Method for manufacturing rubber shoe with foaming lining layer

A technology of rubber shoes and manufacturing method, which is applied in the direction of footwear, shoe uppers, footwear, etc., and can solve the problems of not filling the foam layer, increasing the pressure of inventory management, and complicated processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] In order to make those skilled in the art have a further understanding of the present invention, a preferred embodiment is enumerated in conjunction with the drawings, and the detailed description is as follows:

[0076] See first Figure 1 to Figure 14 Shown, the method for making rubber shoes of the tool foam inner layer of the present embodiment has included the following steps:

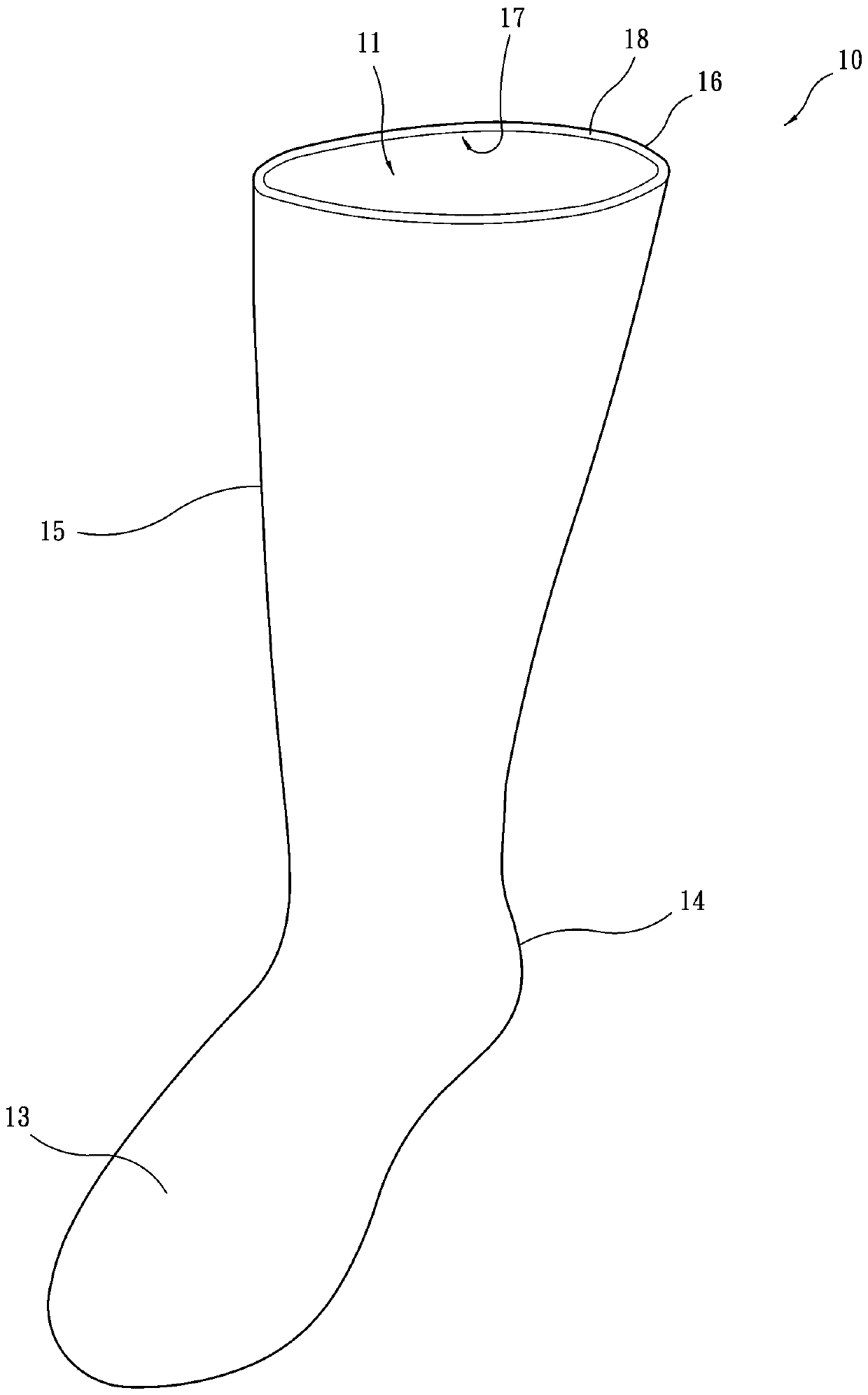

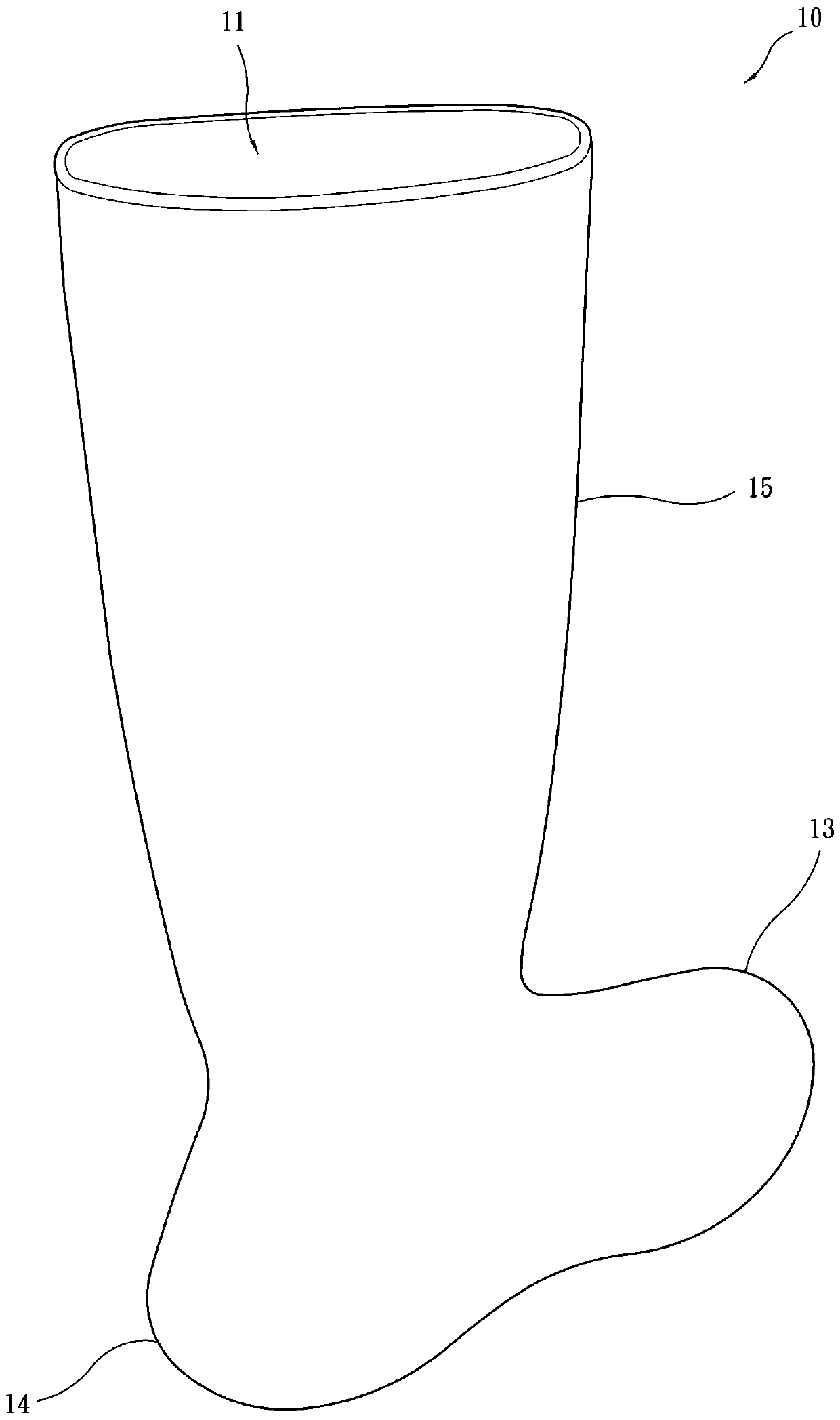

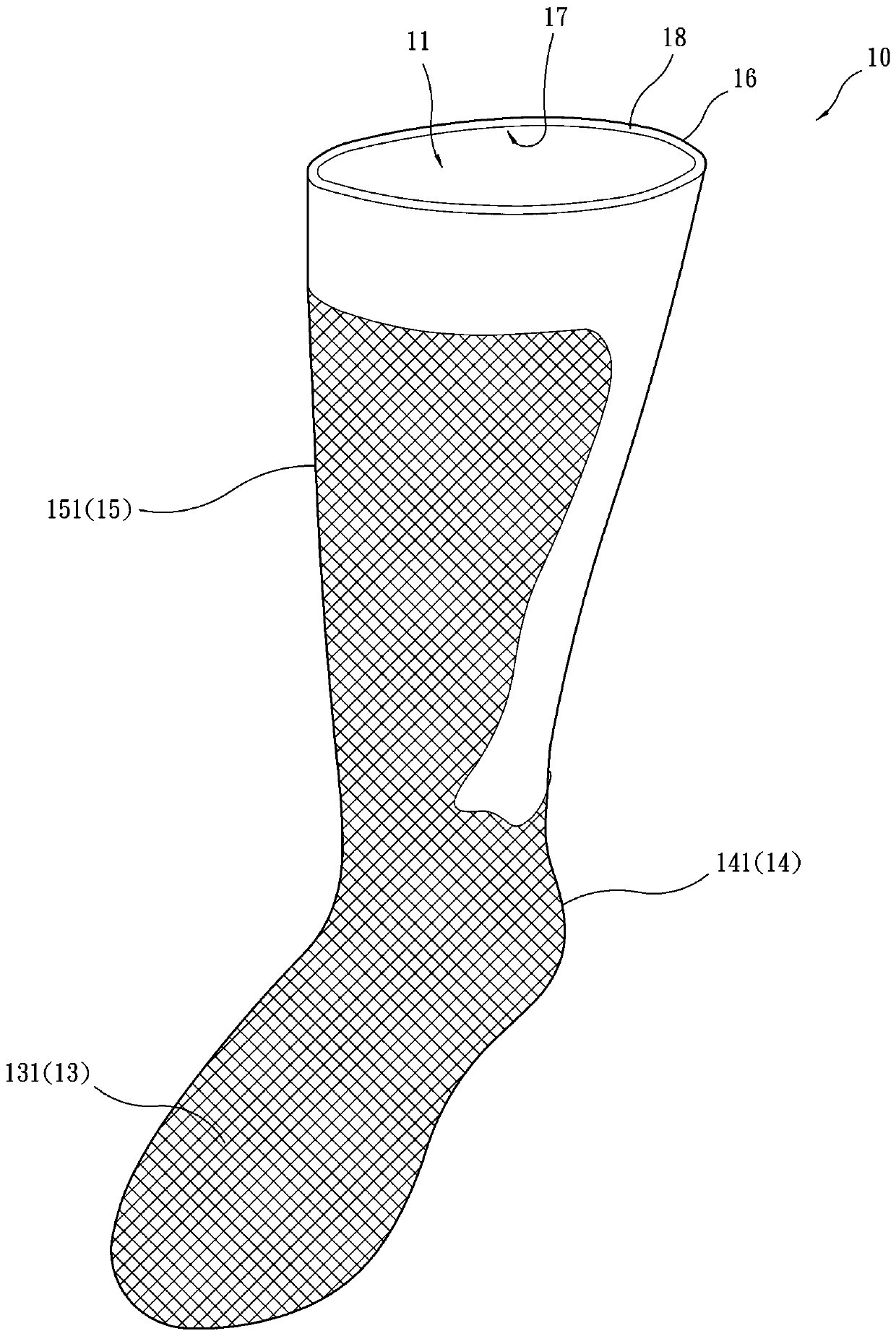

[0077] The first is the coating of the shoe-shaped inner cover: a soft foam material with a certain thickness is made into a shoe-shaped inner cover 10, and is applied to the sole 12, vamp portion 13, heel 14, All or part of the shoe barrel 15 is pre-coated with a layer of hardened rubber coating to form a sole coating 121 , a vamp coating 131 , a heel coating 141 and a shoe barrel coating 151 . Wherein, the shoe-shaped inner cover 10 can be cut into a desired shape from a planar foam material, and then sewn into a shoe-shaped inner cover. Layer 141 and shoe shaft coating 151 can be appli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com