Ternary positive electrode composite material and preparation method and application thereof

A technology of composite materials and positive electrode materials, which is applied in the field of ternary positive electrode composite materials and its preparation, can solve the problems of surface structure damage of positive electrode materials, influence of electrochemical performance of materials, environmental protection pressure of washing water, etc., and achieves uniform distribution and coating effect. Unaffected, low microwave temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

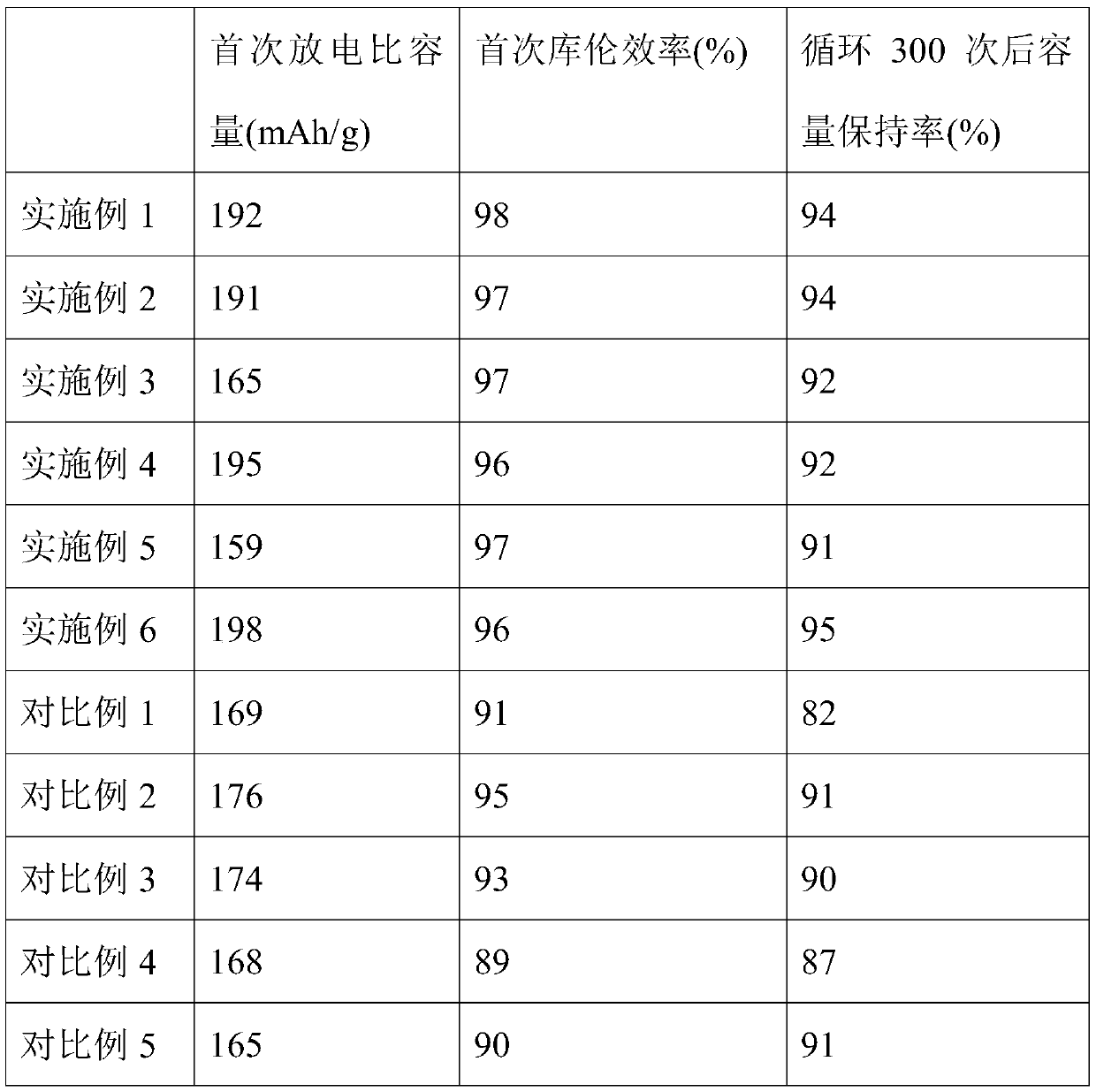

Examples

Embodiment 1

[0073] Among the positive electrode materials described in this embodiment, the ternary positive electrode material is nickel-cobalt lithium manganese oxide, and the molar ratio of nickel, cobalt and manganese is Ni:Co:Mn=7:1: 1. The mass percentage of the first coating is 10%, the second coating is the carbonized product of polyvinyl alcohol, and the usage amount of polyvinyl alcohol is 0.1%,

[0074] In the first cladding, conductive polymer / graphene / carbon nanotube composite, hydrogen-containing lithium titanium oxide compound and FeF 3 (H 2 O) 0.33 The mass ratio of the conductive polymer, graphene and carbon nanotubes in the conductive polymer / graphene / carbon nanotube composite is 1:1.5:1.5;

[0075] The preparation method of described cathode material comprises the following steps:

[0076] (1) polyvinyl alcohol PVA is dissolved in water, is mixed with solution A;

[0077] (2) Add the first coating to the solution A obtained in step (1), stir well to obtain solution ...

Embodiment 2

[0084] Among the positive electrode materials described in this embodiment, the ternary positive electrode material is nickel-cobalt lithium manganese oxide, and the molar ratio of nickel, cobalt and manganese is Ni:Co:Mn=6:2: 2. The mass percentage of the first coating is 0.5%, the second coating is the carbonized product of polyvinyl alcohol, and the usage amount of polyvinyl alcohol is 2%,

[0085] In the first cladding, conductive polymer / graphene / carbon nanotube composite, hydrogen-containing lithium titanium oxide compound and FeF 3 (H 2 O) 0.33 The mass ratio is 7:2.5:0.5; the mass ratio of conductive polymer, graphene and carbon nanotube in the conductive polymer / graphene / carbon nanotube composite is 0.2:3:0.8;

[0086] (1) polyvinyl alcohol PVA is dissolved in ethanol, is mixed with solution A;

[0087] (2) Add the first coating to the solution A obtained in step (1), stir well to obtain solution B;

[0088] (3) adding the ternary positive electrode material into ...

Embodiment 3

[0094] Among the positive electrode materials described in this embodiment, the ternary positive electrode material is nickel-cobalt lithium manganese oxide, and the molar ratio of nickel, cobalt and manganese is Ni:Co:Mn=5:3: 2. The mass percentage of the first coating is 15%, the second coating is the carbonized product of polyvinyl alcohol, and the usage amount of polyvinyl alcohol is 0.5%.

[0095] In the first cladding, conductive polymer / graphene / carbon nanotube composite, hydrogen-containing lithium titanium oxide compound and FeF 3 (H 2 O) 0.33 The mass ratio is 9.4:0.5:0.1; the mass ratio of conductive polymer, graphene and carbon nanotube in the conductive polymer / graphene / carbon nanotube composite is 2:0.1:2.6;

[0096] The preparation method of described cathode material comprises the following steps:

[0097] (1) polyvinyl alcohol PVA is dissolved in ethanol, is mixed with solution A;

[0098] (2) Add the first coating to the solution A obtained in step (1), s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com