Surface corrosion treatment method of boron carbide product, metallographic specimen and preparation method thereof

A technology for corrosion treatment and metallographic samples, which is applied in the field of boron carbide product processing, can solve the problems of difficult operation control of corrosion temperature and corrosion time, unclear, incomplete corrosion interface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

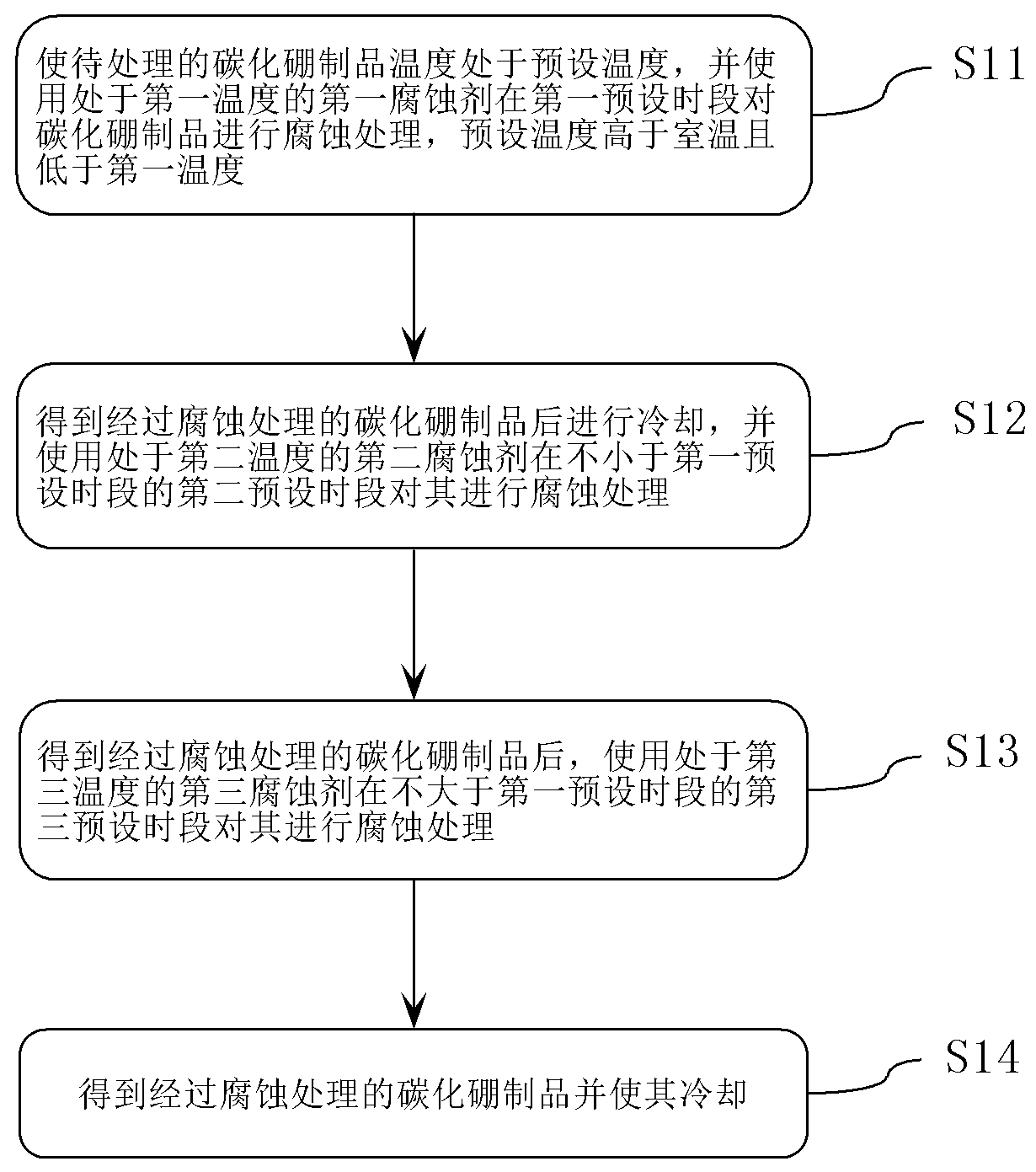

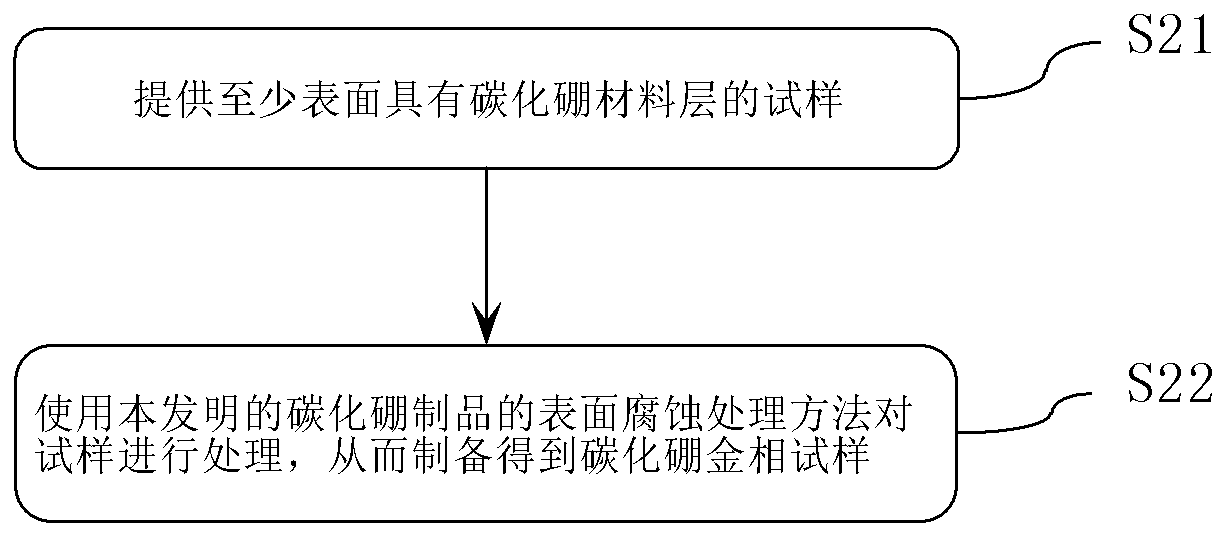

Method used

Image

Examples

Embodiment approach

[0041] For another example, in the foregoing embodiments, the first etchant and the third etchant use alkaline solutions, while the second etchant uses acid solutions, so that acid-base cross-corrosion treatment can be performed on the surface of the boron carbide product. However, in some embodiments, it is also conceivable to use an acidic solution for the first etchant and the third etchant, and an alkaline solution for the second etchant, so that the effect of acid-base cross-corrosion treatment can also be formed. Of course, in other embodiments, the present invention also allows the above corrosive agents to be used in various possible other corrosive solutions according to specific application conditions.

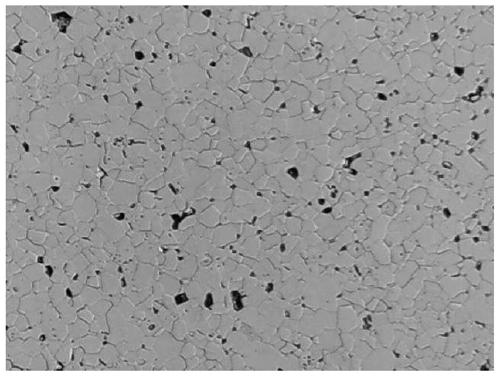

[0042] The following will further combine figure 2 The metallographic picture example shown is used to illustrate the surface corrosion treatment method of boron carbide products according to the present invention, so that the technical solution of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com