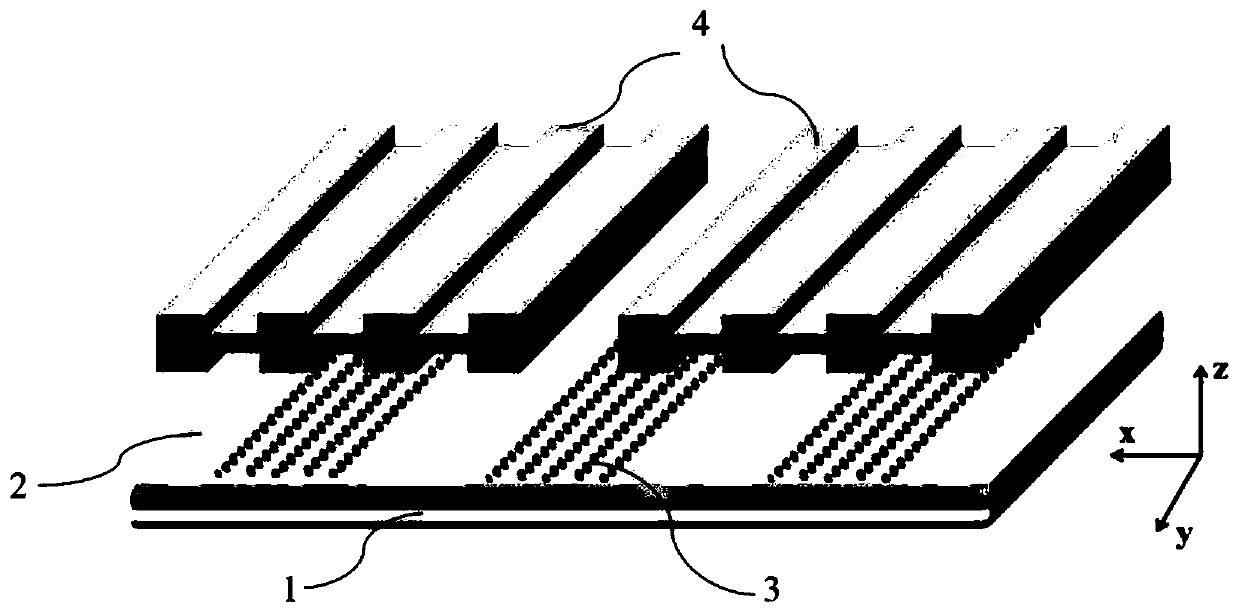

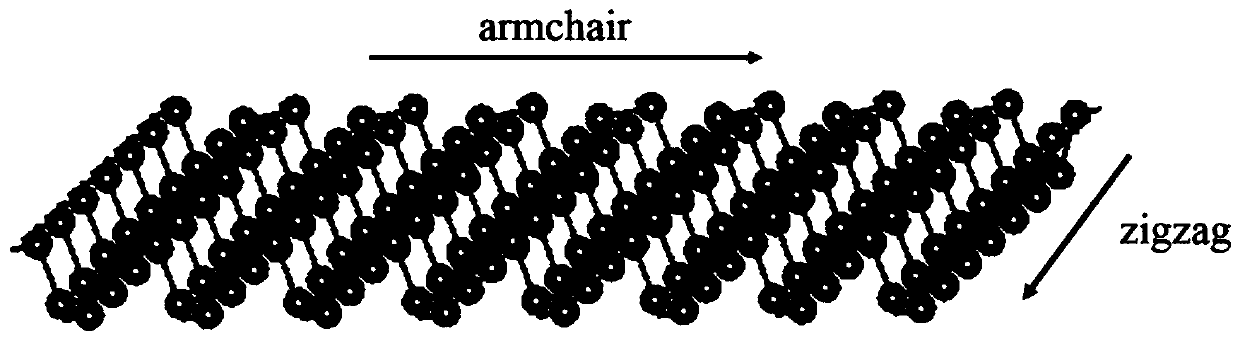

Super-absorption structure based on black phosphorus nano-strip arrays and metal grating slit

A metal grating and nano-stripe technology, applied in the field of ions, can solve the problems of few researchers, and achieve the effect of high flexibility, wide application area and enhanced absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Example: Fabrication of a superabsorbent structure based on black phosphorus nanobar arrays and metal grating slits.

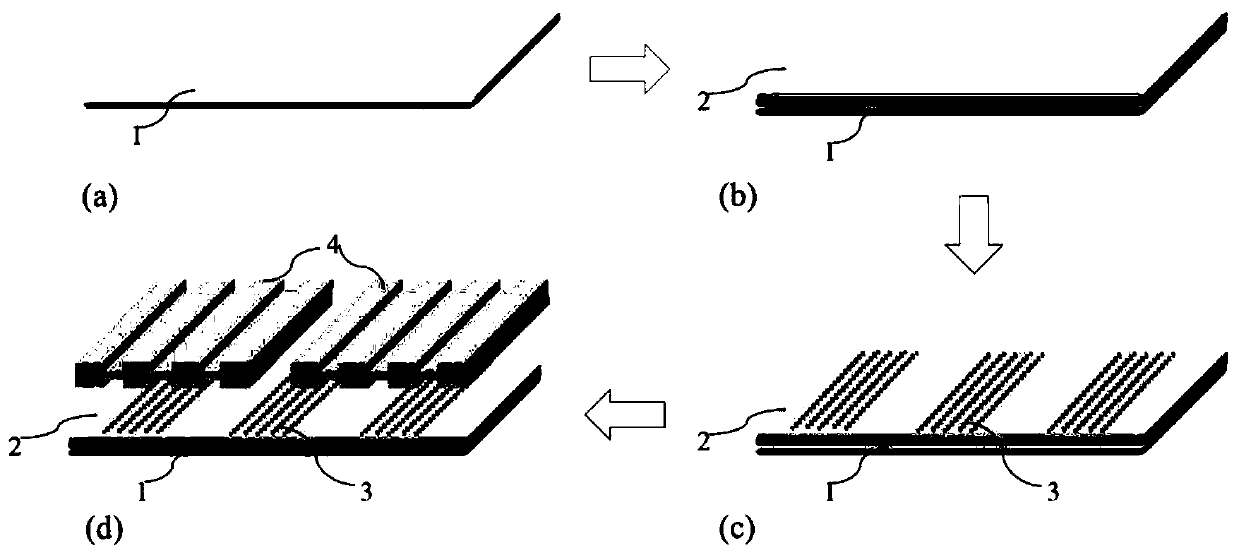

[0030] refer to image 3 , the implementation steps of this example are as follows:

[0031] Step 1: Deposit Al metal layer

[0032] Using plasma-enhanced chemical vapor deposition process, with solid Al (99.99% purity) as the evaporation source, the dielectric substrate was heated to 380°C for vacuum degassing for 3 hours, and the air flow was maintained for 15 to 90 minutes during ventilation, and the pressure was between 0.4 and 2.4 milliliters. Between bars, the plasma is formed by 13.6MHz radio frequency power, and finally the dielectric substrate is etched away to form a 300nm thick Al metal reflective layer 1, such as image 3 (a).

[0033] Step 2: Growing SiO 2 Dielectric layer

[0034] Then use the thermal oxidation process, the method of combining dry and wet oxygen, and grow SiO at a temperature of 900 degrees. 2 Oxide dielectric layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com