Hydro-cracking method for reducing bromine index of heavy naphtha and increasing smoke point of aviation kerosene

A technology for hydrocracking and heavy naphtha, which is applied in the petroleum industry, hydrotreating process, processing hydrocarbon oil, etc. Problems such as unqualified soot point, to achieve the effect of inhibiting activity and inhibiting secondary cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

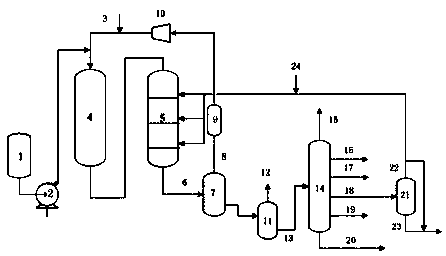

Image

Examples

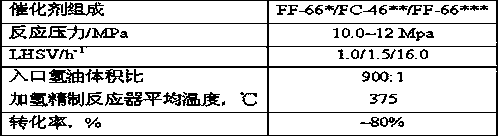

Embodiment 1

[0032] Taking Daqing VGO as the raw material oil, FF-36 as the hydrorefining agent, and FC-46 as the hydrocracking agent, the actual operating process conditions are shown in Table 3, and the reaction pressure is set at 12 MPa. After the low-fraction oil enters the fractionation tower, the jet fuel fraction enters the separator to be cut into light and heavy jet fuel, and the cutting point is 220°C. The mass ratio of light aviation kerosene to the jet kerosene product out of the unit is 1.0, and pyrrole is injected at the nitrogen injection point, and the mass ratio of injection amount to light aviation kerosene is 0.01. The mixture of aromatic nitrogen compound and light aviation coal enters each hydrocracking reactor area uniformly from the first bed layer.

Embodiment 2

[0034] Taking Daqing VGO as the raw material oil, FF-36 as the hydrorefining agent, and FC-46 as the hydrocracking agent, the actual operating process conditions are shown in Table 3, and the reaction pressure is set at 12 MPa. After the low-fraction oil enters the fractionation tower, the jet fuel fraction enters the separator to be cut into light and heavy jet fuel, and the cutting point is 220°C. The mass ratio of light aviation kerosene to the jet kerosene product out of the unit is 1.0, and pyrrole is injected at the nitrogen injection point, and the mass ratio of injection amount to light aviation kerosene is 0.01. The mixture of aromatic nitrogen compound and light aviation coal enters each hydrocracking reactor area from the first bed layer, and the circulation ratio along the flow direction is 1.5.

Embodiment 3

[0036] Taking Daqing VGO as the raw material oil, FF-36 as the hydrorefining agent, and FC-46 as the hydrocracking agent, the actual operating process conditions are shown in Table 3, and the reaction pressure is set at 12 MPa. After the low-fraction oil enters the fractionation tower, the jet fuel fraction enters the separator to be cut into light and heavy jet fuel, and the cutting point is 220°C. The mass ratio of light aviation kerosene to the jet kerosene product out of the unit is 1.0, and pyrrole is injected at the nitrogen injection point, and the mass ratio of injection amount to light aviation kerosene is 0.01. The mixture of aromatic nitrogen compound and light aviation coal enters each hydrocracking reactor area from the second bed layer, and the circulation ratio along the flow direction is 1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com