Small independent suction machine

A self-contained, suction machine technology, used in conveyors, conveying bulk materials, transportation and packaging, etc., can solve problems such as complex structure, and achieve the effect of small size, high safety and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

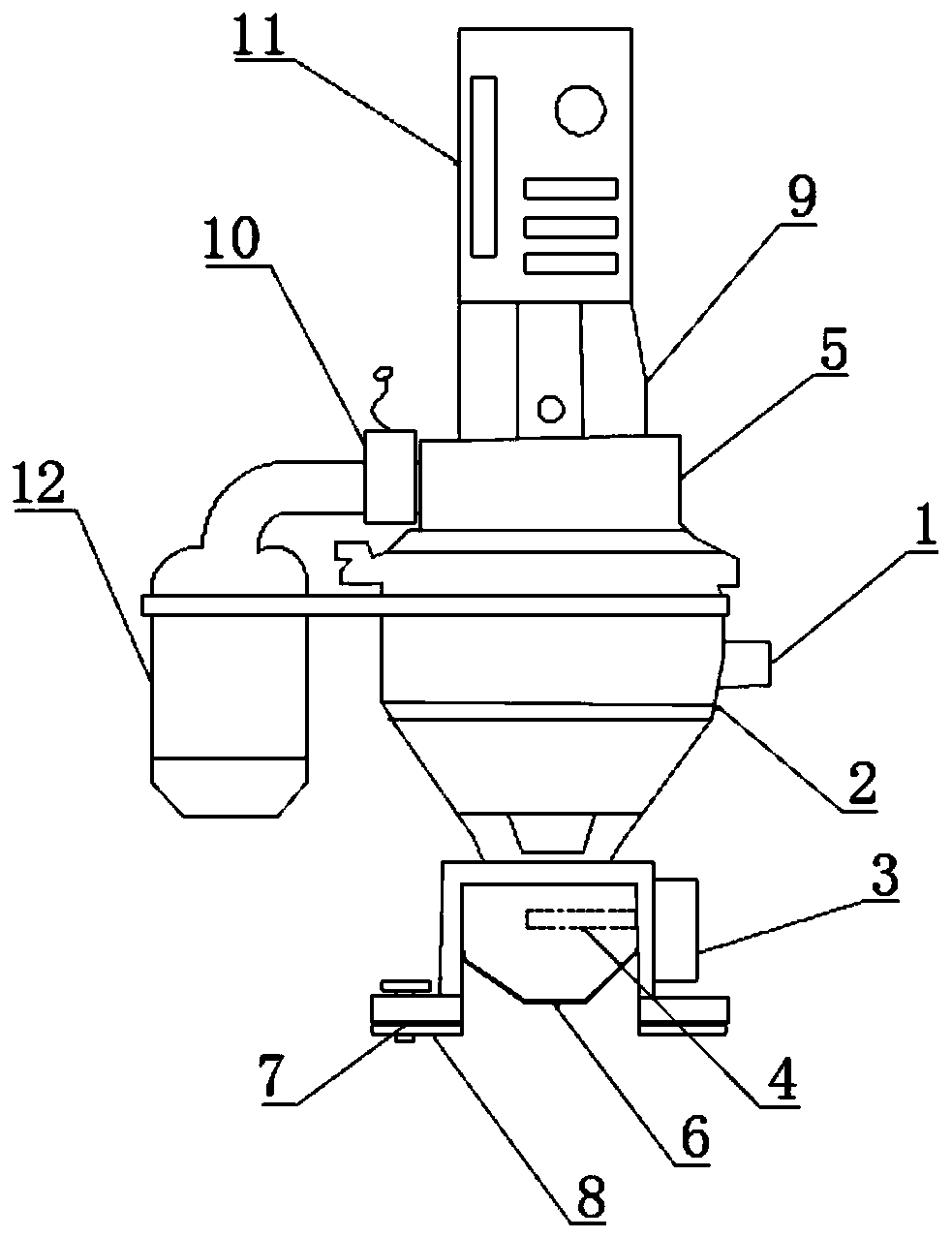

[0020] Such as figure 1 As shown, a small independent suction machine includes a hopper 2, a connecting cylinder 6, a fan 9, and a microcomputer control unit 11,

[0021] The side of the hopper 2 is provided with a feed port 1, and the feed port 1 can be connected with an extension pipe to absorb various raw materials.

[0022] The hopper 2 is conical, and the bottom is provided with a connecting cylinder 6 and a mounting seat 7. The connecting cylinder 6 has various specifications and can be replaced and connected to the raw material inlet of the equipment; the mounting seat 7 is connected by a bolt, nut assembly or magnetic Components are firmly connected to the device,

[0023] The side of the connecting cylinder 6 is provided with a contact switch 3, the contact switch 3 is connected with a contact rod 4, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com