A kind of joint waterproof sealing paste for polymer coil and preparation method thereof

A node waterproof and polymer technology, applied in coatings, conjugated diene coatings, etc., can solve problems such as difficult reaction compatibility, water channeling, lack of active groups, etc., to enhance sealing and waterproof capabilities and avoid fillers Good effect of agglomeration and surface permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

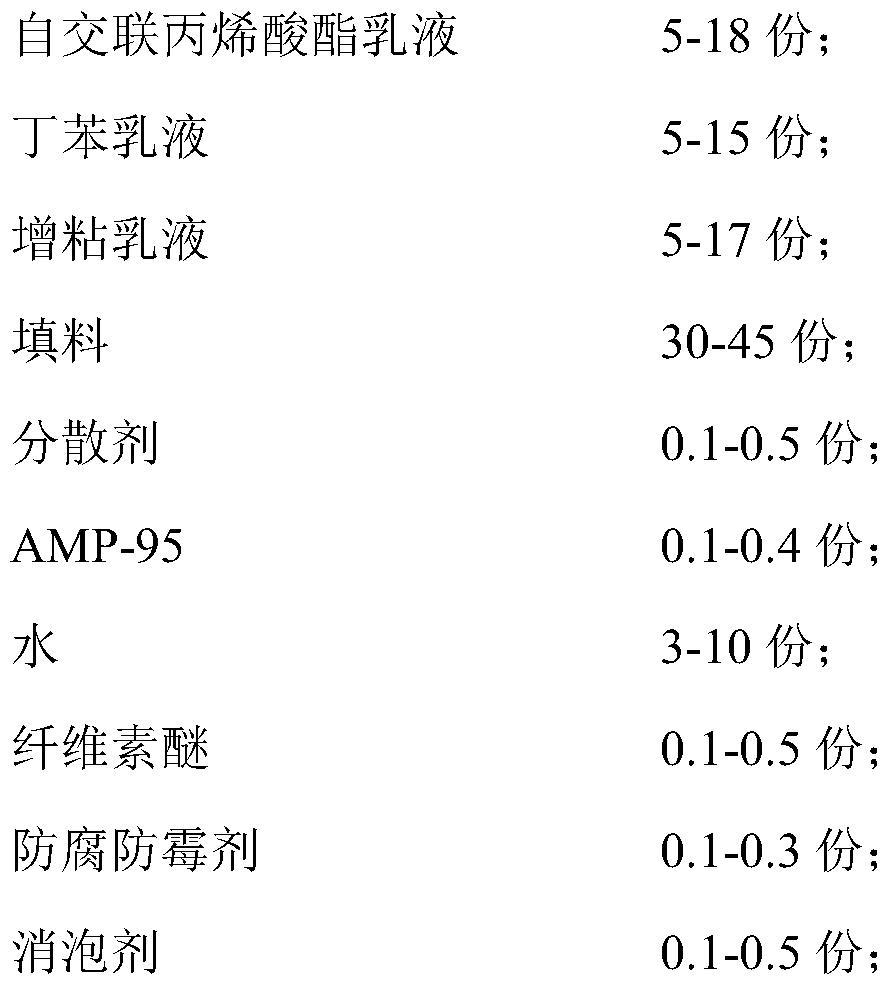

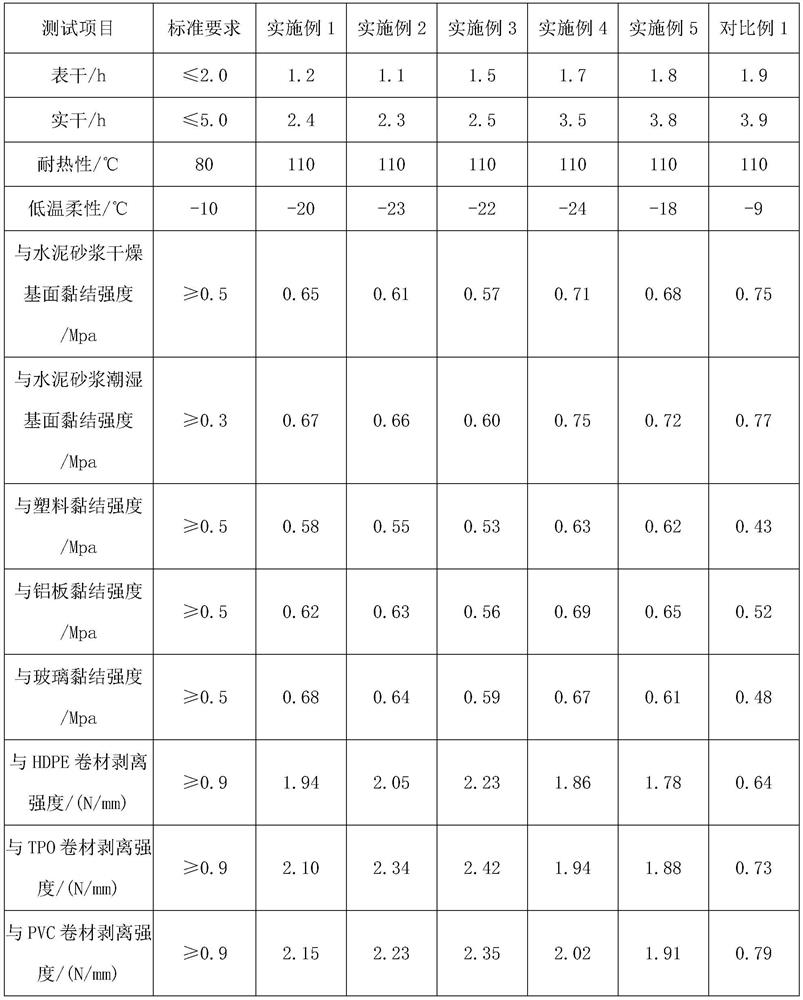

Embodiment 1

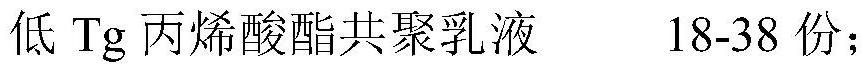

[0027] A node waterproof sealant paste for polymer coils, consisting of the following components calculated in parts by weight:

[0028] Low Tg acrylate copolymer emulsion (PLEXTOL A 315) 25 parts;

[0029] 9 parts of self-crosslinking acrylate emulsion (Neocryl A-1127);

[0030] 10 parts of styrene-butadiene emulsion (Lipaton SB 29Y57);

[0031] Viscosifying emulsion (Snowtack SE 780G) 12 parts;

[0032] 39 parts of filler (1000 mesh superfine barium sulfate);

[0033] 0.4 parts of dispersant;

[0034] AMP-95 0.2 parts;

[0035] 3.6 parts of water;

[0036] 0.4 part of cellulose ether;

[0037] 0.1 part of antiseptic and antifungal agent;

[0038] 0.3 part of defoamer.

[0039] The preparation method of the node waterproof sealant for the polymer coil is as follows:

[0040] S1. Add low Tg acrylic acid copolymer emulsion, self-crosslinking acrylate emulsion, styrene-butadiene emulsion and thickening emulsion, and stir at room temperature for 5 minutes;

[0041] S2, ...

Embodiment 2

