Full-automatic high-speed laser pole piece cutting equipment

A fully automatic, cutting technology, used in laser welding equipment, welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

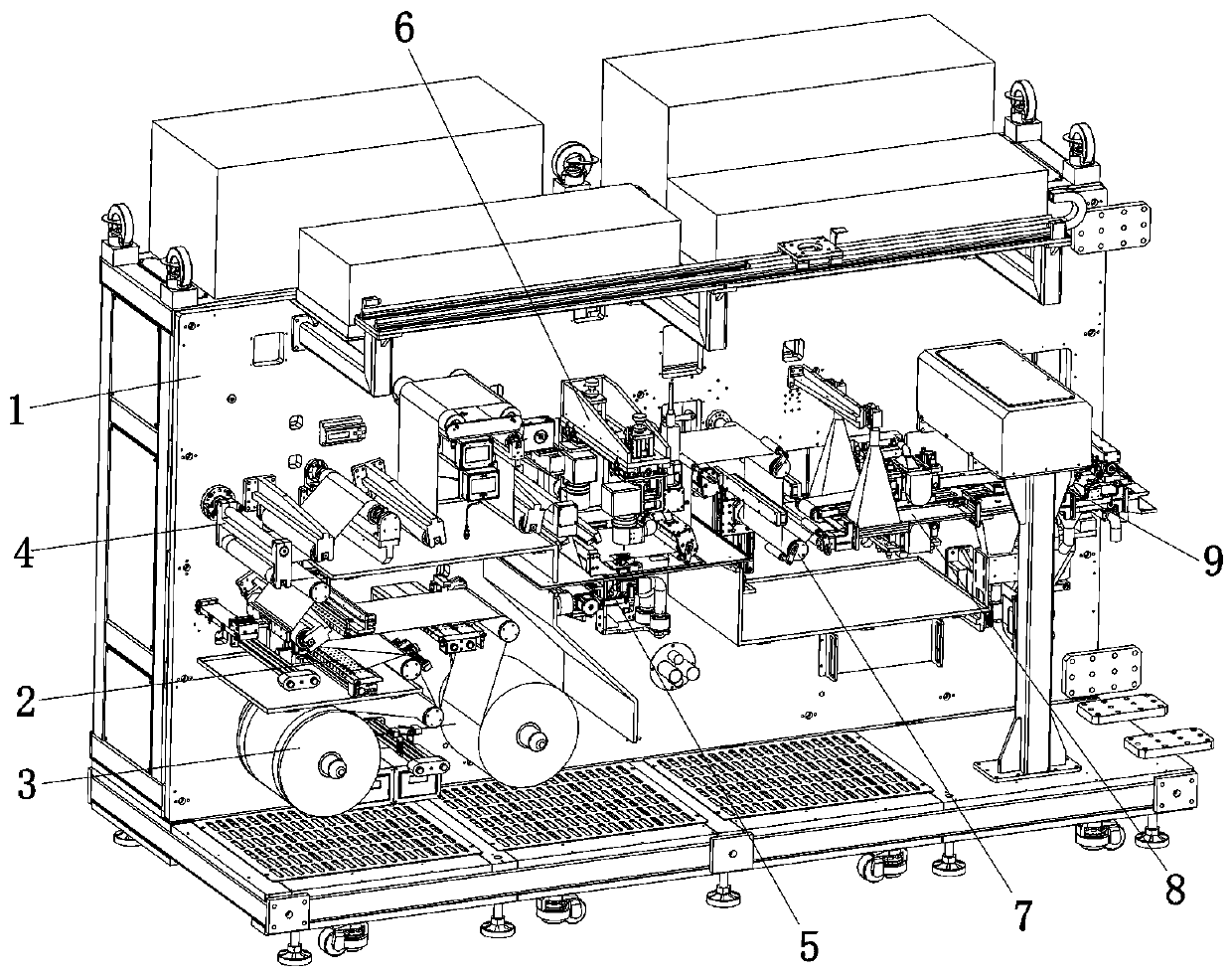

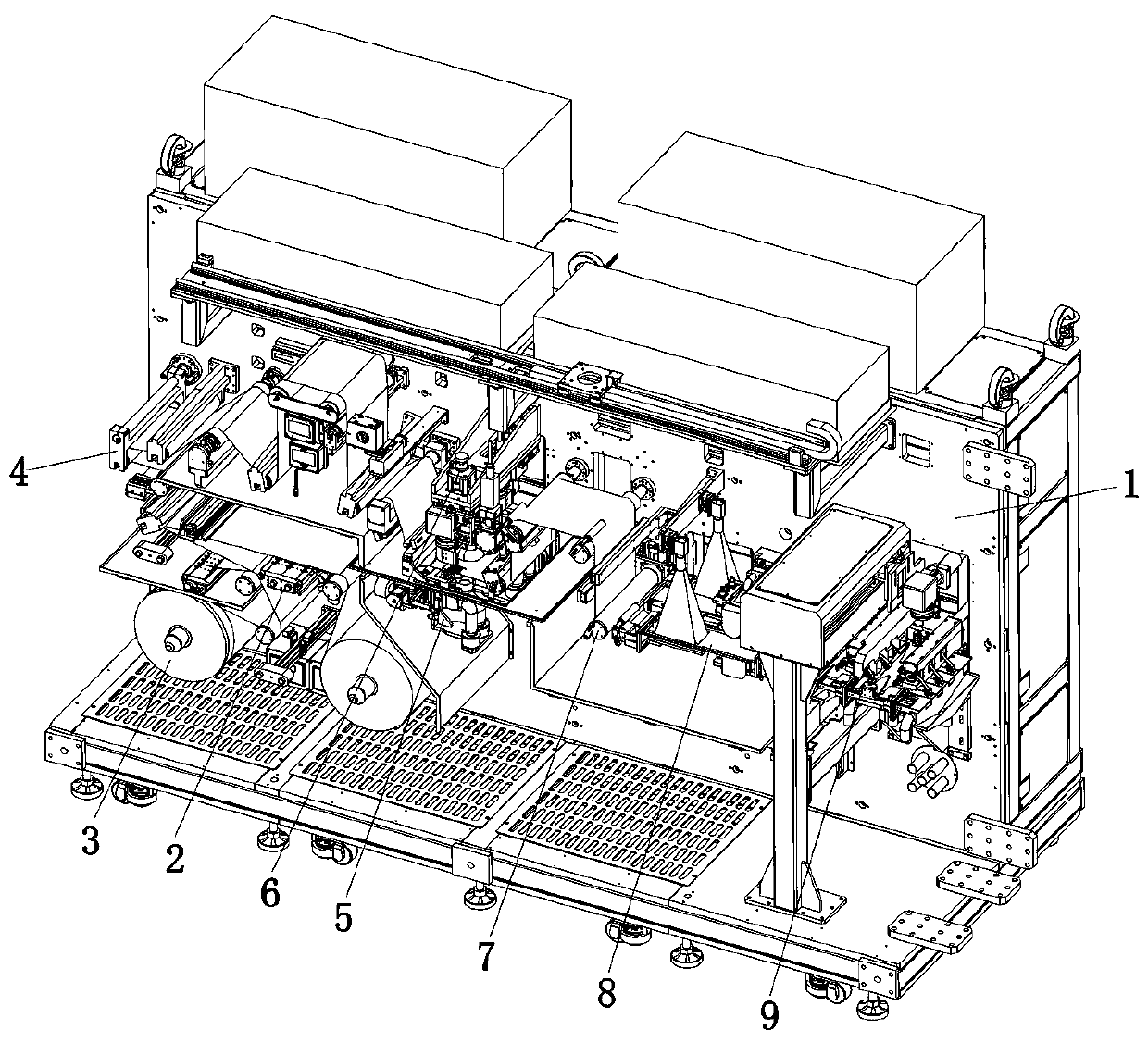

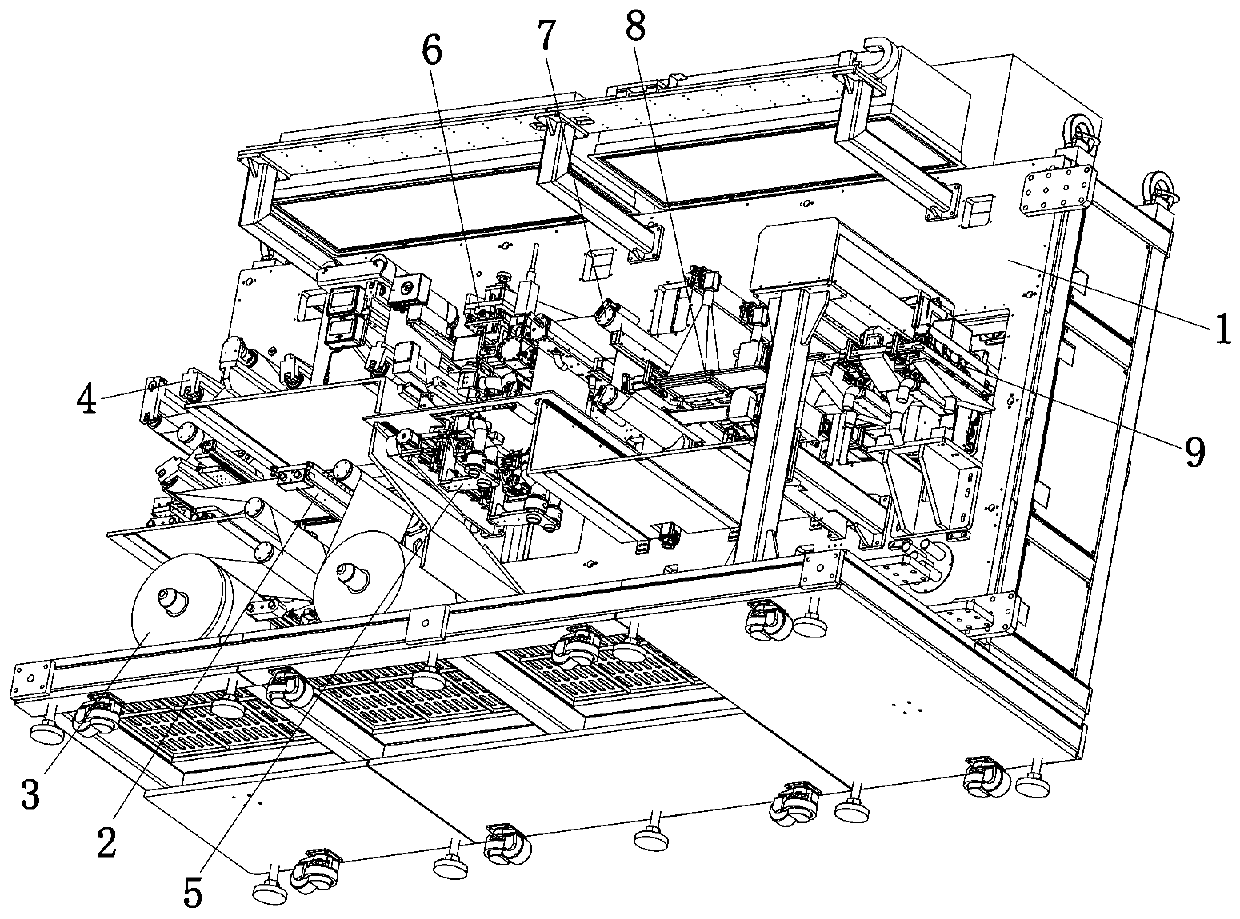

[0087] The present invention will be further described below in conjunction with the accompanying drawings:

[0088] Such as Figure 1 to Figure 42 As shown, the technical solution adopted by the present invention is as follows: a fully automatic high-speed laser pole piece cutting equipment, including pole piece material roll 3, material receiving mechanism 2, connecting rod tensioning mechanism 4, lug cutting mechanism, conveying traction The mechanism 8 and the pole piece cutting mechanism 9, wherein the above-mentioned pole piece material roll 3 includes two, the two pole piece material rolls 3 are arranged on the side wall of the frame 1; the above-mentioned material receiving mechanism 2 is arranged on the pole piece material roll 3 On the side, the strip-shaped pole piece derived from the pole piece material roll 3 extends outward through the material receiving mechanism 2; the above-mentioned connecting rod tensioning mechanism 4 is arranged on the side of the material re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com