Adhesive film and optical member comprising same

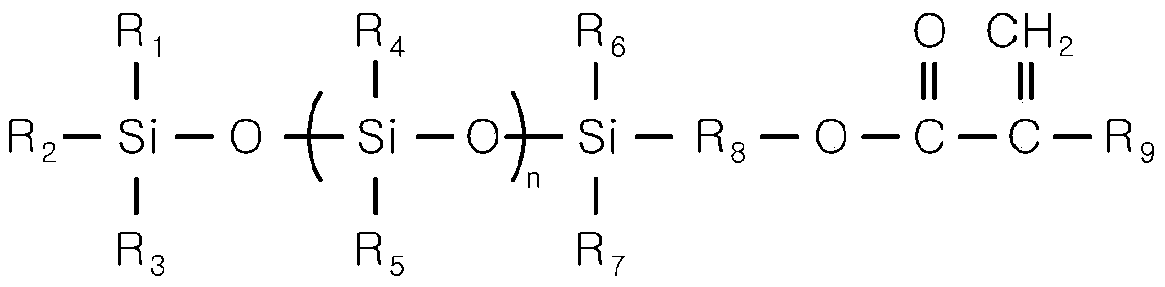

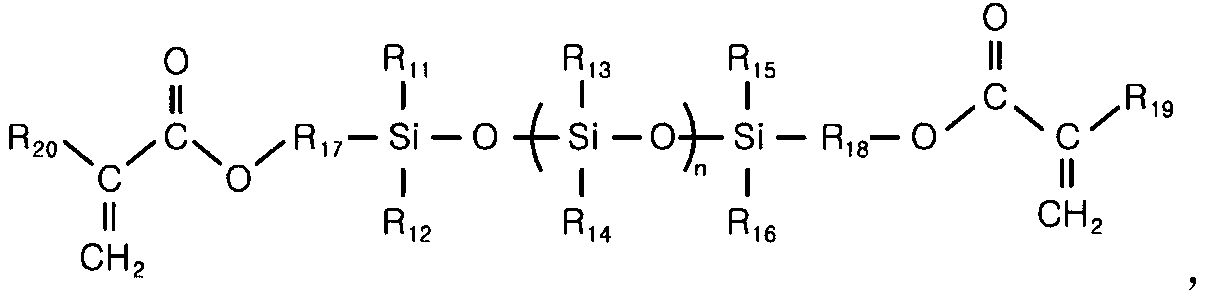

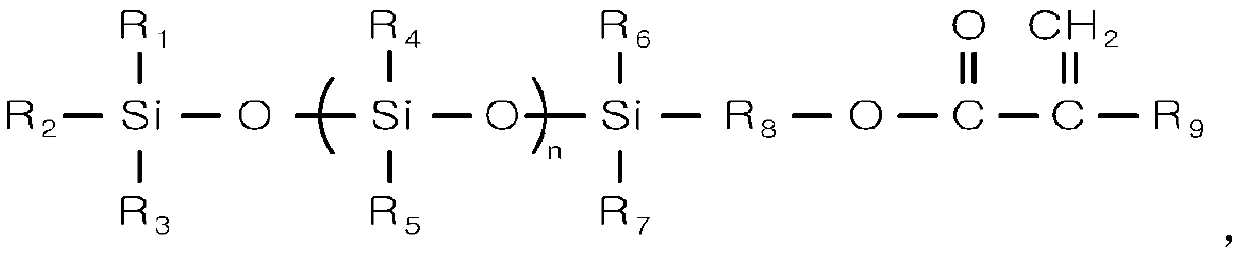

A methacrylic ester technology, applied in the direction of optical components, optics, film/sheet adhesive, etc., can solve the problems of adverse effects on the properties of the protective film, and achieve excellent residual properties, good compatibility, and high curing speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0211] Next, the present invention will be explained in detail with reference to some examples. It should be understood, however, that these examples are provided for illustration only and should not be construed as limiting the invention in any way.

example 1

[0213] 100 parts by weight of the monomer mixture listed in Table 1 and 0.005 parts by weight of Yanjiagu 651 as a starter were thoroughly mixed in the reactor. After displacing dissolved oxygen in the reactor with nitrogen, the monomer mixture was partially polymerized by irradiating ultraviolet light for several minutes using a low-pressure mercury lamp, thereby preparing a viscous liquid with a viscosity of 2,000 cps at 25°C. The viscous liquid may comprise a copolymer of an acrylic monomer and a silicon-containing monomer, a mixture of the acrylic monomer and the silicon-containing monomer unpolymerized.

[0214] Added 0.5 parts by weight of initiator Yanjiagu 651 to the viscous liquid and mixed it, thereby preparing the adhesive composition. After removing air bubbles from the adhesive composition, the adhesive composition was coated on one surface of a PET (polyethylene terephthalate) base film (thickness: 75 μm), and the PET (polyethylene terephthalate) Ethylene glycol...

example 2 to example 9

[0216] A PET film / adhesive film / PET film adhesive sheet was prepared in the same manner as in Example 1, except that the components of each adhesive composition were changed to those listed in Table 1 (unit parts by weight).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com