[0046] A node waterproof sealant paste for polymer coils, consisting of the following components calculated in parts by weight:

[0047] Low Tg acrylate copolymer emulsion (PLEXTOL A 315) 30 parts;

[0048] 12 parts of self-crosslinking acrylate emulsion (Neocryl A-1127);

[0049]7 parts of styrene-butadiene emulsion (Lipaton SB 29Y57);

[0050] Viscosifying emulsion (Snowtack SE 780G) 8 parts;

[0051] 37 parts of filler (1000 mesh superfine barium sulfate);

[0052] Dispersant 0.3 part;

[0053] 0.3 parts of AMP-95;

[0054] 4.6 parts of water;

[0055] 0.3 part of cellulose ether;

[0056] 0.2 parts of anti-corrosion and anti-mold agent;

[0057] 0.3 part of defoamer.

[0058] The preparation process of the node waterproof sealant for polymer coils is the same as that in Example 1, and will not be repeated here.

Embodiment 3

[0060] A node waterproof sealant paste for polymer coils, consisting of the following components calculated in parts by weight:

[0061] Low Tg acrylate copolymer emulsion (PLEXTOL A 315) 32 parts;

[0062] 7 parts of self-crosslinking acrylate emulsion (Neocryl A-1127);

[0063] 6 parts of styrene-butadiene emulsion (Lipaton SB 29Y57);

[0064] Viscosifying emulsion (Snowtack SE 780G) 6 parts;

[0065] 42 parts of filler (1000 mesh superfine barium sulfate);

[0066] 0.5 parts of dispersant;

[0067] 0.3 parts of AMP-95;

[0068] 5.4 parts of water;

[0069] 0.2 part of cellulose ether;

[0070] 0.2 parts of anti-corrosion and anti-mold agent;

[0071] 0.4 part of defoamer.

[0072] The preparation process of the node waterproof sealant for polymer coils is the same as that in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com