Embodiment 2

[0057] The method for promoting the film-hanging effect to polyurethane surface modification of the present invention, comprises the steps:

[0058] (1) Add 0.12mol / L ferrous sulfate heptahydrate solution to 0.012mol / L acidic potassium permanganate solution (volume ratio of concentrated sulfuric acid to deionized water is 1:500) at a volume ratio of 1:1.2. Obtain iron manganese salt solution.

[0059] (2) Take an appropriate amount of polyurethane sponge and immerse it in the iron-manganese salt solution, heat it in a water bath at 55°C for 2.5 hours, take it out, and wash it fully with 0.05mol / L PBS phosphate buffer solution until the washed solution is neutral. Naturally dry for later use;

[0060] (3) Place the material processed in step (2) in a low-temperature plasma processor, and adjust the gas volume to 22cm 3 / min, apply a power of 200W to generate plasma, and process 7min under this condition;

[0061] (4) Add the material treated in step (3) into the sodium algin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com