Synthesis method of 2, 9-substituted 4-halogenated-1, 10-phenanthroline

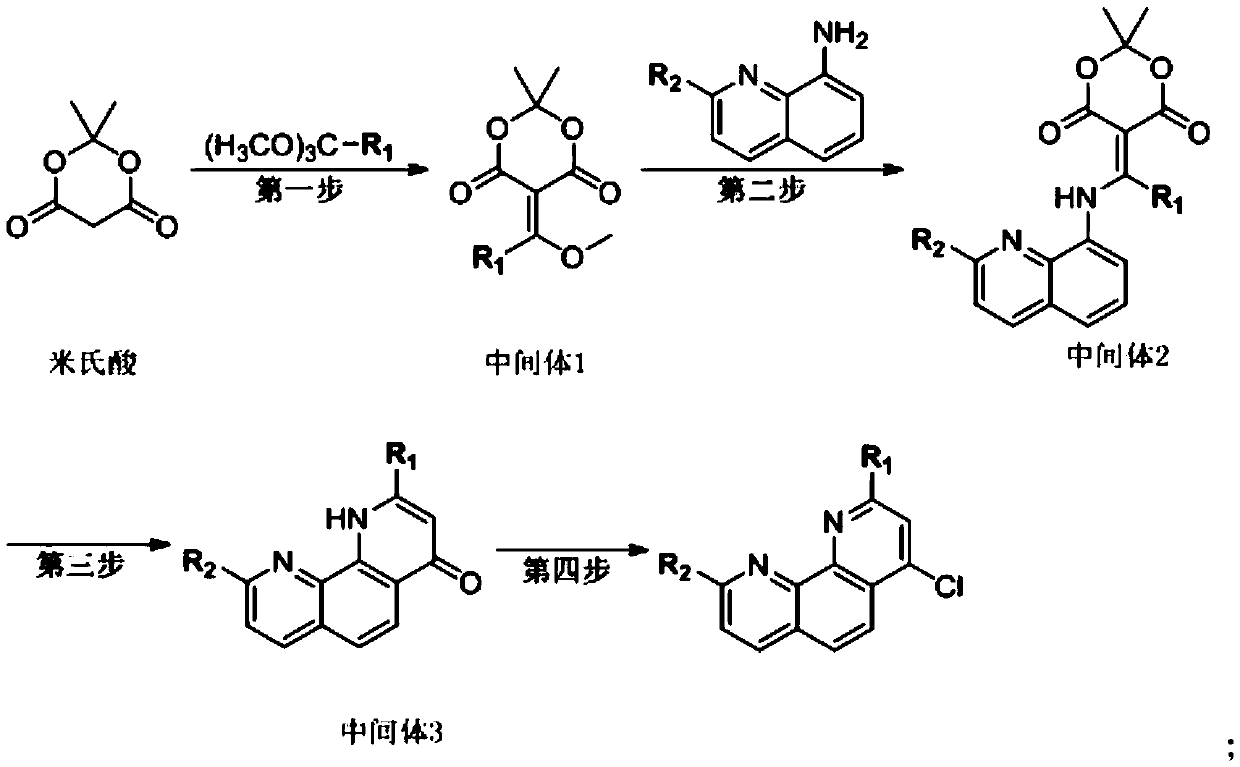

A technology of o-phenanthroline and its synthesis method, which is applied in the field of synthesis of 4-halogenated-1,10-phenanthroline, which can solve the problems of low conversion rate, difficulty in purification, unfavorable industrial production, etc., so as to improve the conversion rate , improve the yield, and benefit the effect of industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of synthetic method of 4-chloro-2,9-dimethyl-1,10-phenanthroline, comprising the following steps:

[0028] first step:

[0029]

[0030] Under argon protection, add 273.41 g of trimethyl orthoacetate and 163.99 g of Michaelis acid to a 1L three-necked flask equipped with a mechanical stirrer, a thermometer, a condenser tube, a water separator, and a drying tube, start stirring and heating, and heat up (0.5 h) After reflux reaction at 78°C for 2 hours (75ml of low-boiling point by-products are fractionated while reacting), turn off the heating and cool down to 55°C for use;

[0031] Step two:

[0032]

[0033] Add 60.00 g of 2-methyl-8-aminoquinoline to the reaction solution in the first step, control the temperature at 60°C for 3 hours to stop the reaction, cool the reaction solution to 35°C for 30 minutes, and then filter to obtain a filter cake The crude yellow solid was beaten with 120.00g trimethyl orthoacetate at 35°C for 10min, filtered, and the fil...

Embodiment 2

[0041] A kind of synthetic method of 4-bromo-2,9-dimethyl-1,10-phenanthroline, comprising the following steps:

[0042] first step:

[0043]

[0044] Under argon protection, add 546.82 g of trimethyl orthoacetate and 163.99 g of Michaelis acid to a 1L three-necked flask equipped with a mechanical stirrer, a thermometer, a condenser tube, a water separator, and a drying tube, start stirring and heating, and heat up (0.5 h) After reflux reaction at 98°C for 4 hours (83ml of low-boiling point by-products are fractionated while reacting), turn off the heating and cool down to 65°C for use;

[0045] Step two:

[0046]

[0047]Add 30.00 g of 2-methyl-8-aminoquinoline to the reaction solution in the first step, and react at a temperature of 40°C for 5 hours to stop the reaction; cool the reaction solution to 25°C and keep stirring for 30 minutes, then filter to obtain a filter cake The crude yellow solid was beaten with 60.00g trimethyl orthoacetate at 25°C for 10min, filtere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com